Modified phenolic resin, composite material, and preparation methods of modified phenolic resin and composite material

A technology of phenolic resin and composite materials, which is applied in the field of composite materials, can solve problems affecting the molding process and mechanical properties, and achieve the effects of eliminating free air layers, uniform expansion coefficient, and reducing thermal conductivity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

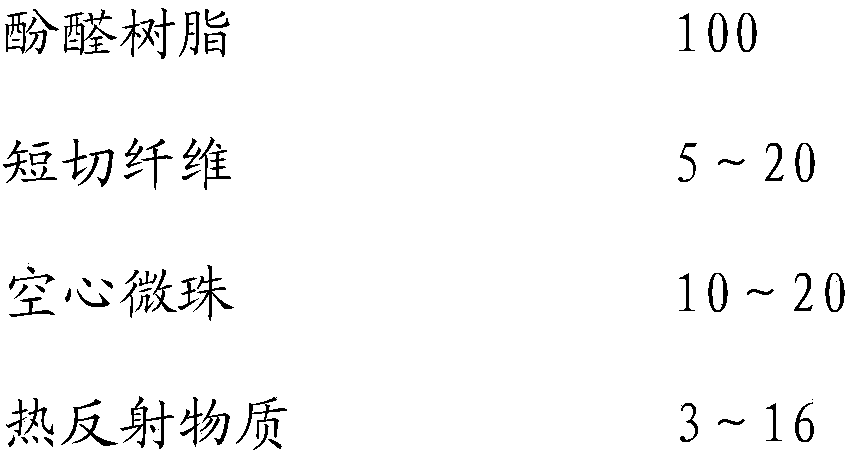

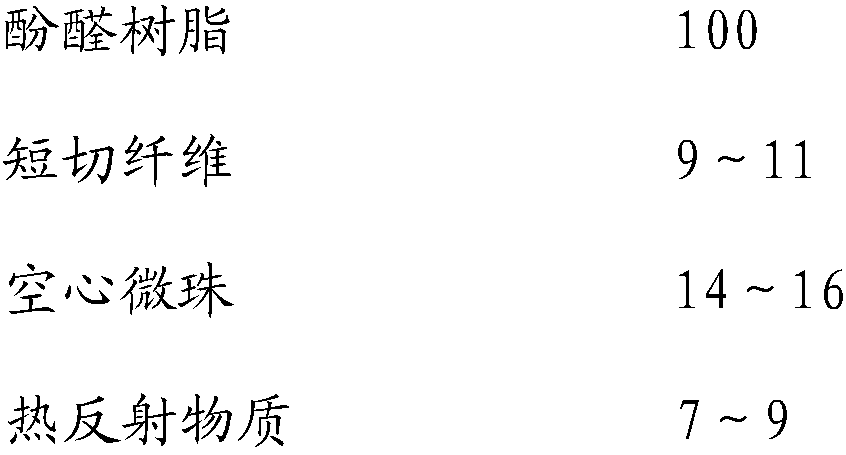

[0068] Modified phenolic resin ratio (mass ratio)

[0069]

[0070] The preparation method is as follows:

[0071] 1) Blending treatment of ceramic hollow microspheres

[0072] The opal shale ore is crushed, pulverized, ground and separated to produce opal masterbatches with a diameter of about 100um (ceramic hollow microspheres are generally 10-30um in diameter), and the opal masterbatches are dried at 120°C for 2 hours , the dried opal masterbatch and ceramic hollow microspheres were mixed in a high-speed mixer for 2 hours to make them uniform, and after standing for 30 minutes to cool, the ceramic hollow microspheres were sieved from the mixture.

[0073] 2) Fabric preparation

[0074] Select 85tex C-type quartz glass fiber, spiral curly phenolic fiber 20S / 3, and aramid fiber-Kevlar K49 to weave according to the quantity ratio (number ratio) of 1:1:1, and the warp and weft density of the woven yarn: 9 root / cm, area density 150g / ㎡.

[0075] 3) Preparation of modified ...

Embodiment 2

[0081] Except fabric, other proportioning and step are with embodiment 1, and the specific performance of the test sample of this example is shown in Table 1.

[0082] Fiber fabric:

[0083] Select 85tex C-type quartz glass fiber and spiral curly phenolic fiber 20S / 3 for weaving according to the quantity ratio (number ratio) of 5:4. The warp and weft density of the weaving yarn is 9 threads / cm, and the surface density is 150g / ㎡.

[0084] Table 1

[0085]

[0086]

[0087] It can be seen from Table 1 that the use of different fabrics has little effect on the thermophysical properties of the composite material, but the addition of aramid fiber to the fabric can improve the mechanical properties of the composite material such as tensile strength, and the addition of aramid fiber can also greatly improve the mechanical properties of the composite material. It is good to improve the interlayer performance of the product.

Embodiment 3、4

[0089] Heat reflective material (TiO2) in embodiment 3,4 2 ) addition number of parts is 3 and 16, and other is with embodiment 1, and the specific performance of the test sample that obtains is shown in Table 2.

[0090] Table 2

[0091]

[0092] It can be seen from Table 2 that the addition of heat reflective substances can effectively improve the thermophysical properties of composite materials, and the optimal mass ratio of phenolic resin to heat reflective substances is around 100:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com