Highly anti-coagulant polystyrene microsphere and preparation and application methods thereof

A polystyrene microsphere, high-resistance technology, used in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve problems such as poor blood coagulation, achieve excellent blood compatibility, strong anticoagulation performance, Easy to operate and achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Another aspect of the embodiments of the present invention also provides a method for preparing high anticoagulation polystyrene microspheres, which includes:

[0031] In a protective atmosphere, the homogeneously mixed reaction system comprising alkene acid monomers, sodium sulfonate monomers, crosslinking agent monomers, initiators and water is polymerized and crosslinked at 50-100°C for 4-24 hours to obtain Active heparin aqueous solution;

[0032] The polystyrene microsphere body is contacted with the active heparin aqueous solution, and then the obtained polystyrene microsphere is placed in an acidic condition and heated at 45-80°C for 6-24 hours to obtain high anticoagulation through self-polymerization and cross-linking type polystyrene microspheres.

[0033] In some preferred embodiments, the preparation method specifically includes: adding alkenoic acid monomers, sodium sulfonate monomers, and crosslinking agent monomers to deionized water, and then stirring i...

Embodiment example

[0035] Wherein, as a more preferred embodiment of the present invention, the preparation method includes the following steps:

[0036] S1: Add a certain amount of alkene acid monomers, sodium sulfonate monomers, and crosslinking agent monomers to 100 parts by mass of deionized water, and then stir for no less than 30 minutes in a nitrogen or argon atmosphere to eliminate oxygen;

[0037] S2: Add a certain amount of initiator, keep stirring in nitrogen or argon atmosphere, and raise the temperature to 50-100°C, and react for 4-24 hours to obtain an aqueous solution of active heparin;

[0038] S3: After the obtained active heparin aqueous solution is cooled to room temperature, a quantitative amount of polystyrene microspheres is added to the solution and soaked for 0.15-2 hours;

[0039] S4, transfer the polystyrene microspheres into an acidic aqueous solution with a pH value of 0-4, heat at 45-80°C for 6-24 hours, then wash with deionization and then dry to obtain the high an...

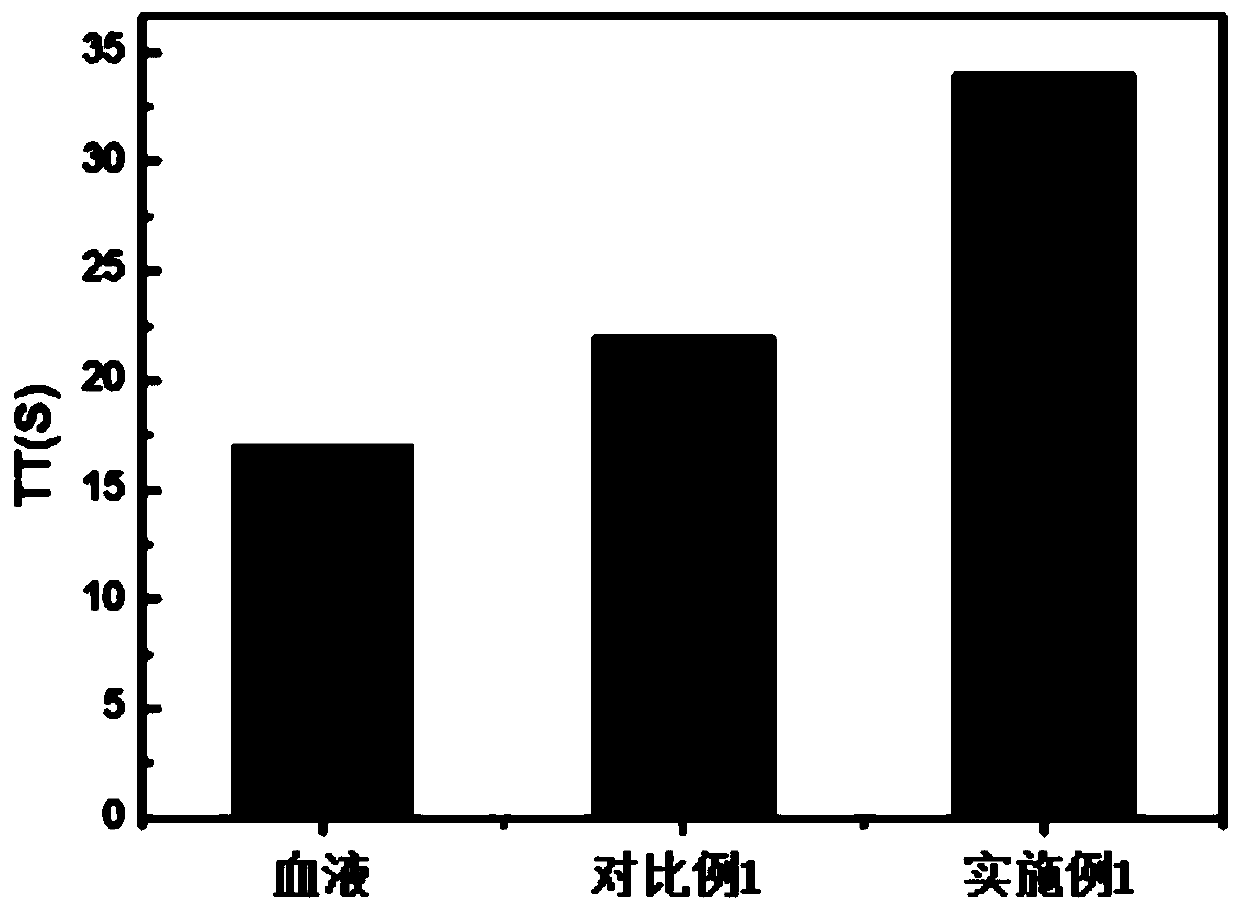

Embodiment 1

[0061] Step (1) Add 100g of deionized water into a three-necked flask, then add 3g of acrylic acid, 4g of sodium p-styrene sulfonate and 5g of N-methylolacrylamide, and then stir for 40min under a nitrogen atmosphere at 250 rpm , to get rid of the oxygen in the reaction solution;

[0062] Step (2) Add 0.2 g of azobisisobutylamidine hydrochloride, keep stirring in a nitrogen atmosphere, and raise the temperature to 80° C., and react for 10 hours to obtain an aqueous solution of active heparin;

[0063] Step (3) Weigh 20 g of polystyrene microspheres (commercially purchased product described in Comparative Example 1), and ultrasonically clean them with 20% ethanol / deionized solution for 20 minutes. Then, after the heparinoid aqueous solution obtained in step (2) is cooled to room temperature, the washed polystyrene microspheres are added to the solution and soaked for 1 hour;

[0064] Step (4) Transfer the polystyrene microspheres to an acidic aqueous solution with a pH value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com