A kind of smoke-suppressing benzoxazine resin composition and preparation method

A technology of resin composition and benzoxazine, which is applied in the field of high molecular polymer composition, can solve the problems of adverse effects on product performance, reduction of product mechanical performance, high addition of synergist, etc., and achieve good smoke suppression effect, reduce Smoke density, convenient and uniform dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

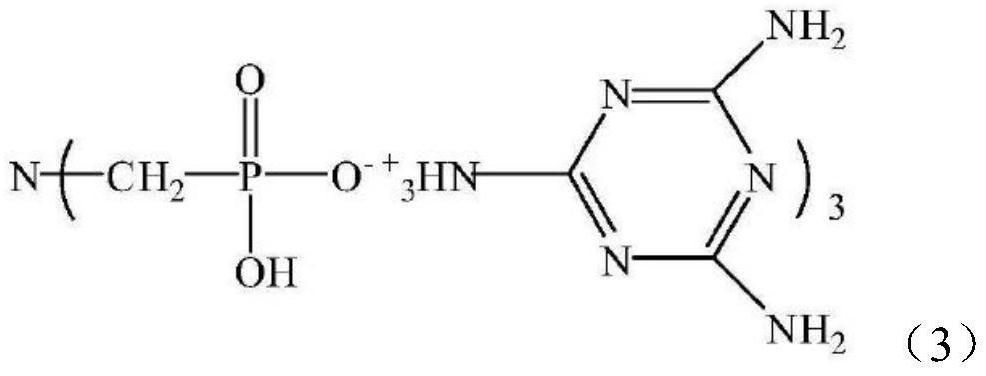

[0077] Embodiments 1-3: Preparation of smoke suppressant (C), in which crystallization aids were added in Examples 1 and 2, and crystallization aids were not added in Example 3.

[0078] Example 1:

[0079] Put 88.2g of 1,3,5-triazine-2,4,6-triamine into a reaction kettle with a stirring device, add 3000ml of deionized water, raise the temperature to 65°C and stir to obtain complete dissolution 1,3,5-triazine-2,4,6-triamine solution, and then 58.8g of amino trimethylene phosphoric acid was dissolved in deionized water, and gradually added dropwise to the reaction kettle, while adding 1.8g of ten Sodium dialkyl sulfonate was kept for 4 hours, filtered, washed and dried to obtain a white solid powder.

[0080] Product particle size (μm) distribution: D 10 :51.472;D 50 :62.713;D 90 : 79.826.

Embodiment 2

[0082] Put 50.4g of 1,3,5-triazine-2,4,6-triamine into a reaction kettle with a stirring device, add 2500ml of deionized water, raise the temperature to 75°C and stir to obtain complete dissolution 1,3,5-triazine-2,4,6-triamine solution, and then 44.1g of aminotrimethylene phosphoric acid was dissolved in deionized water, and gradually added dropwise to the reactor, while adding 2.2g of poly Sodium acrylate, keep warm for 5h, filter, wash and dry to obtain white solid powder.

[0083] Product particle size (μm) distribution: D 10 :56.365;D 50 :65.356;D 90 :73.423;

Embodiment 3

[0085] Put 88.2g of 1,3,5-triazine-2,4,6-triamine into a reaction kettle with a stirring device, add 3000ml of deionized water, raise the temperature to 65°C and stir to obtain complete dissolution 1,3,5-triazine-2,4,6-triamine solution, and then 58.8g of aminotrimethylene phosphoric acid was dissolved in deionized water, and gradually added dropwise to the reaction kettle, kept for 4h, filtered and washed , and dried to obtain a white solid powder.

[0086] Product particle size (μm) distribution: D 10 : 35.582;D 50 :67.633;D 90 :89.145;.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com