Brazing method for ceramic and metal

A brazing method and ceramic technology, applied in the field of brazing of ceramics and metals, can solve the problems of difficulty in forming connections between ceramics and metal materials, affecting the strength and air tightness of joints, and large differences in thermal expansion coefficients, and improving production and distribution. , The effect of reducing thermal deformation and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

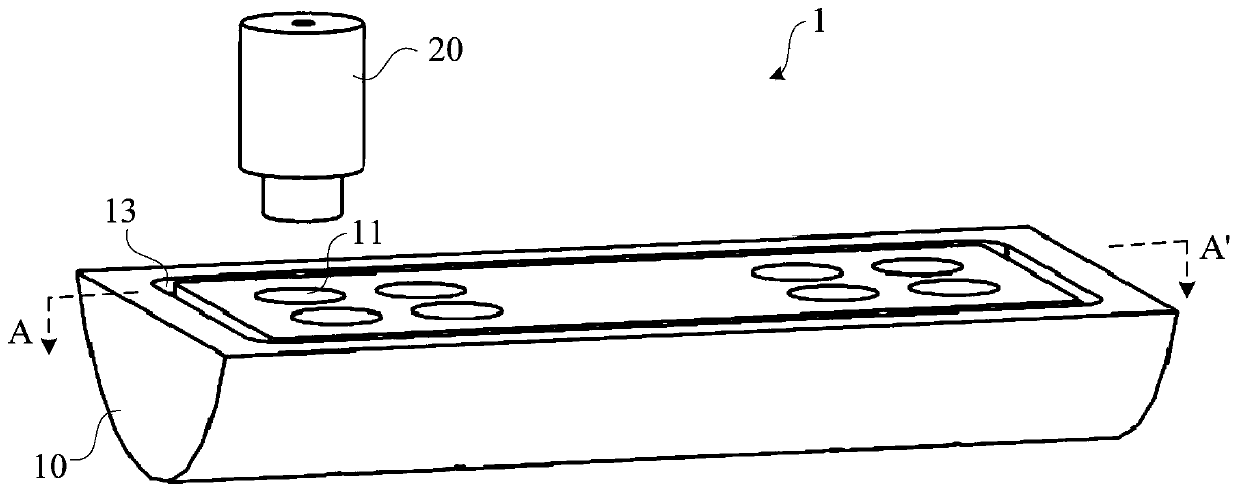

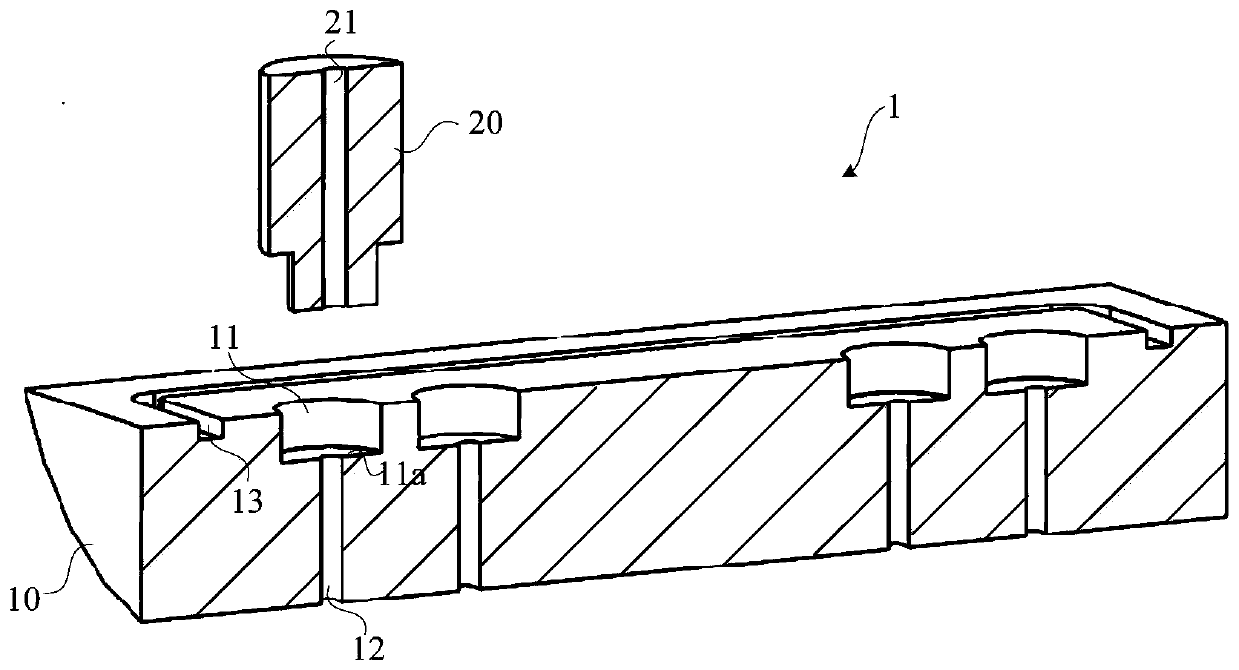

[0021] Hereinafter, preferred embodiments of the present disclosure will be described in detail with reference to the drawings. In the following description, the same reference numerals are given to the same components, and repeated descriptions are omitted. In addition, the drawings are only schematic diagrams, and the ratio of dimensions between components, the shape of components, and the like may be different from the actual ones.

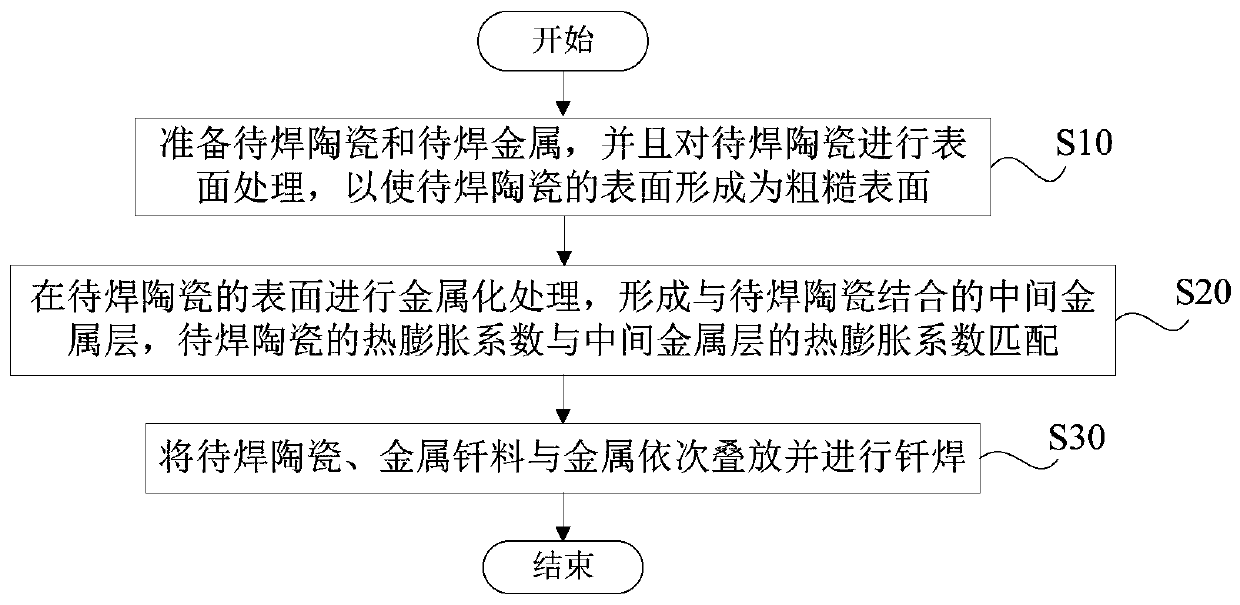

[0022] figure 1 A schematic flowchart of a ceramic-metal brazing method according to an embodiment of the present invention is shown.

[0023] The brazing method of ceramics and metal involved in the present embodiment includes: preparing ceramics 31 to be welded and metal 33 to be welded, and carrying out surface treatment on ceramics 31 to be welded, so that the surface of ceramics to be welded 31 is formed into a smooth surface (step S10 ); metallization is carried out on the surface of the ceramics to be welded 31 to form an intermediate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com