Process method of heat insulation sample sample car sample

A process method and prototype technology, applied in the field of auto parts processing technology, can solve the problems of no cost saving, space saving, loss of timeliness, large economic burden, etc., to improve competitiveness, reduce mold input costs, and reduce production cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

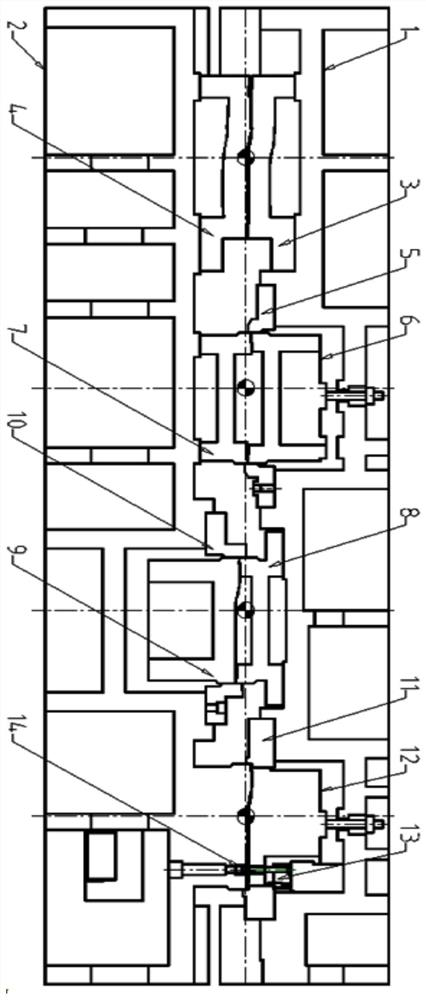

[0027] Embodiment 1: see figure 1 , in the prior art, the complete stamping process of the parts includes: forming, trimming and punching, flanging and hemming. from figure 1 It can be seen that the mold to be used includes an upper die base 1, a lower die base 2, an upper molding insert 3, a lower molding insert 4, an upper trimming insert 5, a first presser 6, a lower insert 7, a turning Edge insert 8, top piece 9, flange lower insert 10, edge wrapping upper insert 11, second presser 12, punching punch 13, punching die 14, etc.

[0028] In the prior art, when designing the upper mold base 1 and the lower mold base 2, it is necessary to consider the traditional positioning and connection fastening factors required to connect with the mold base. The plate groove is clamped and fixed with the machine tool.

[0029] The trimming of the traditional stamping process needs to fix the upper and lower trimming inserts after processing to the upper and lower mold bases 2 respective...

Embodiment 2

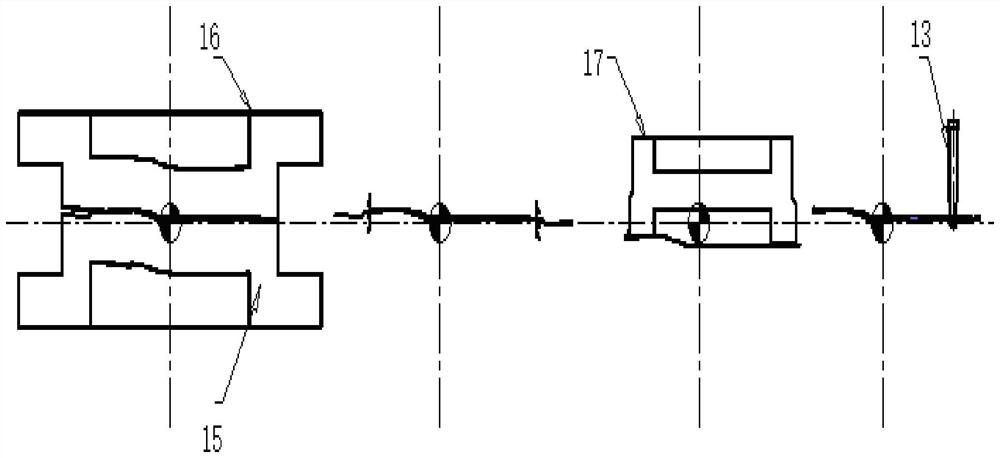

[0034] Embodiment 2: the process of the present invention see figure 2 A kind of heat insulation sample sample car sample processing method, comprising the following steps:

[0035] (1) Forming convex and concave molds and flanging convex molds 17 required for processing products according to product surface design;

[0036] Described forming male and female mold comprises forming male die 15 and forming female die 16, and both comprise the profile feature that product molding needs, and can keep the part that needs flanging when product flanging work;

[0037] The flanging punch 17 includes profile features required for product molding and contour features required for flanging;

[0038] (2) Forming convex and concave molds and flanging convex mold 17 are used for blanking of castings before making;

[0039] (3) Compile the numerical control program for processing forming convex and concave dies and flanging punches 17, compile the numerical control program for product tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com