Preparation method of inhalation dry powder composition

A technology of composition and dry powder, which is applied in the direction of drug combination, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. It can solve problems such as hydrolysis instability, high industrial production costs, and reduced interparticle forces , to achieve the effects of excellent inhalation characteristics, strong stability of formulation characteristics, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of micronized tiotropium bromide

[0033] Tiotropium bromide monohydrate and tiotropium bromide anhydrate are micronized respectively in a jet mill, and the pulverization pressure is 0.6Mpa, and the resulting product particle diameter is D 50 Reach below 5μm.

Embodiment 2

[0034] Embodiment 2: Preparation of micronized formoterol fumarate

[0035] Formoterol fumarate dihydrate and formoterol fumarate were micronized in a jet mill respectively, the crushing pressure was 0.6Mpa, and the particle size of the obtained product was D 50 Reach below 5μm.

Embodiment 3

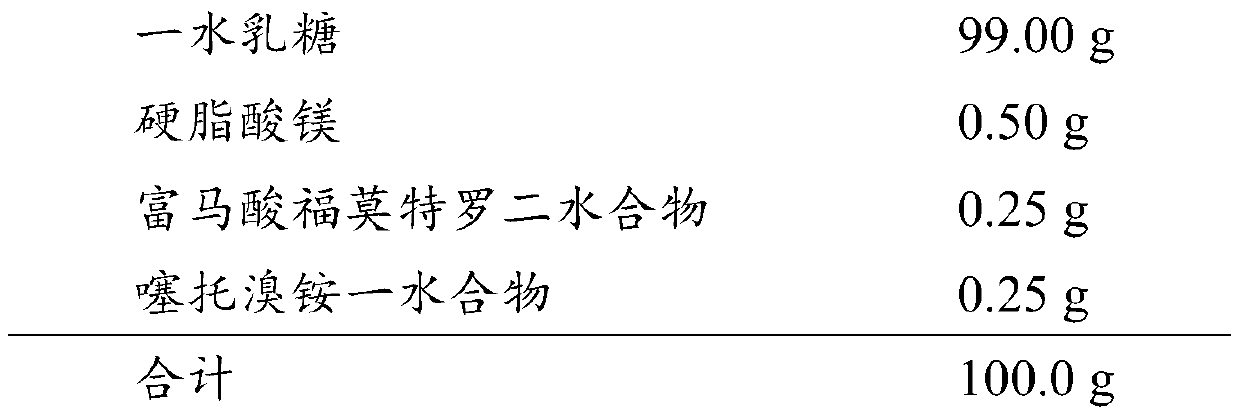

[0036] Embodiment 3: take lactose monohydrate as pharmaceutical carrier, magnesium stearate as lubricant, tiotropium bromide formol for inhalation Tero dry powder preparation

[0037] Weigh lactose monohydrate and magnesium stearate (D 50= 3.01 μm) mixed in a three-dimensional mixer for 10min, transferred to a high-speed mixer, mixed for 10min with a cutter linear speed of 10m / s, and left to stand properly to prepare a carrier compound, and then added the micronized thiamine prepared in Example 1 Trotropium bromide monohydrate and the formoterol fumarate dihydrate prepared in Example 2 were mixed in a high-speed mixer for 10 minutes at a cutter speed of 10 m / s, and finally mixed in a three-dimensional mixer for 20 minutes.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com