Ultraviolet-resistant moisture absorbing and heating protein tencel fiber and preparation method thereof

A technology of moisture absorption and heating and tencel fibers, which is applied in the field of textile fibers, can solve the problems of fabric wearability damage, fabric anti-ultraviolet performance reduction, moisture absorption and heating fiber strength damage, etc., to achieve good skin affinity and good UV absorption , the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

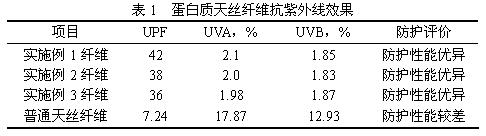

Embodiment 1

[0040] Take 200g of cellulose pulp, pulverize it and disperse it in 800g of 50wt% NMMO solution, raise the temperature to 90°C, and stir evenly for 60min to prepare a cellulose spinning mother liquor with a cellulose content of 20wt%.

[0041] Add 50 g of mercaptobenzoic acid to 1000 g of cellulose spinning mother liquor, add 1 g of ZSM-5 molecular sieve catalyst, raise the temperature to 45° C., stir and react for 60 minutes, and prepare mercapto compound modified cellulose spinning mother liquor.

[0042] Take 100g of Australian wool that removes impurities and washes, add 300g of deionized water, and use NaHCO 3Adjust the pH value of the solution to 7-8, heat to 50°C, add 1g of disulfide bond reductase and 2g of solid protease, keep the temperature uniform and stir for 90 minutes to dissolve the wool completely, and filter to prepare wool with a keratin content of 25wt%. Keratin solution. The color of the wool keratin solution made is slightly black, and has a slightly pun...

Embodiment 2

[0051] Take 100g of cellulose pulp, pulverize it and disperse it in 600g of 50wt% NMMO solution, raise the temperature to 80°C, and stir evenly for 120min to prepare a cellulose spinning mother liquor with a cellulose content of 14.3wt%.

[0052] Add 20 g of 2-mercaptobutyric acid and 20 g of mercaptobenzoic acid to 700 g of cellulose spinning mother liquor, then add 1 g of ZSM-5 molecular sieve catalyst, heat up to 50 ° C and stir for 65 minutes to prepare mercapto compound modified cellulose spinning mother liquor.

[0053] Get the cleaned goat hair 100g that removes impurity, add 400g deionized water, with NaHCO 3 Adjust the pH value of the solution to 7-8, heat to 45°C, add 1g of disulfide bond reductase and 2g of solid protease, keep the temperature uniform and stir for 80 minutes to dissolve the wool, filter it, and prepare wool with a keratin content of 20wt%. Keratin solution.

[0054] 100 g of wool keratin solution was added to 700 g of modified cellulose spinning mo...

Embodiment 3

[0059] Take 100g of cellulose pulp, pulverize it and disperse it in 700g of 50wt% NMMO solution, raise the temperature to 85°C, and stir evenly for 60min to prepare a cellulose spinning mother liquor with a cellulose content of 12.5wt%.

[0060] Add 25g each of 2,3-dimercaptopropionic acid and 3-mercaptopropionic acid to 800g of cellulose spinning mother liquor, then add 1.2g of Y molecular sieve catalyst, heat up to 60°C and stir for 45min to prepare mercapto compound modified cellulose spinning silk mother liquor.

[0061] Get 100g of cleaned wool scraps to remove impurities, add 700g deionized water, and use NaHCO 3 Adjust the pH value of the solution to 7-8, heat to 45°C, add 1.5g disulfide bond reductase and 2.5g solid protease, keep the temperature uniform and stir for 90 minutes to dissolve all the wool, filter, and prepare a keratin content of 12.5wt % wool keratin solution.

[0062] Add 100 g of wool keratin solution into 800 g of modified cellulose spinning mother ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com