Ship steel scrap recycling cutting system

A cutting system and scrap steel technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing, etc., can solve the problems of short effective working time, more preparation work, and low per capita output, so as to reduce invalid labor and save Time, the effect of increasing the output per capita

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

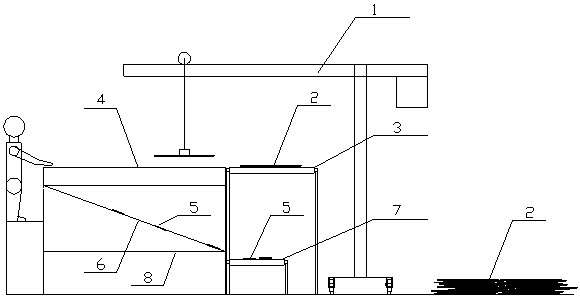

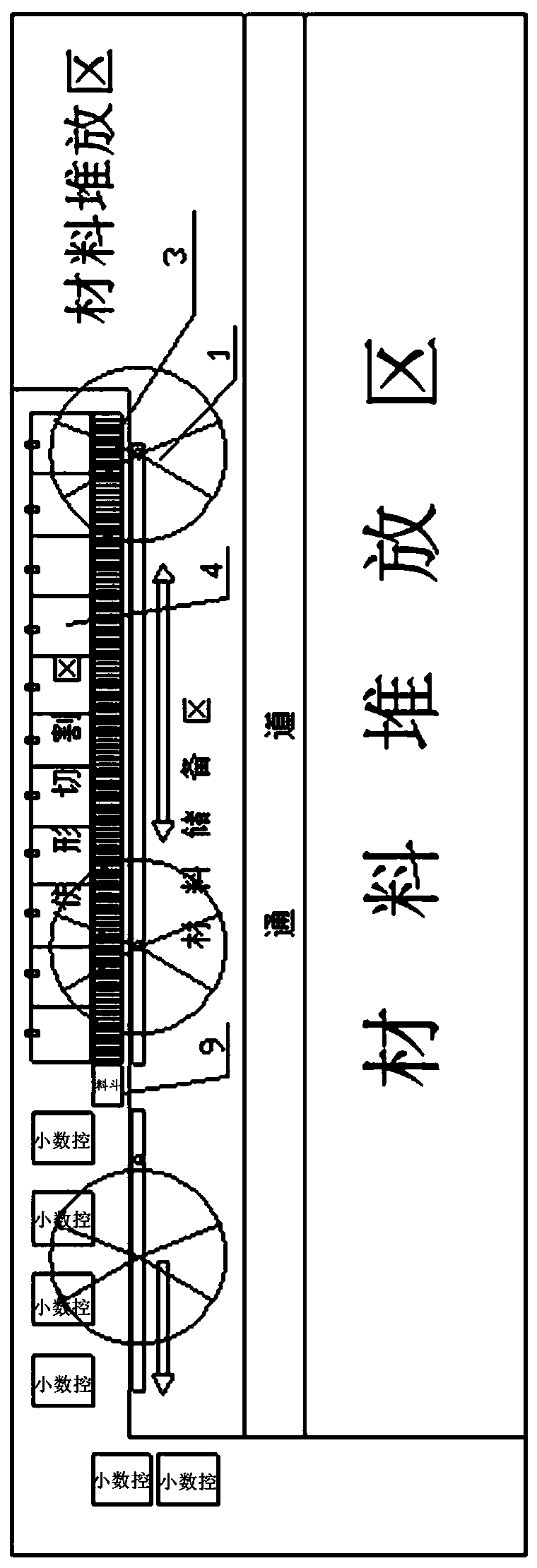

[0021] Such as figure 1 , figure 2 A ship scrap recycling cutting system is shown, including

[0022] A conveying assembly, the conveying assembly includes an upper conveying roller table 3 distributed up and down, a lower conveying roller table 7, a hopper 9 is also arranged at the discharge end of the lower conveying roller table 7, and the upper conveying roller table 3 is conveyed by an upper conveying roller table The motor drive works, and the lower floor conveyor roller table 7 is driven by the lower floor conveyor motor to work.

[0023] A cutting assembly, the cutting assembly includes a cutting platform 4 arranged on the side of the upper conveying roller table 3, and the height of the cutting platform 4 is substantially flush with the height of the upper conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com