A kind of pet laser composite film and preparation method thereof for film laminating mother film

A technology of composite film and laser film, which is applied in the direction of coating and ink transfer from the original, can solve the problems of laser coating peeling off, small use limitation, winding dead wrinkles, etc., so as to increase the number of repeated use and promote Application range, avoid the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

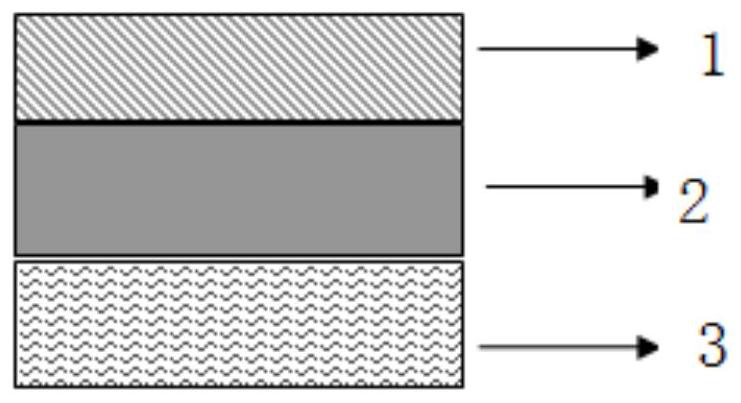

[0025] A kind of PET laser composite film that is used for film-pressed mother film of the present embodiment, as figure 1 As shown, it includes PET film 1, coating coating 2, and laser film lamination 3 laminated in sequence.

[0026] The preparation method of this PET laser composite film comprises the following steps:

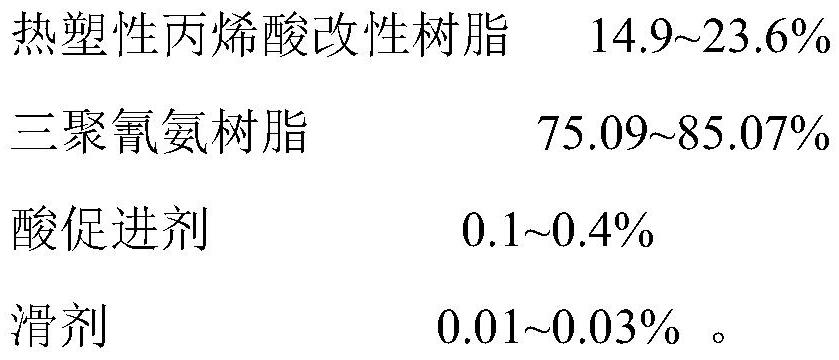

[0027] Step 1, preparation of coating coating: take respectively 14.9% thermoplastic acrylic modified resin, 85.07% melamine resin, 0.1% acid accelerator and 0.03% slip agent, the thermoplastic acrylic modified resin, terpolymer Cyanamide resin, acid accelerator and slip agent are mixed and stirred evenly to obtain coating paint, which is ready for use;

[0028] Step 2, coating coating: using a PET film, coating the coating coating prepared above on the PET film, drying the coating coating to obtain a coating coating;

[0029] Step 3, laser film pressing: laser film pressing is carried out on the above-mentioned coating layer to obtain a laser film laminat...

Embodiment 2

[0032] A kind of PET laser composite film that is used for film-pressed mother film of the present embodiment, as figure 1 As shown, it includes PET film 1, coating coating 2, and laser film lamination 3 laminated in sequence.

[0033] The preparation method of this PET laser composite film comprises the following steps:

[0034] Step 1, preparation of coating coating: take respectively 23.6% thermoplastic acrylic modified resin, 75.09% melamine resin, 0.4% acid accelerator and 0.01% slip agent, the thermoplastic acrylic modified resin, terpolymer Cyanamide resin, acid accelerator and slip agent are mixed and stirred evenly to obtain coating paint, which is ready for use;

[0035] Step 2, coating coating: using a PET film, coating the coating coating prepared above on the PET film, drying the coating coating to obtain a coating coating;

[0036] Step 3, laser film pressing: laser film pressing is carried out on the above-mentioned coating layer to obtain a laser film laminat...

Embodiment 3

[0039] A kind of PET laser composite film that is used for film-pressed mother film of the present embodiment, as figure 1 As shown, it includes PET film 1, coating coating 2, and laser film lamination 3 laminated in sequence.

[0040] The preparation method of this PET laser composite film comprises the following steps:

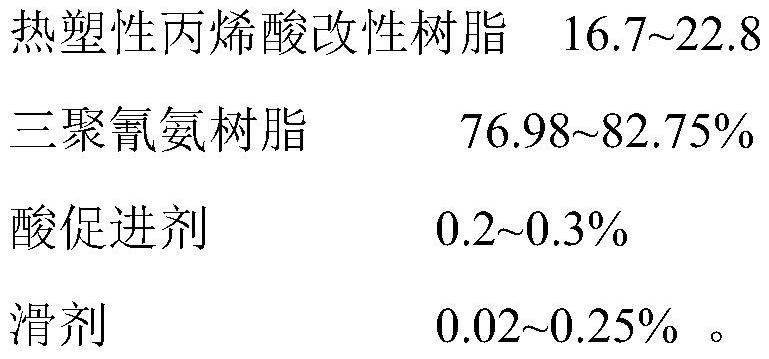

[0041] Step 1, prepare coating paint: take respectively 20.8% thermoplastic acrylic modified resin, 78.07% melamine resin, 0.2% acid accelerator and 0.03% slip agent, the thermoplastic acrylic modified resin, terpolymer Cyanamide resin, acid accelerator and slip agent are mixed and stirred evenly to obtain coating paint, which is ready for use;

[0042] Step 2, coating coating: using a PET film, coating the coating coating prepared above on the PET film, drying the coating coating to obtain a coating coating;

[0043] Step 3, laser film pressing: laser film pressing is carried out on the above-mentioned coating layer to obtain a laser film lamination, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com