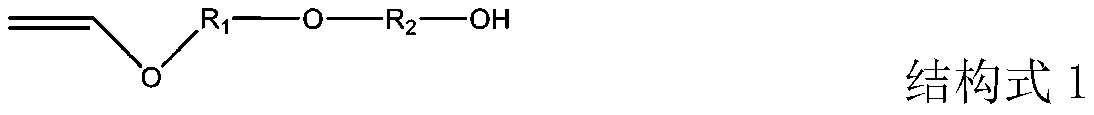

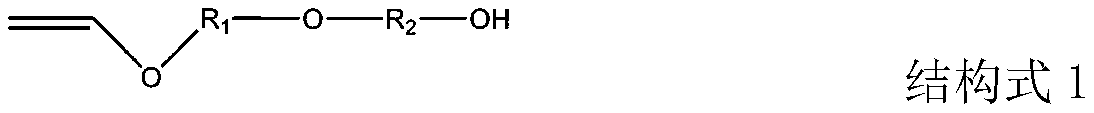

Short side chain anti-sludge polycarboxylic acid water reducer and preparation method thereof

A clay-resistant, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of increasing the adsorption of clay minerals, decreasing the water-reducing ability, and requiring separation and purification, so as to ensure the water-reduction rate, improve the tolerance, and make up for the The effect of reducing the steric repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 100 parts of 4-hydroxybutyl vinyl ether, 60 parts of fumaric acid, 60 parts of monomethyl maleate and 20 parts of acryloyl ethyl sulfobetaine and some deionized water into the reaction vessel, Stir well at 30°C. Start to add 2 parts of hydrogen peroxide, 0.5 parts of L-ascorbic acid and 0.5 parts of thioglycolic acid solution dropwise at a constant speed for 3 hours. After the dropwise addition, add NaOH solution to adjust the pH to 5, add some deionized water to adjust the solid content of the reaction solution to 40%, and obtain the anti-mud type mother liquid UC-CT1.

[0044] The preparation method of the maleic acid monomethyl ester is as follows: add anhydrous maleic diol in the reaction vessel, wait for the temperature to rise to 50-60°C, add maleic anhydride to react for 3 hours, and distill the reaction product under reduced pressure Remove the unreacted alcohol to obtain monomethyl maleate; wherein the ratio of maleic anhydride to maleic diol is 1:1.2.

Embodiment 2

[0046] Add 100 parts of ethylene glycol butyl vinyl ether, 75 parts of maleic anhydride, 52 parts of monobutyl maleate and 25 parts of acryloyl ethyl sulfobetaine and some deionized water into the reaction vessel, Stir well at 40°C. Start to add 2 parts of ammonium persulfate, L-ascorbic acid and mercaptopropionic acid solution dropwise at a constant speed, and the dropping time is 2.5 hours. After the dropwise addition, add some NaOH solution to adjust the pH to 5.5, add some deionized water to adjust the solid content of the reaction solution to 40%, and obtain the mud-resistant mother solution UC-CT2.

[0047] The preparation method of the monobutyl maleate is as follows: add anhydrous maleic diol in the reaction vessel, wait for the temperature to rise to 50-60° C., add maleic anhydride to react for 3 hours, and distill the reaction product under reduced pressure The unreacted alcohol is removed to obtain monobutyl maleate; wherein the ratio of maleic anhydride to maleic ...

Embodiment 3

[0049] Add 100 parts of diethylene glycol monovinyl ether, 90 parts of itaconic acid, 45 parts of monoethyl itaconate and 30 parts of methacryloyl ethyl sulfobetaine and some deionized water into the reaction vessel, Stir well at 40°C. Start to add ammonium persulfate, mohr's salt and thioglycolic acid solution dropwise at a constant speed, and the dropping time is 2h. After the dropwise addition is completed, add some NaOH solution to adjust the pH to 6, add some deionized water to adjust the solid content of the reaction solution to 40%, and obtain the mud-resistant mother solution UC-CT3.

[0050] The preparation process of the monoethyl itaconate is: itaconic acid, anhydrous C 1-4 Alcohol and benzoyl chloride are added to the reaction vessel and mixed, heated and stirred to a temperature of 70°C, and the reaction is continued for 3 hours, and the reaction product is distilled off under reduced pressure to remove excess C 1-4 Alcohol, then add the recrystallization solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com