Strength-increasing shield tunneling machine cutter ring machining process

A technology of increasing strength and processing technology, which is applied in the field of shield machine cutter ring processing technology for increasing strength, can solve problems such as easy deformation, and achieve the effects of increasing pressure, reducing contact area, and facilitating stamping and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

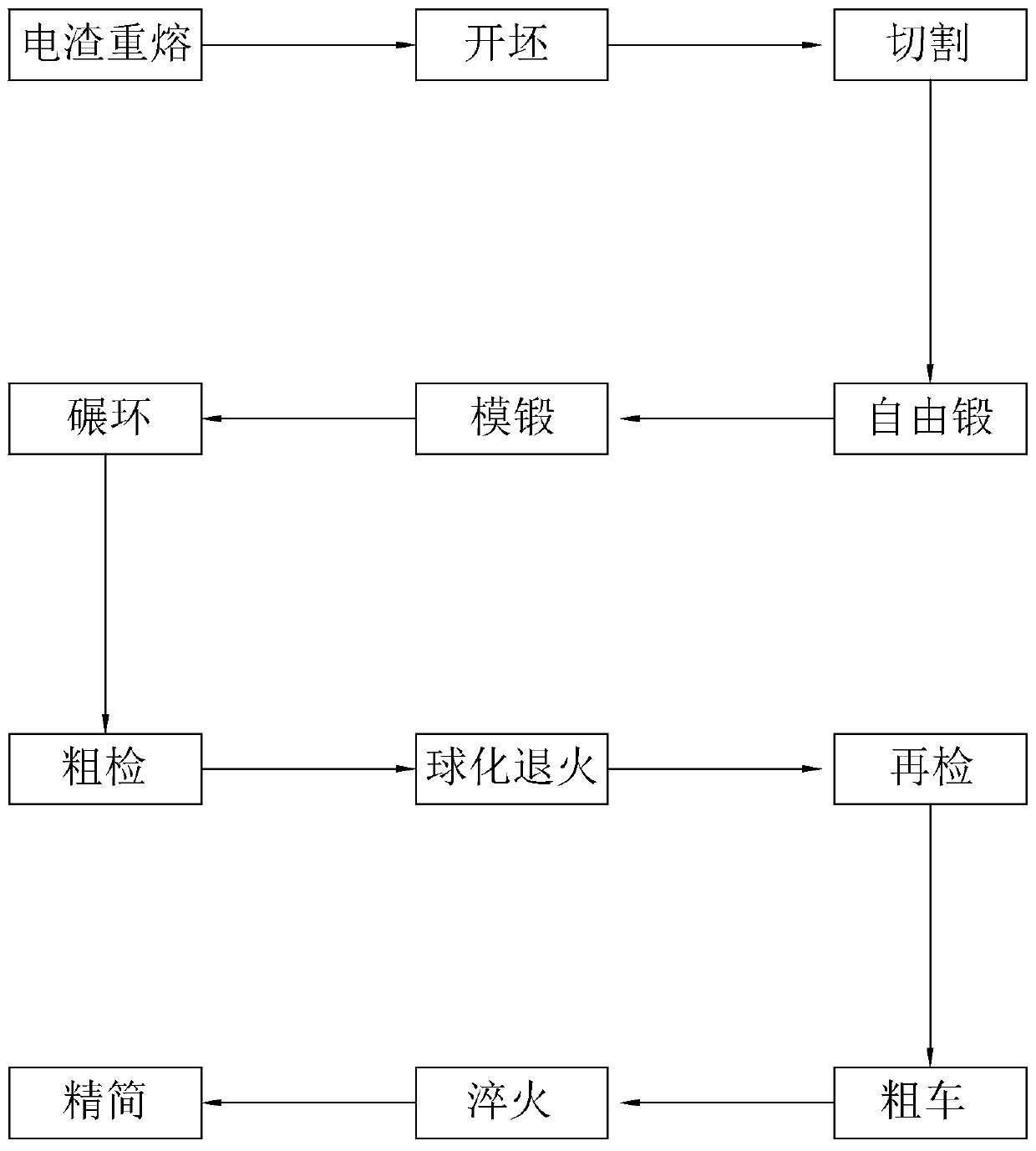

[0035] Embodiment 1: A kind of shield machine cutter ring processing technology that increases strength, such as figure 1 shown, including the following steps:

[0036] Step S1: electroslag remelting, placing the steel ingot in an electroslag furnace for remelting, so that the electroslag is remelted into an electroslag ingot. The electroslag remelted steel has high purity, low sulfur content, less non-metallic inclusions, smooth surface of steel ingot, clean uniform and dense, uniform metallographic structure and chemical composition, so the material structure strength is higher.

[0037] Step S2: billet opening, forging the electroslag ingot with an electro-hydraulic hammer, heating the electroslag ingot to above 800°C before billet opening, and shaping it into a cylindrical bar under the impact of the electro-hydraulic hammer.

[0038] Step S3: Cutting, first annealing the original bar, using annealing to release the internal stress generated by blank forging, and reduce t...

Embodiment 2

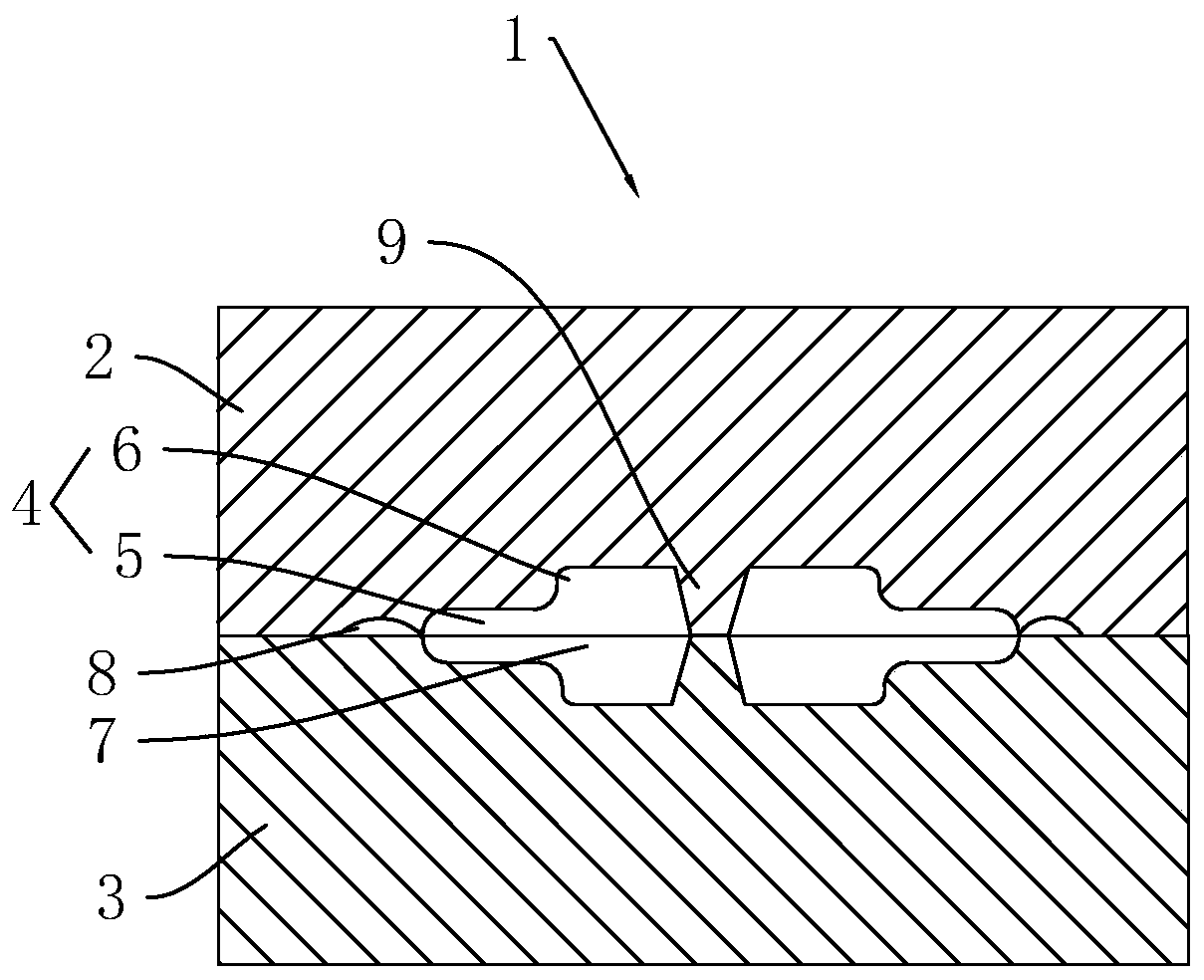

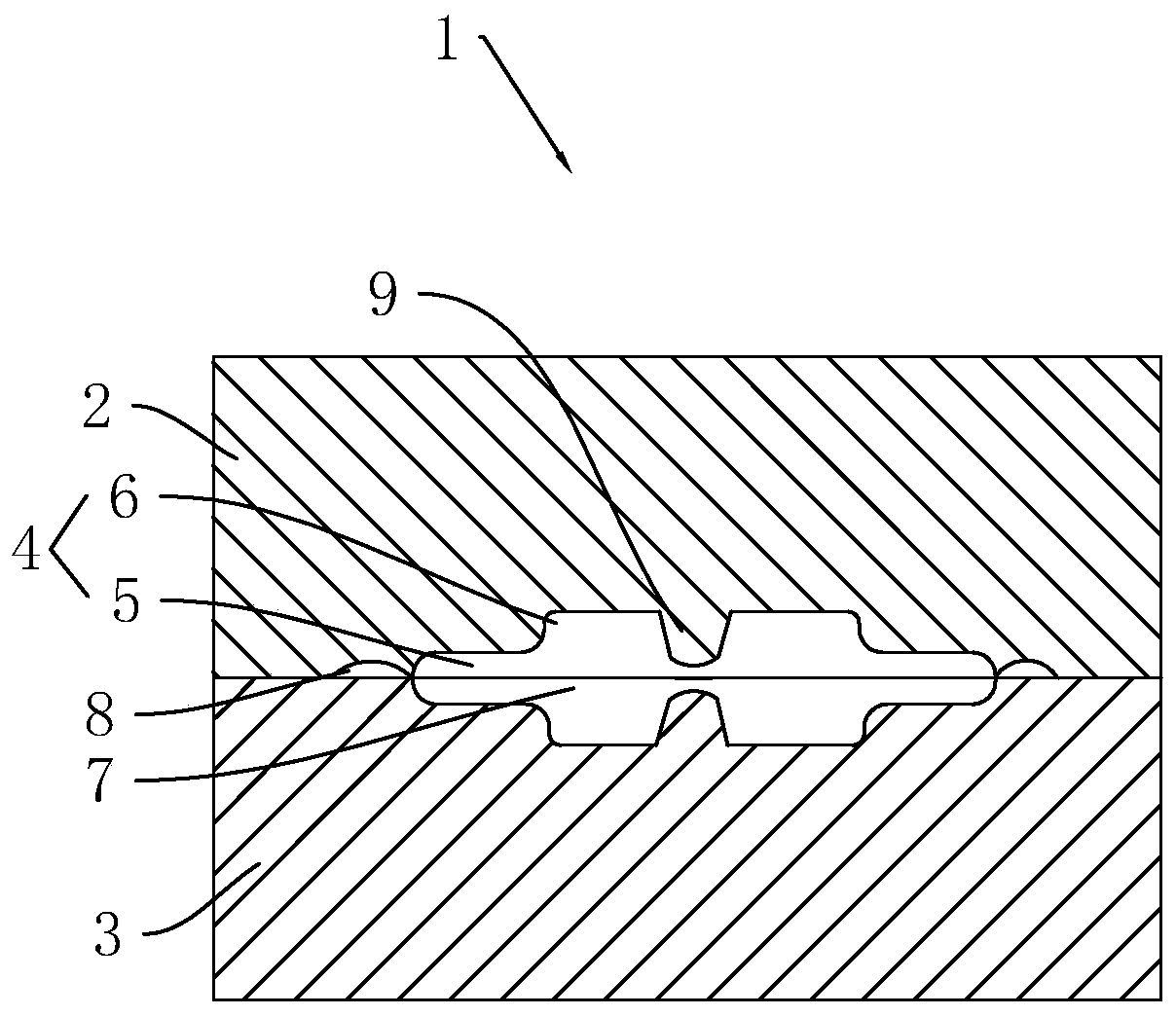

[0049] Embodiment 2: A kind of shield machine cutter ring processing technology that increases strength, such as image 3 As shown, the difference from Example 1 is that step S5: die forging, the rough blank after free forging is placed in the forging die 1, and the temperature of the rough blank is not cooled at this time, and the rough blank is forged and formed into The rough-formed billet has a central groove formed by forging and pressing at the center of the rough-formed billet, and the thickness of the outer ring is smaller than that near the center.

[0050] The die forging machine is a steam-air hammer. The forging die 1 includes an upper die 2 and a lower die 3 . A circular forging die groove 4 is provided on the lower surface of the upper die 2 and the upper surface of the lower die 3 . The forging die groove 4 includes a first ring groove 5 and a second ring groove 6, the first ring groove 5 and the second ring groove 6 are arranged coaxially and communicate with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com