Lead halide perovskite poly-silicon thin piece and fabrication method thereof

A technology of perovskite and flakes, applied in the field of lead halide perovskite polycrystalline flakes and its preparation, which can solve the problems of inability to apply thick film preparation and waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

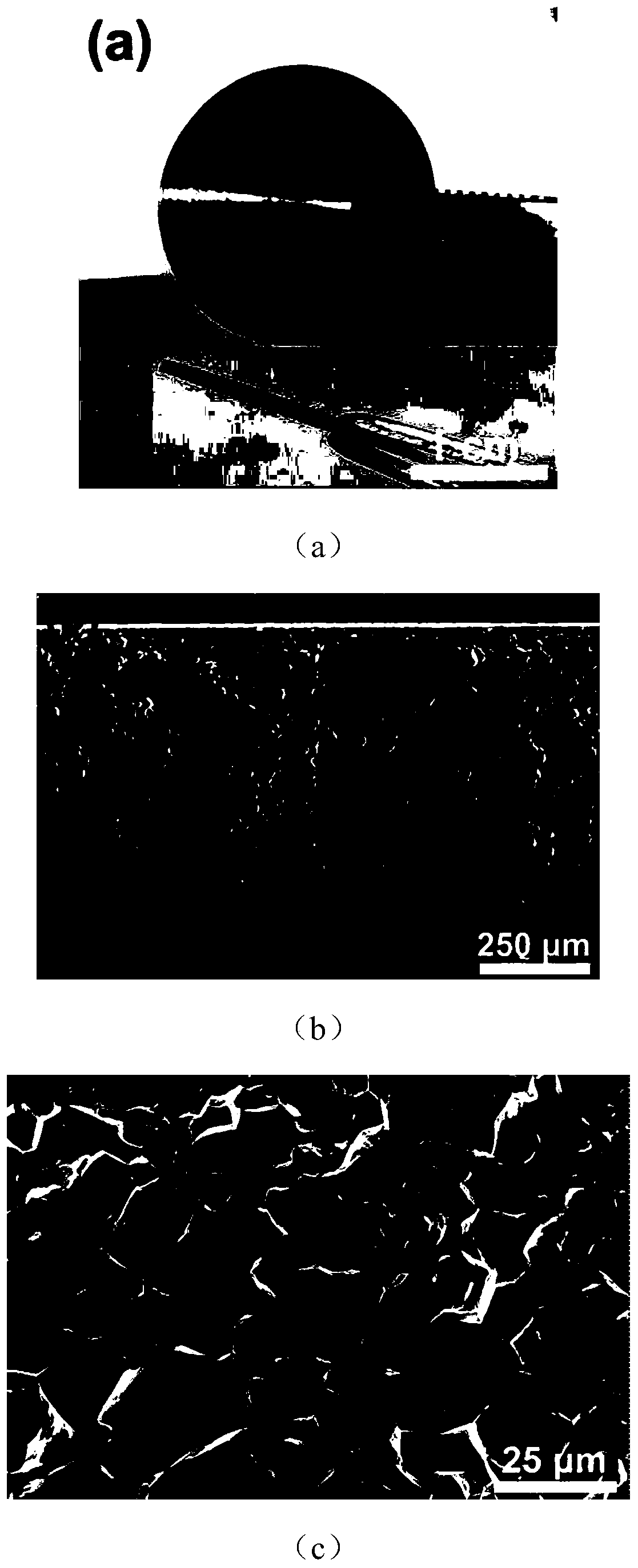

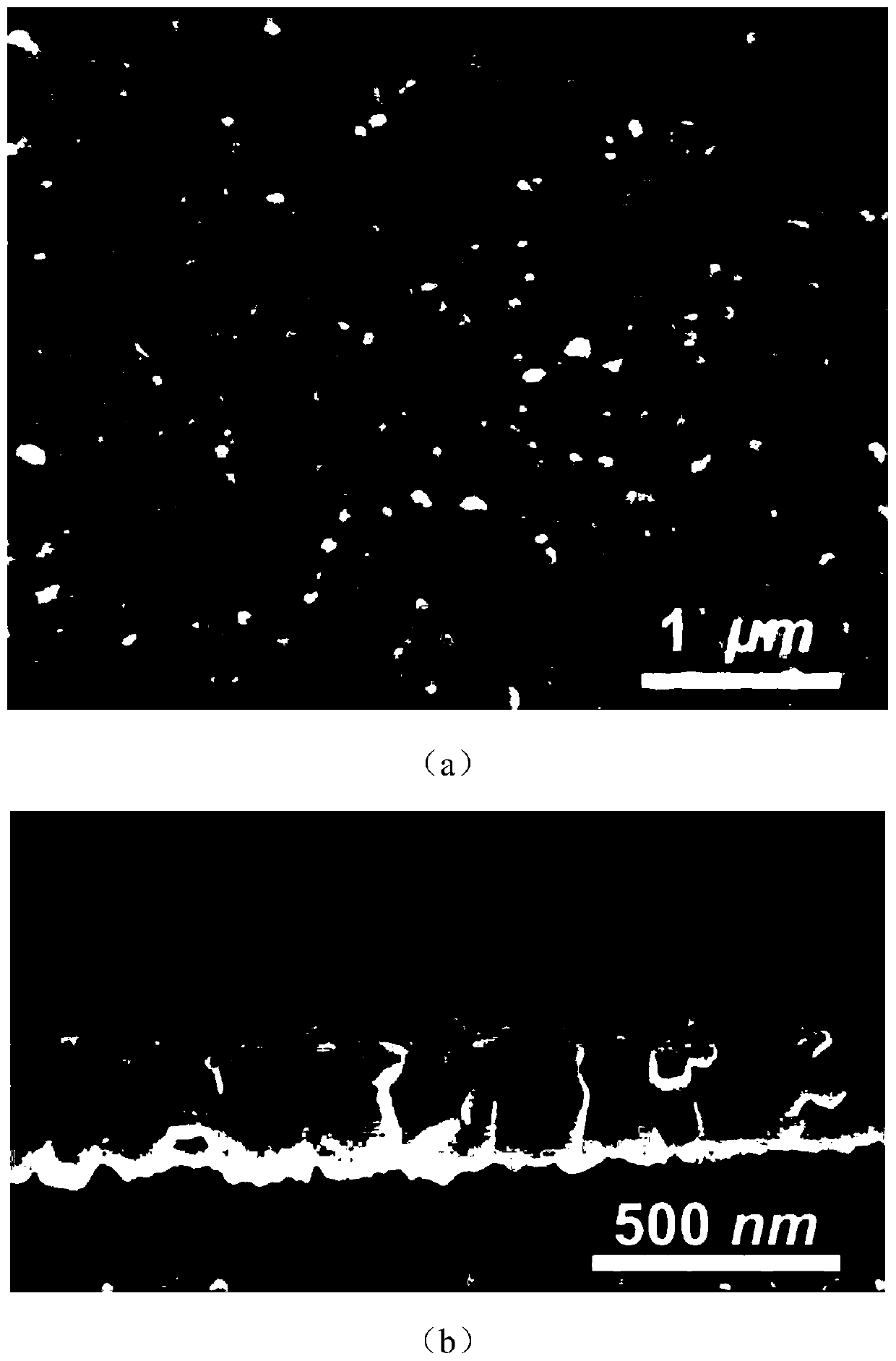

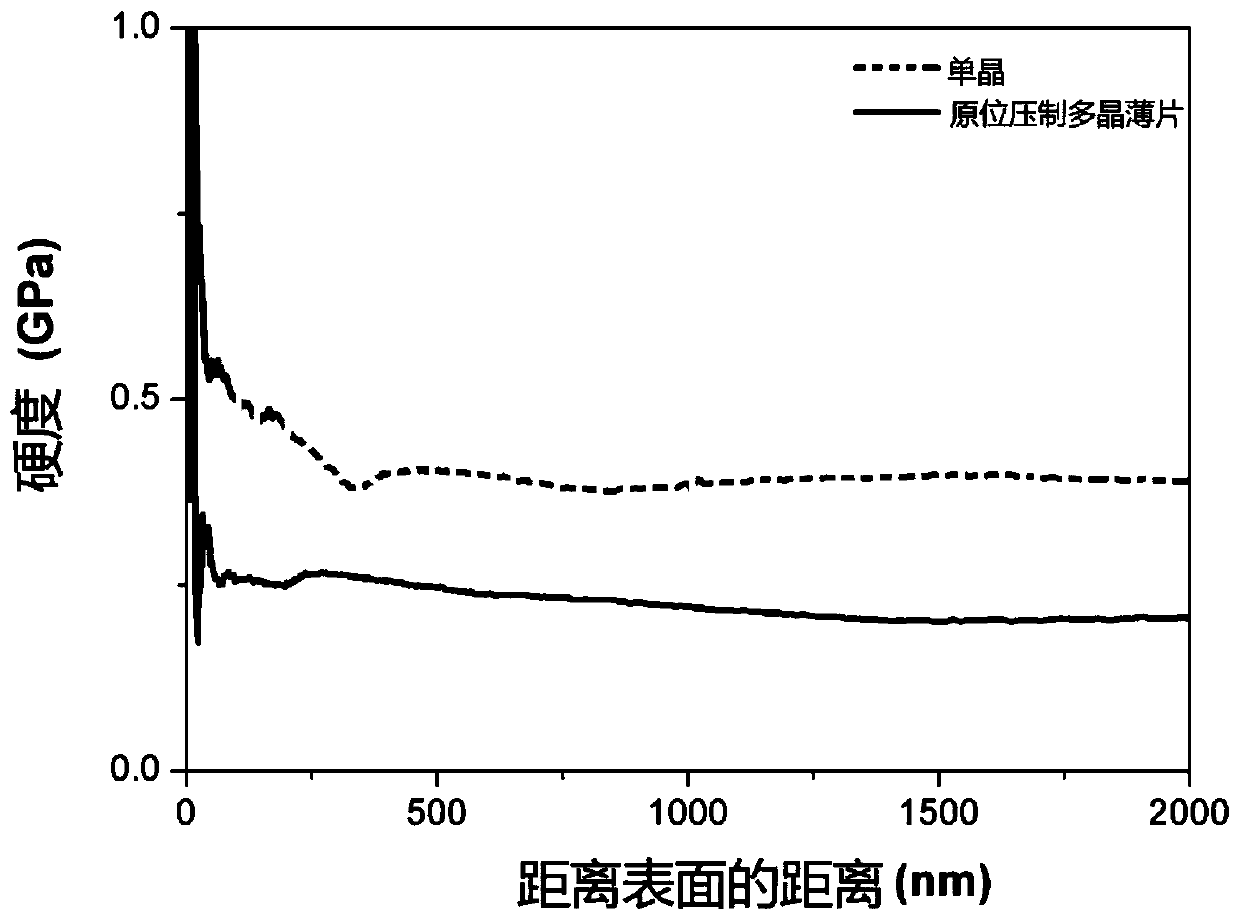

[0048] Weigh PbI with a molar ratio of 1:1 2 and CH 2 NH 3 The powder of I is ground by agate to mix the two; put the mixed raw materials into a square mold, apply a pressure of 0.1MPa, and simultaneously heat the mold to 100°C for 60min, and press the raw materials into flakes to obtain more The precursor of the perovskite flake, after the reaction is completed and the mold is cooled, the sample is taken out to obtain a perovskite polycrystalline flake with a thickness of 10 μm.

Embodiment 2

[0050] Weigh CsBr and PbBr with a molar ratio of 1:1 2 Grind the powder with a glass mortar to mix the two; put the mixed raw materials into a circular mold, apply a pressure of 0.5MPa, and heat the mold to 120°C for 55 minutes, and press the raw materials into flakes. The precursor of the polycrystalline flake was obtained, and after the reaction was completed and the mold was cooled, the sample was taken out to obtain a perovskite polycrystalline flake with a thickness of 100 μm.

Embodiment 3

[0052] Weigh CsCl and PbCl with a molar ratio of 1:1 2 Grind the powder with a ceramic mortar to mix the two; put the mixed raw materials into a triangular mold, apply a pressure of 1 MPa, and heat the mold to 130°C for 50 minutes, and press the raw materials into flakes to obtain multiple The precursor of the crystal flake, after the reaction is completed and the mold is cooled, the sample is taken out to obtain a perovskite polycrystalline flake with a thickness of 200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com