Environmentally-friendly flame-retardant water-based inorganic coating for interior walls and preparation method of coating

A technology of interior wall paint and paint, applied in the field of paint, can solve problems such as shedding, mildew, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

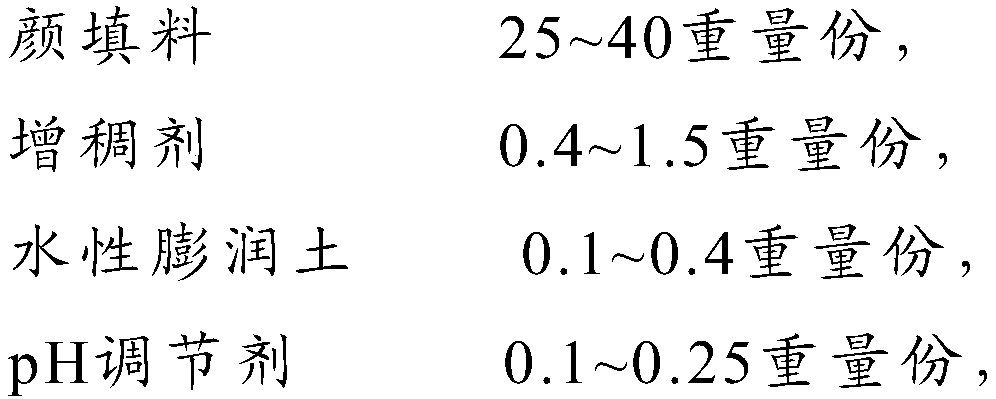

[0068] According to a preferred embodiment of the present invention, the coating comprises the following raw material components in weight ratio:

[0069] 10-40 parts by weight of water,

[0070] Silica sol 20~40 parts by weight,

[0071] Emulsion 4~6 parts by weight.

[0072] In a further preferred embodiment, the coating comprises the following raw material components in a weight ratio:

[0073] 15-35 parts by weight of water,

[0074] Silica sol 22~32 parts by weight,

[0075] Emulsion 3-5 parts by weight.

[0076] Wherein, in the present invention, the silica sol is used as the main film-former, and the emulsion is the auxiliary film-former to increase the flexibility of the coating. Wherein, since the volume shrinkage of silica sol is relatively large in the film-forming process, cracks are prone to occur, and in the present invention, the emulsion is added to modify the silica sol, so that the emulsion is filled in the gaps of the Si-O-Si network structure of the sili...

Embodiment 1

[0203] The preparation of embodiment 1 diatomaceous earth compound

[0204] Take 15mL of tetrabutyl titanate, 75mL of absolute ethanol, 7.5mL of distilled water and 1.5mL of acetic acid, stir and mix tetrabutyl titanate and absolute ethanol, then add acetic acid dropwise, and then slowly add distilled water dropwise to form TiO 2 Precursor gel, prepare multiple copies and store them for later use;

[0205] Weigh 30 g of diatomite powder, 0.8 g of graphene, and the TiO prepared above 2 Precursor gel 5g, add an appropriate amount of water to the three, stir and mix well, put it in a high-pressure reactor, and react at 150°C for 12 hours under magnetic stirring to obtain a mixed solution;

[0206] The mixed solution was dried at 60°C and placed in a nitrogen atmosphere furnace, and kept at 650°C for 2 hours to obtain the diatomite composite.

Embodiment 2

[0207] The preparation of embodiment 2 diatomaceous earth compound

[0208] Take 6 mL of tetrabutyl titanate, 75 mL of absolute ethanol, 10 mL of distilled water and 5 mL of acetic acid, stir and mix tetrabutyl titanate and absolute ethanol, then add acetic acid dropwise, and then slowly add distilled water dropwise to form TiO 2 Precursor gel, preparation of multiple TiO 2 The precursor gel is placed for use;

[0209] Weigh 28g of diatomite powder, 0.8g of graphene, and the TiO prepared above 2 Precursor gel 3.5g, add an appropriate amount of water to the three, stir and mix well, put it in a high-pressure reactor, and react at 150°C for 12 hours under magnetic stirring to obtain a mixed solution;

[0210] The mixed solution was dried at 60°C and placed in a nitrogen atmosphere furnace, and kept at 650°C for 2 hours to obtain a diatomaceous earth compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com