Textile cleaning device

A cleaning device and textile technology, applied in textiles and papermaking, equipment configuration for processing textile materials, mechanical cleaning, etc., can solve problems such as poor cleaning effect, hair balls, and fabric wrinkles, so as to improve cleaning effect and work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

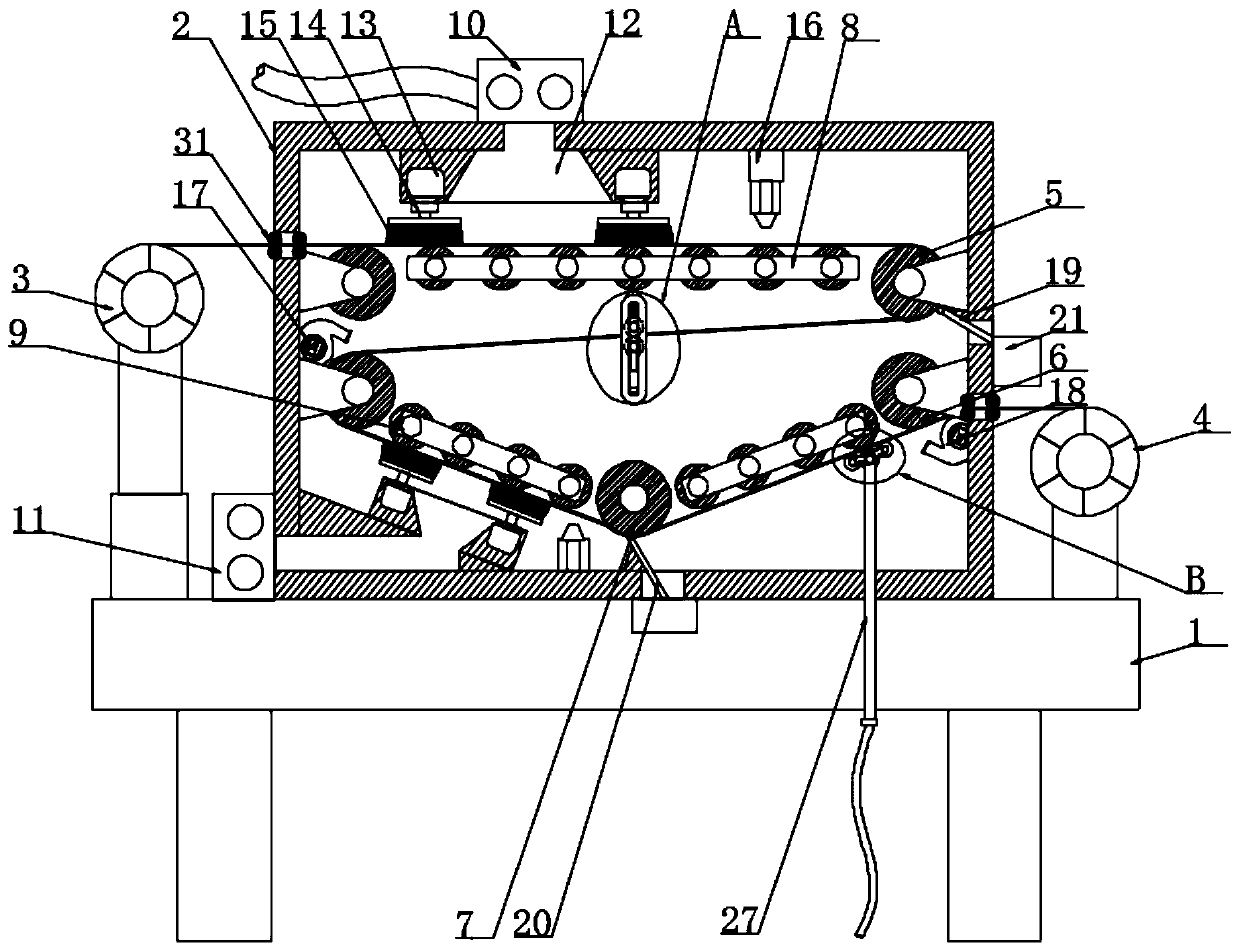

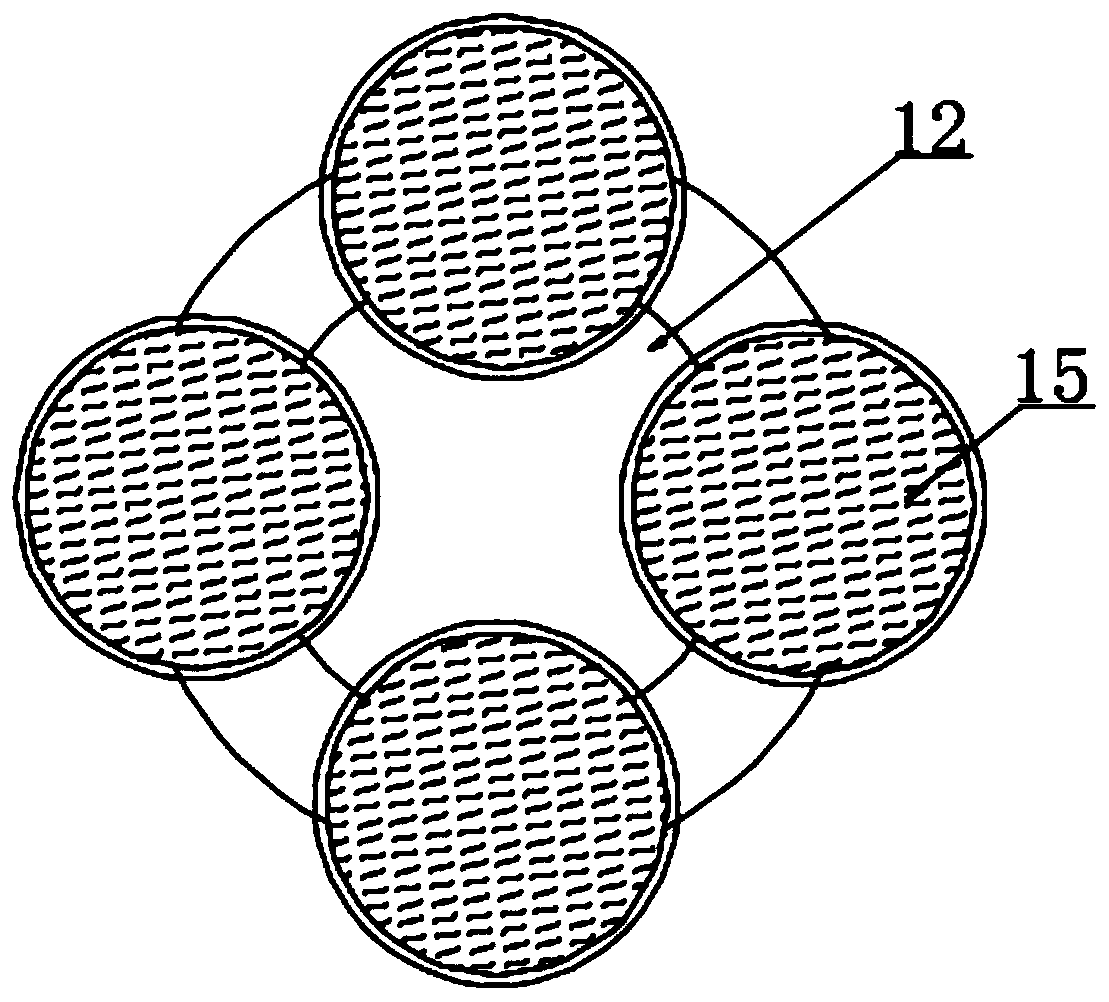

[0025] according to Figure 1-4 A textile cleaning device shown includes a frame 1, a box body 2 is arranged on the top of the frame 1, and an unwinding roller 3 is arranged on one side of the box body 2, and the box body 2 is far away from the unwinding roller 3 One side of the box body 2 is provided with a winding roller 4, and the inside of the box body 2 is provided with two symmetrically distributed first turning rollers 5, and the bottom of the first turning roller 5 is provided with two symmetrically distributed second turning rollers 6, A third turning roller 7 is arranged between the two second turning rollers 6, and a first bracket 8 is fixedly connected between the two first turning rollers 5, and the third turning roller 7 is connected to the two first turning rollers 5. The second support bracket 9 is arranged between the two steering rollers 6, the first dust suction pump 10 is provided on the top of the box body 2, the second dust suction pump 11 is arranged on ...

Embodiment 2

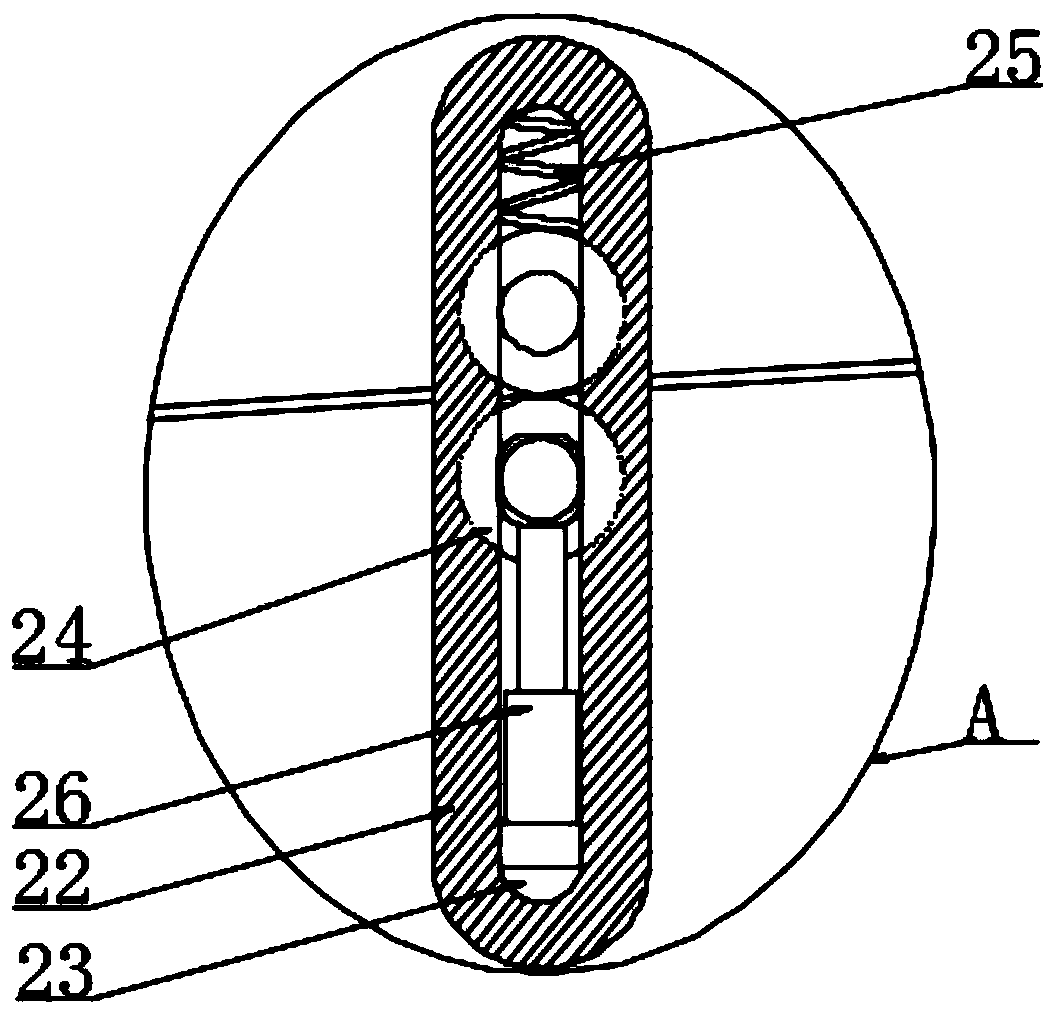

[0028] according to figure 1 and 3 As shown in a textile cleaning device, a tension adjustment device is provided between the two first turning rollers 5 and the two second turning rollers 6, and the tension adjustment device includes two symmetrically distributed fixing plates 22 A chute 23 runs through one side of the fixed plate 22, and two parallel adjusting rollers 24 are slidably connected in the chute 23, a compression spring 25 is provided at the top of the chute 23, and a compression spring 25 is provided at the bottom of the chute 23. There is a second cylinder 26, through the tension adjustment device, the output end of the second cylinder 26 pushes the slider to make the adjustment roller 24 slide in the chute 23, under the action of the compression spring 25, the two adjustment rollers 24 clamp the woven fabric, It can easily adjust the tightness of the textile and improve the cleaning effect of the textile;

[0029] according to image 3As shown in a textile c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com