Multi-material in-mold assembling method

An in-mold assembly and multi-material technology, applied in the direction of coating, etc., can solve the problems of consuming manpower and material resources, workshop space, inability to carry out processes, and large limitations, so as to improve stability and tightness of cooperation, save manpower and material resources and The effect of factory space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

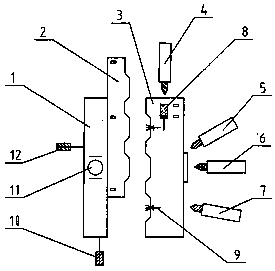

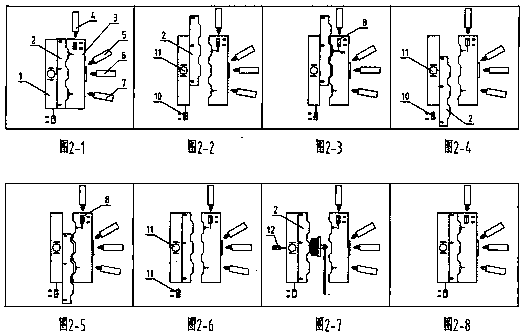

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] As shown in Figure 1, a multi-material in-mold assembly method includes a movable mold (1), a sub-mould (2), a fixed mold (3) and injection devices one (4) and two injection devices (5) arranged around them. ), injection device three (6), and injection device four (7); the movable mold (1) is provided with a sub-mold positioning device (10), a sub-mold driving device (11) and an ejector device (12); the fixed mold (3) is provided with a product assembly mechanism (8) and a blowing device (9); it is characterized by: the movable mold (1), the sub-mould (2), the fixed mold (3) after the mold closing is completed, the injection device (4) ), injection device two (5), injection device three (6), and injection device four (7) inject into the fixed mold (3) at the same time. Drive the sub-mold (2) to meet the assembly requirements of differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com