Selenium drum preparation method combining high-power pulse magnetron sputtering technology

A high-power pulse, magnetron sputtering technology, applied in the direction of sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problems of low deposition rate, limit popularization and application, restrict development, etc., and achieve deposition Effects of rate increase, plasma density increase, and interface performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

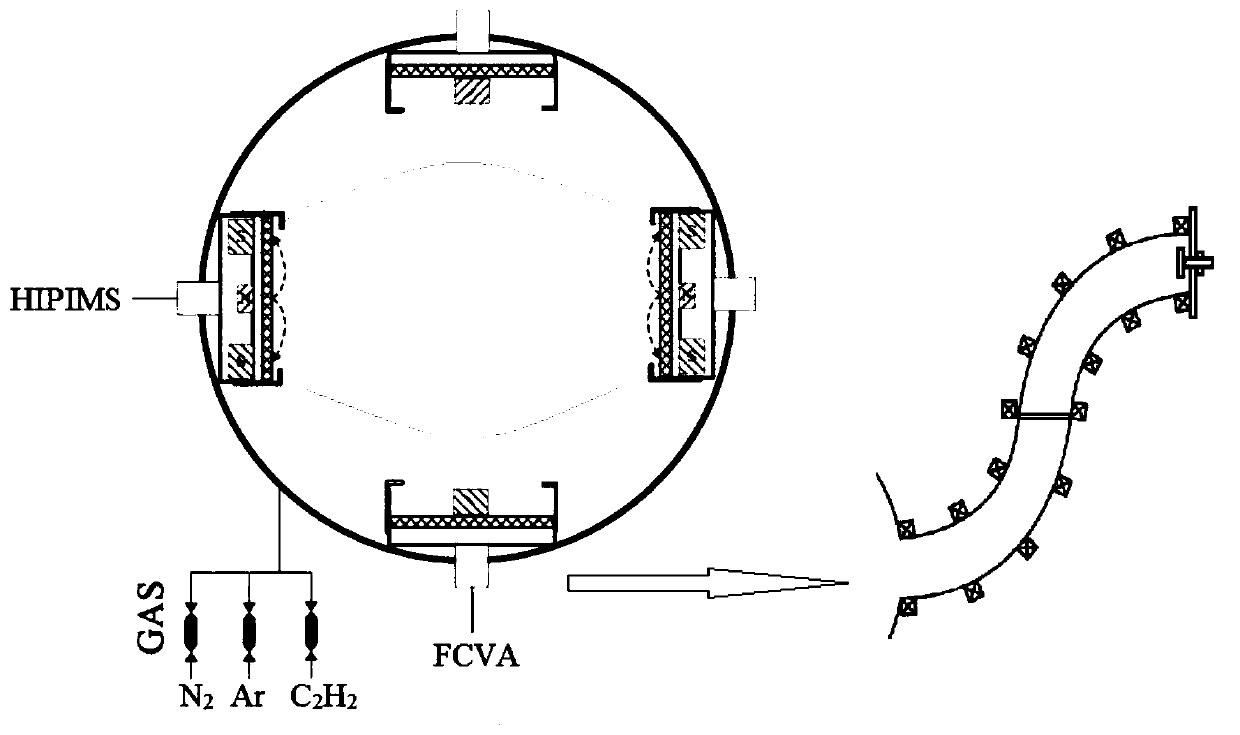

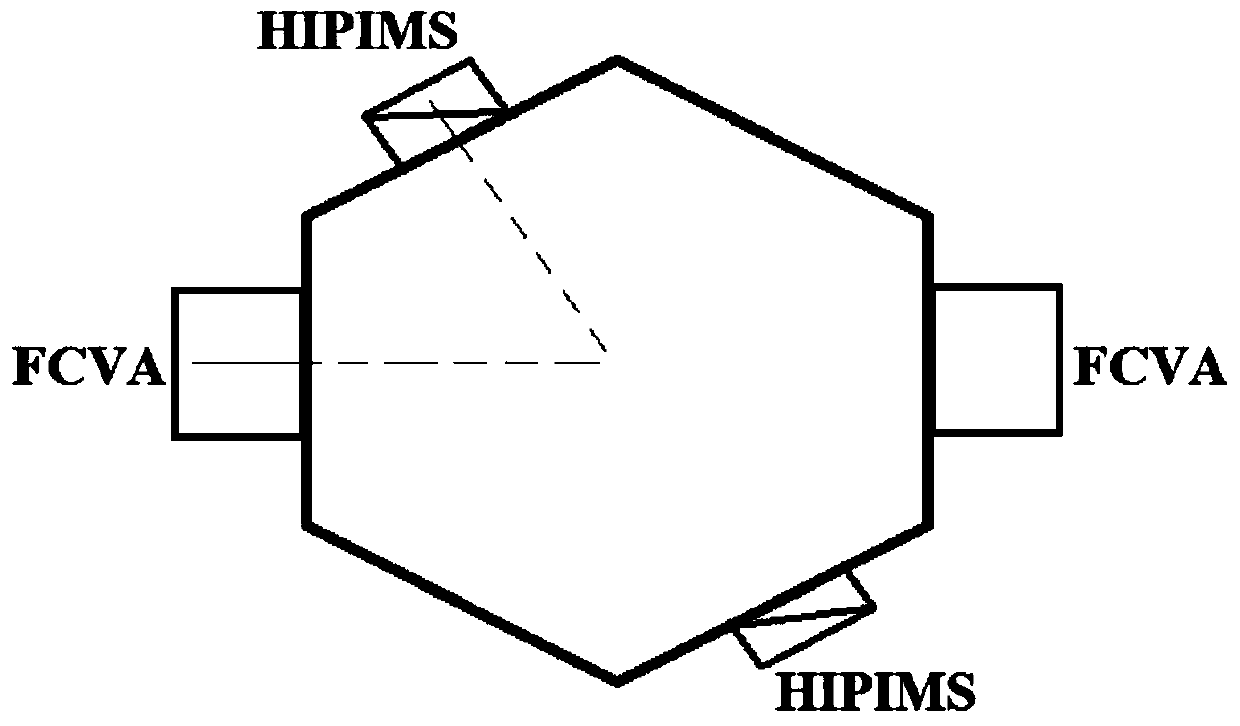

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 and figure 2 Shown, the specific embodiment of the present invention comprises substrate, and interconnected vacuum system, high-power pulse magnetron sputtering system, vacuum cathodic arc deposition system and control system, substrate passes high-power pulse magnetron sputtering system and vacuum The cathode arc deposition system is combined to prepare toner cartridges;

[0030] A method for preparing a toner cartridge combined with high-power pulsed magnetron sputtering technology, the method steps are as follows:

[0031] S01. Use heavy metal and gas mixed plasma to clean the surface of the substrate alternately with high and low energy;

[0032] S02. Utilize the high-power pulsed magnetron sputtering system (HIPIMS) to carry out secondary cleaning to the substrate;

[0033] S03. Vacuum cathodic arc deposition system (FCVA) u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com