Method for recycling C-2 in dry gas of refinery

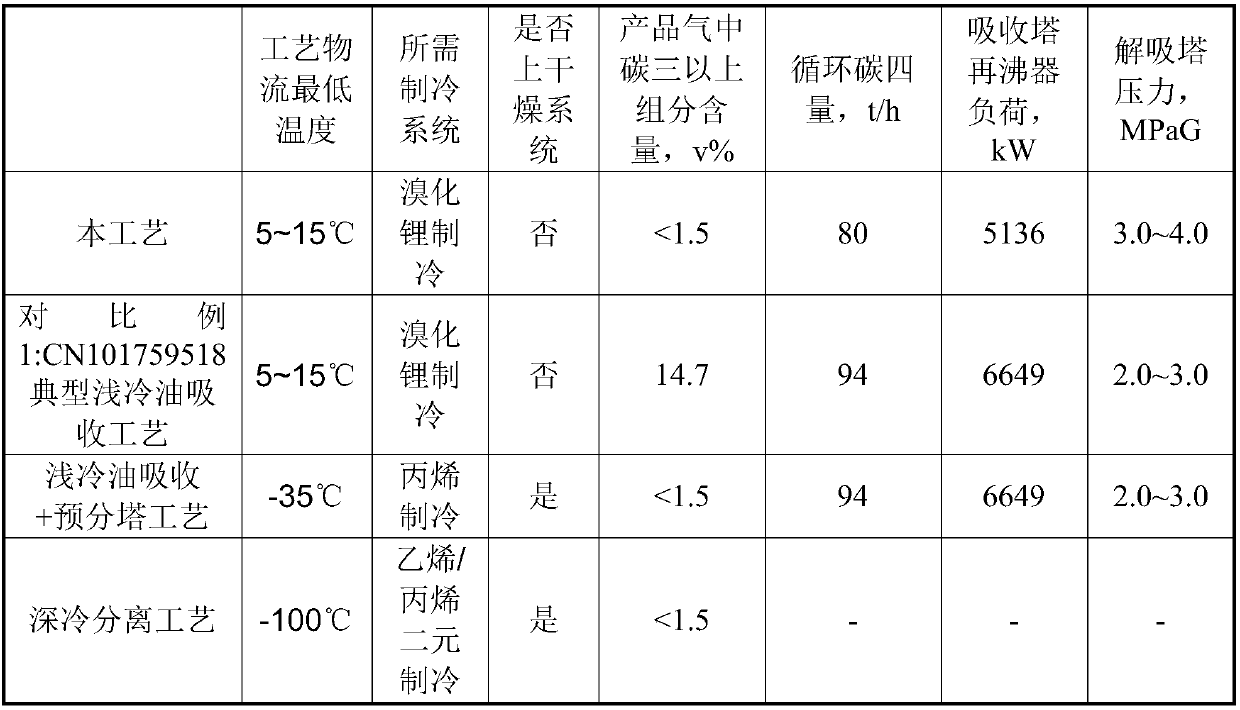

A refinery dry gas and dry gas technology, applied in chemical instruments and methods, hydrocarbons, absorption purification/separation, etc., can solve the problem of difficult separation of carbon 2 and carbon 3 components, large circulation of carbon 4 absorbent, Large investment and other issues, to achieve the effect of easy acquisition, high recovery rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This example is used to illustrate the method for recovering carbon dioxide in refinery dry gas according to the present invention.

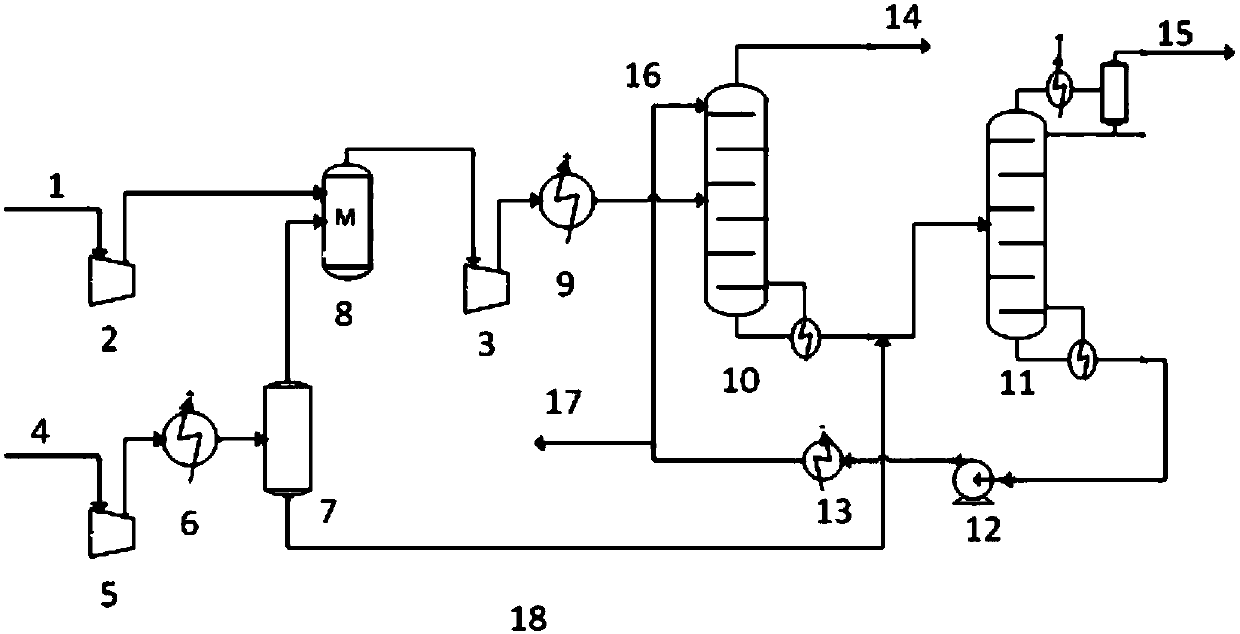

[0072] The dry gas (pressure 0.25MPaG) from the PX unit from the refinery aromatics complex is supplied to the aromatics dry gas compressor 5 to increase the pressure to 2.5MPaG. The pressurized dry gas is cooled to 15°C by the lithium bromide refrigerator 6, and the gas-liquid phase separation is carried out in the liquid separation tank 7, and the gas phase at the top of the liquid separation tank 7 is sent to the inter-stage buffer tank 8 of the coking dry gas compressor.

[0073] The coking dry gas 1 (pressure 0.80MPaG) from the delayed coking unit of the refinery is boosted to 2.0MPaG by the coking dry gas compressor section 2, and then supplied to the coking dry gas compressor section together with the gas phase at the top of the liquid separation tank 7 The gas phase at the top of the buffer tank 8 is boosted to 4.0MPaG through the...

Embodiment 2

[0079] This example is used to illustrate the method for recovering carbon dioxide in refinery dry gas according to the present invention.

[0080] The dry gas (pressure 0.25MPaG) from the PX unit from the refinery aromatics complex is supplied to the aromatics dry gas compressor 5 to increase the pressure to 4.5MPaG. The pressurized dry gas is cooled to 15°C by the lithium bromide refrigerator 6, and the gas-liquid phase separation is carried out in the liquid separation tank 7, and the gas phase at the top of the liquid separation tank 7 is sent to the inter-stage buffer tank 8 of the coking dry gas compressor.

[0081] The coking dry gas 1 (pressure 0.80MPaG) from the delayed coking unit of the refinery is boosted to 2.0MPaG by the first section 2 of the coking dry gas compressor, and then supplied to the coking dry gas compressor section together with the gas phase at the top of the liquid separation tank 7 The gas phase at the top of the buffer tank 8 is boosted to 5.0 MP...

Embodiment 3

[0087] This example is used to illustrate the method for recovering carbon dioxide in refinery dry gas according to the present invention.

[0088] The dry gas (pressure 0.25MPaG) from the PX unit from the refinery aromatics complex is supplied to the aromatics dry gas compressor 5 to increase the pressure to 3.0MPaG. The pressurized dry gas is cooled to 5°C by the lithium bromide refrigerator 6, and the gas-liquid phase separation is carried out in the liquid separation tank 7, and the gas phase at the top of the liquid separation tank 7 is sent to the inter-stage buffer tank 8 of the coking dry gas compressor.

[0089] The coking dry gas 1 (pressure 0.80MPaG) from the delayed coking unit of the refinery is boosted to 2.0MPaG by the coking dry gas compressor section 2, and then supplied to the coking dry gas compressor section together with the gas phase at the top of the liquid separation tank 7 The gas phase at the top of the buffer tank 8 is boosted to 3.5MPaG through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com