Welding technology of high strength lightweight steel

A welding process and steel technology, applied in the field of high-strength and light-weight steel welding process, to achieve the effects of improving purity, reducing welding stress and deformation, and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

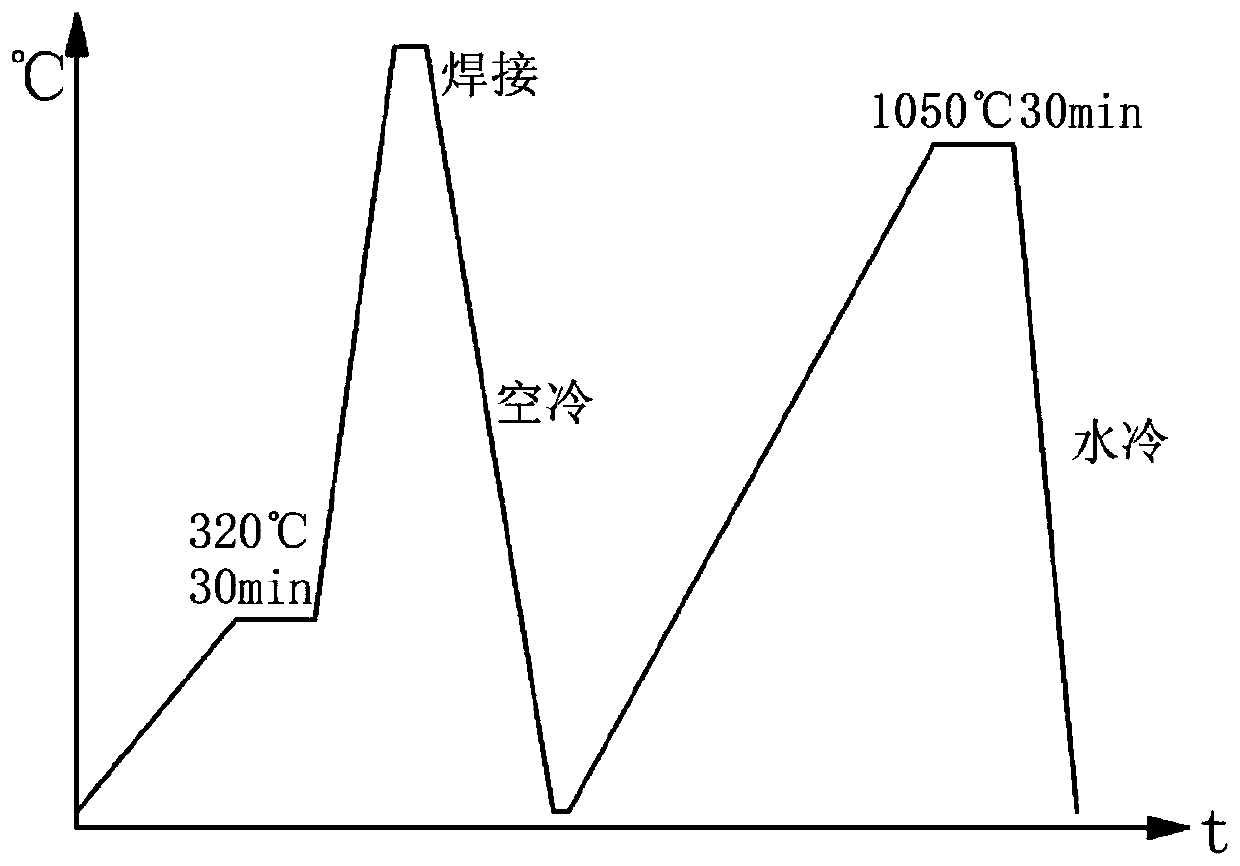

[0045] The following is further described in detail through specific implementation methods:

[0046] The invention provides a high-strength light-weight steel welding process, wherein the chemical formula of the steel used in the invention is Fe-28Mn-10Al-0.8C, and its raw materials include pure iron with a mass percentage of 60.36% and ferrovanadium with a mass percentage of 0.09% , 0.11% ferroniobium, 0.85% graphite carbon, 28% electrolytic manganese, 10.5% aluminum block and 0.09% pure titanium. The preparation process of the steel includes the following steps:

[0047] Step (1): charging, carry out derusting and degreasing treatment to the surface of above-mentioned raw material before charging, after the mass percentage is 60.36% pure iron, 0.09% ferrovanadium, 0.11% ferroniobium and 0.05% The graphite carbon is placed in the crucible of the vacuum induction furnace, 28% electrolytic manganese, 0.8% graphite carbon, 10.5% aluminum block and 0.09% pure titanium are respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com