A resin composite single-pipe tower connection structure

A resin composite material and connection structure technology, applied in towers, building types, buildings, etc., can solve the problems of bulky structures and insufficient firmness, and achieve the effects of reducing production costs, convenient and simple installation, and simple appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

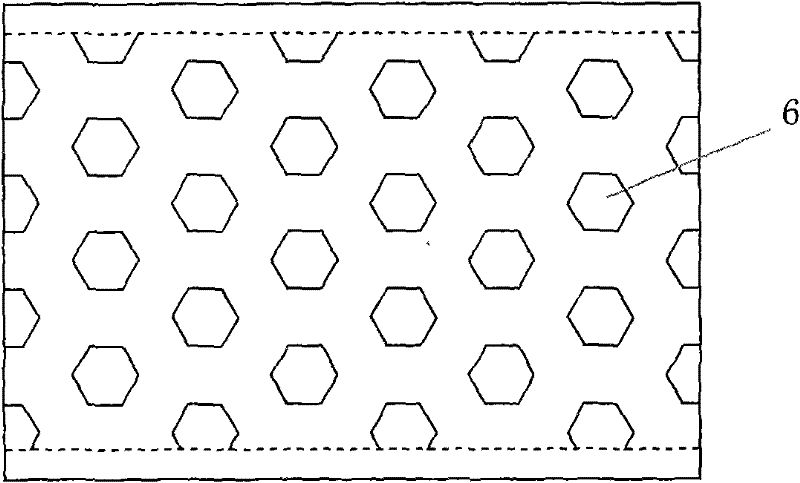

[0021] Such as Figure 1-Figure 18 As shown, the resin composite material single-tube tower connection structure includes a tower body 1, an inner lining pipe 5, and a flange plate 2. One end of the inner lining pipe 5 is embedded in the inner ring of the flange plate 2 and welded, and the inner lining pipe 5 The outer tube body is provided with horizontal shallow grooves 7 or honeycomb holes 6 to enhance the fastness of the resin composite material winding. The two ends of the tower body 1 and the fixed pipe fittings are uniformly wound and formed by resin composite material, which is used for the cable flange The diameter of the disk 10 is larger than the diameter of the flanges 2 at both ends of the pipe body. The outer ring of the bolt hole 3 on the cable flange 10 is provided with a cable hole 11. The cable hole 11 is centered on the center of the flange plate 2 and is uniform. Distribution, the number of cable holes 11 is determined according to construction needs.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com