Shutter

A shutter and blade technology, applied in the field of shutters, can solve the problems of low installation efficiency, great installation difficulty, affecting the overall strength and aesthetics of shutters, etc., and achieve the effects of convenient installation and adjustment, saving production costs, and simple and reliable overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

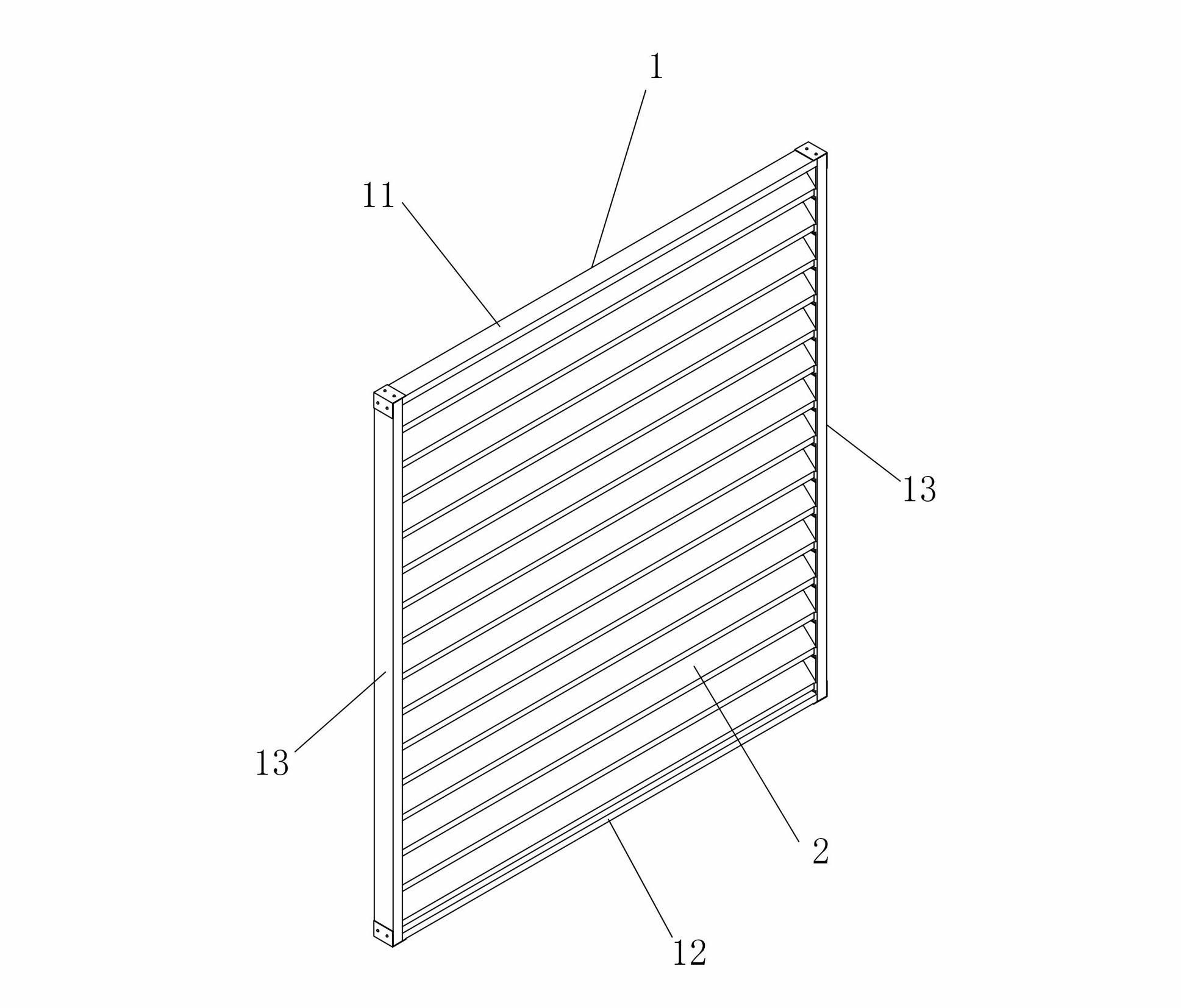

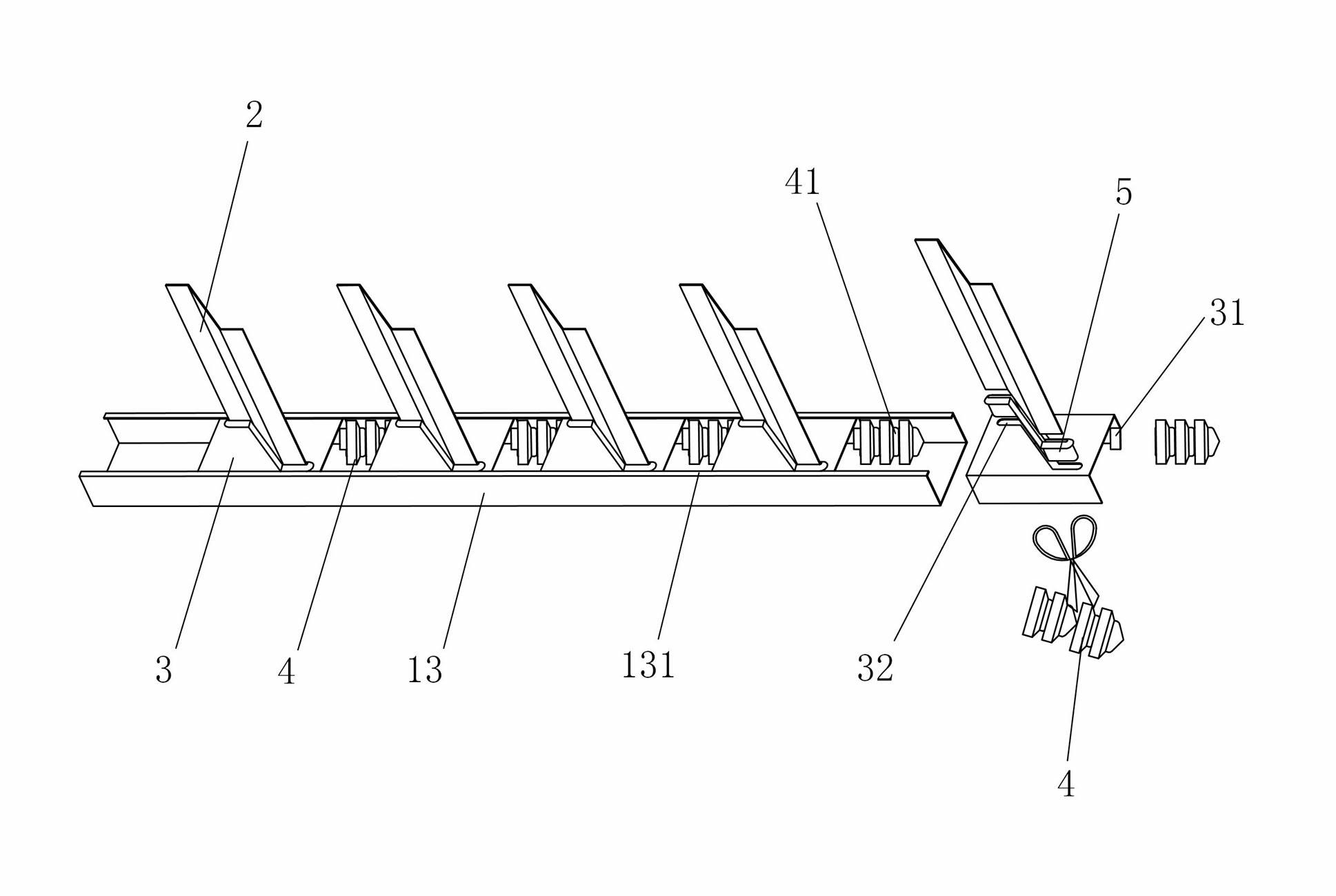

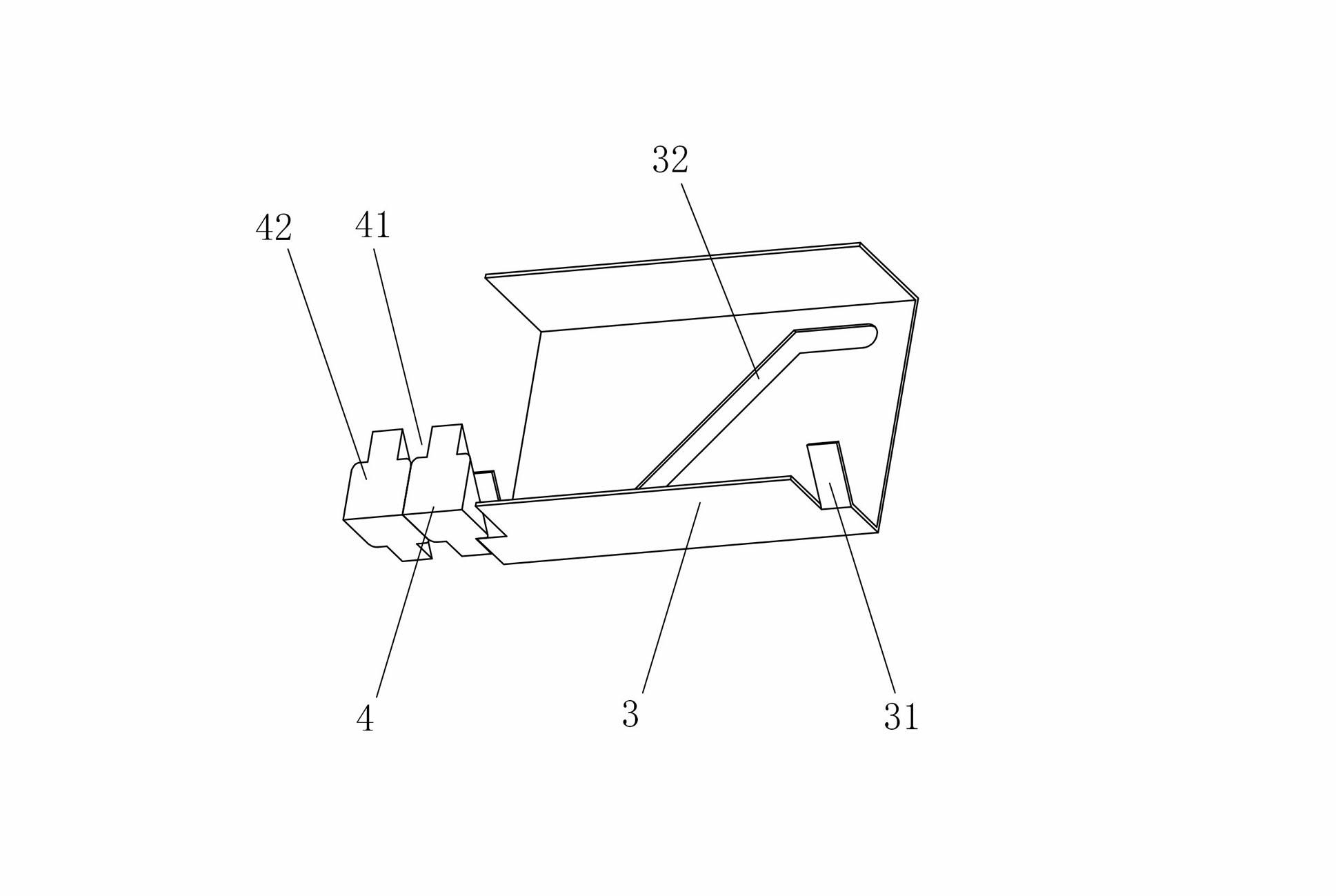

[0020] Figure 1 to Figure 3 It shows an embodiment of a louver of the present invention, the louver includes a plurality of blades 2, and a frame 1 formed by connecting a top beam 11, a bottom beam 12 and two side beams 13, and the two side beams 13 They are all channel-shaped beams, and the notch is set toward the inner side of the frame body 1. A sliding connector 3 is sleeved on both ends of each blade 2, and the blade 2 is installed between two side beams 13 through the sliding connector 3. , the sliding connecting piece 3 is slidably arranged in the notch of the side beam 13, and a clip bar 4 for adjusting the distance is clamped between two adjacent sliding connecting pieces 3. The louver of the present invention installs the blade 2 between the two side beams 13 through the sliding connector 3, and adjusts the distance between the blades 2 by clamping the clip 4 between the two adjacent sliding connectors 3, Its overall structure is simple and reliable, and the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com