Magnetic sheet based on amorphous or nanocrystalline strip material and preparation method thereof

A technology of nanocrystalline strips and magnetic sheets, which is applied in chemical instruments and methods, inductance/transformer/magnet manufacturing, lamination devices, etc. problems such as controlling the permeability range of the magnetic sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a method for preparing the above-mentioned magnetic flakes based on amorphous or nanocrystalline strips, comprising the following steps:

[0037] (1) heat-treating the amorphous or nanocrystalline ribbon;

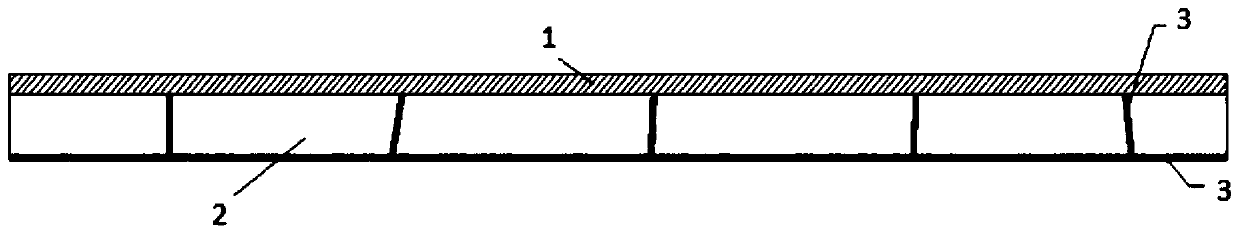

[0038] (2) laminating the bonding layer on the heat-treated amorphous or nanocrystalline strip in the step (1) to obtain a composite strip;

[0039] (3) crushing the composite strip into scales, and then sequentially performing spray oxidation treatment or hot water spray treatment to obtain an amorphous or nanocrystalline single-layer structure;

[0040] (4) Laminating the amorphous or nanocrystalline single-layer structure to obtain the magnetic flakes.

[0041] In the present invention, the amorphous or nanocrystalline ribbon is first heat-treated. In the present invention, when heat-treating the amorphous strip, the heat-treatment temperature is preferably 350-450°C, more preferably 380-440°C; the heat-treatment time is preferably...

Embodiment 1

[0051] (1) heat-treat the iron-based amorphous strip with a thickness of 25 μm±3 μm in a vacuum environment, the temperature of the heat treatment is 420° C., and the time is 2 hours;

[0052] (2) A layer of polyacrylic single-sided tape is laminated on the heat-treated amorphous strip, and the thickness of the tape is 3 μm;

[0053] (3) Use a circular pressure roller with a quadrangular pyramid texture on the surface to crush the side of the amorphous strip without the composite tape to obtain a scaly amorphous strip; wherein the crushing pressure is 6kg / cm 2 , the number of times is 1; the height of the square pyramid is 0.1mm, and the width is 0.1mm;

[0054] (4) Use water spray to carry out spray oxidation treatment to described scaly amorphous strip material, obtain composite strip material; Wherein the temperature of spray oxidation treatment is 40 ℃, time is 25min; After spray oxidation treatment, to described composite strip material washing and drying;

[0055] (5) ...

Embodiment 2

[0058] (1) The iron-based nanocrystalline strip with a thickness of 20 μm ± 3 μm is heat-treated under nitrogen protection, the temperature of the heat treatment is 550 ° C, and the time is 1.5 h;

[0059] (2) A layer of polyacrylic double-sided tape is laminated on the heat-treated nanocrystalline strip, and the thickness of the tape is 5 μm;

[0060] (3) use the circular pressure roller with quadrangular pyramid texture on the surface to crush the side of the nanocrystalline tape without the composite tape to obtain the scaly nanocrystalline tape; wherein the crushing pressure is 5kg / cm 3 , the number of times is 2 times; the height of the quadrangular pyramid is 1mm, the width is 2mm, and the length is 1.5mm;

[0061] (4) Using CO 2 Aqueous solution spray spray oxidation treatment on the said scaly nanocrystalline strips to obtain composite strips; wherein CO 2 The pH value of the aqueous solution is 5.6, the temperature of the spray oxidation treatment is 60° C., and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com