Tritium protection material and preparation method thereof

A protective material and mixing technology, applied in reactors, nuclear engineering, shielding and other directions, can solve the problems of increasing tritium permeation, increasing tritium permeation rate, unable to achieve tritium protection, etc. Improved radiation protection performance and significant effect of tritium protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the tritium protection material provided by the embodiment of the present invention combines the enhanced toughening performance of micro-nano inorganic substances and the radiation protection performance of micro-nano metal compounds containing metal elements such as lead and bismuth, and then adopts the method of physical blending. It is added to rubber latex, and then molded and vulcanized by dipping, coating and other methods.

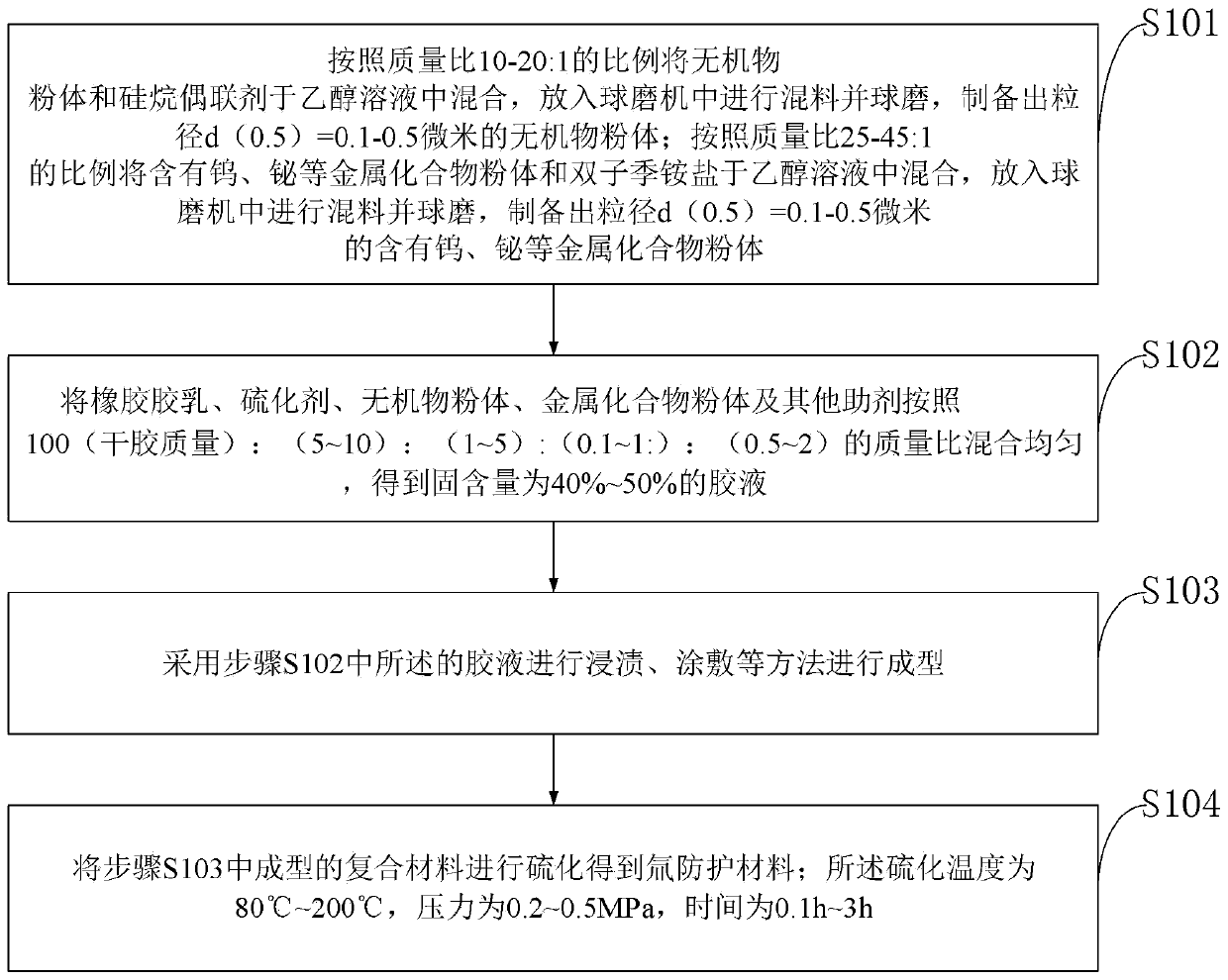

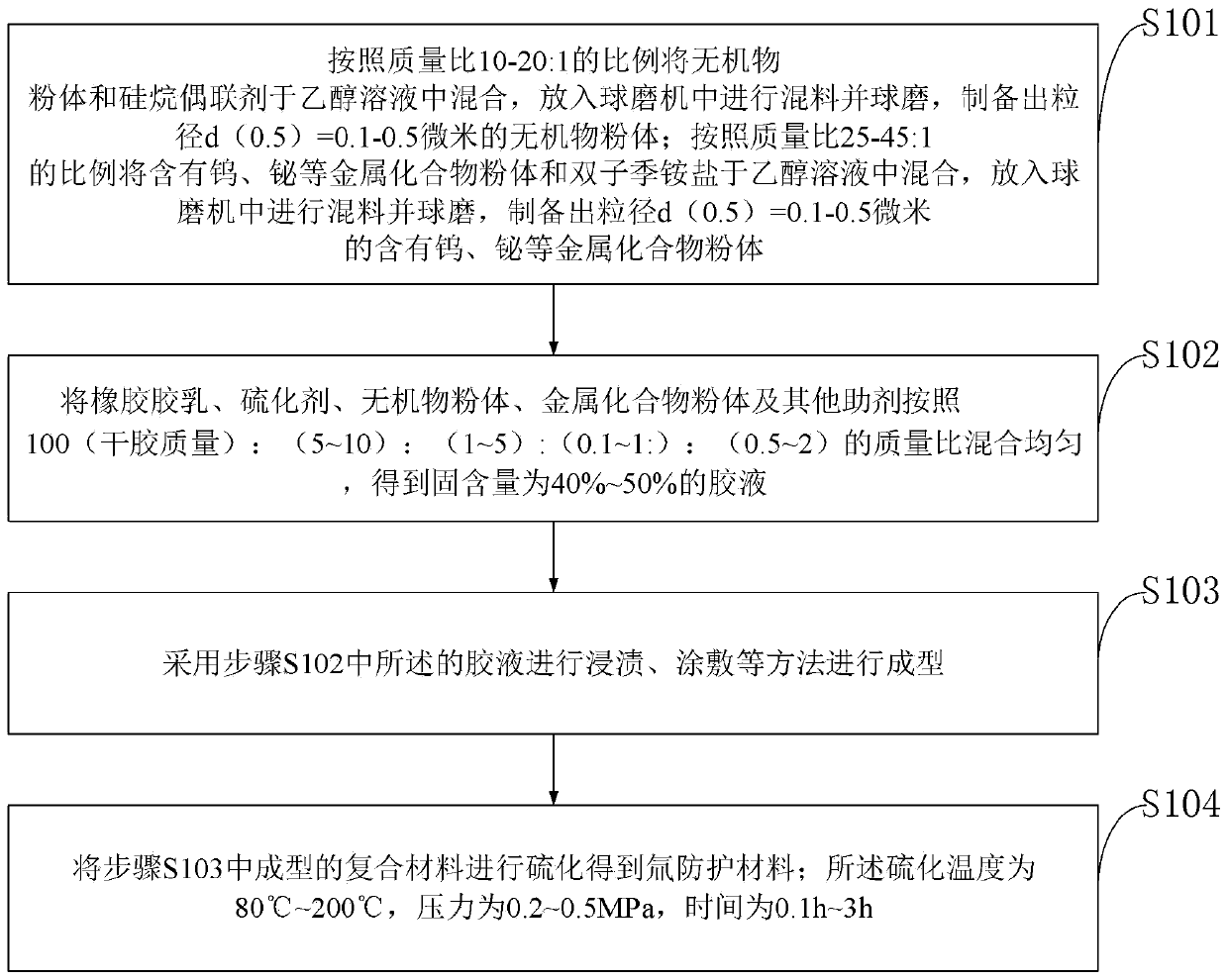

[0034] The preparation method of the tritium protection material provided by the embodiment of the present invention, the specific steps include:

[0035] S101: Mix the inorganic powder and the silane coupling agent in the ethanol solution according to the mass ratio of 10-20:1, put them into a ball mill for mixing and ball milling, and prepare the particle size d(0.5)=0.1-0.5 Micron inorganic powder; according to the mass ratio of 25-45:1, mix metal compound powder containing tungsten, bismuth and gemini quaternary...

Embodiment 1

[0045] Step 1. Mix montmorillonite and silane coupling agent in ethanol solution according to the mass ratio of 10:1, put them into a ball mill for mixing and ball milling, and prepare montmorillonite with particle size d(0.5)=0.2 microns Soil powder; mix bismuth tungstate powder and gemini quaternary ammonium salt in ethanol solution according to the mass ratio of 25:1, put them into a ball mill for mixing and ball milling, and prepare a particle size d(0.5)=0.1 Micron bismuth tungstate powder;

[0046] Step 2, the butyl rubber latex, vulcanizing agent, montmorillonite, bismuth tungstate powder and vulcanization accelerator stannous chloride are subjected to ultrasonication according to the mass ratio of 100 (dry rubber quality): 5:1:0.2:0.8 Disperse and mix evenly to obtain a glue solution with a solid content of 40% to 50%;

[0047] Step 3, adopting the glue solution described in step 2 to carry out the method of coating and forming into a diaphragm;

[0048] Step 4: Sulp...

Embodiment 2

[0050] Step 1. Mix silicon dioxide and silane coupling agent in ethanol solution according to the mass ratio of 15:1, put them into a ball mill for mixing and ball milling, and prepare a carbon dioxide with a particle size of d(0.5)=0.1 micron. Silicon powder; mix lead oxide powder and gemini quaternary ammonium salt in ethanol solution according to the mass ratio of 25:1, put them into a ball mill for mixing and ball milling, and prepare a particle size d(0.5)=0.1 micron lead oxide powder;

[0051] Step 2, bromobutyl rubber latex, vulcanizing agent, silicon dioxide, lead oxide powder and vulcanization accelerator stannous chloride are passed according to the mass ratio of 100 (dry rubber quality): 5:5:0.3:0.6 Ultrasonic dispersion to make it evenly mixed to obtain a glue with a solid content of 40% to 50%;

[0052] Step 3, adopting the method for impregnating the glue solution described in step 2 to form gloves;

[0053] Step 4: vulcanize the glove formed in Step 3 at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com