Consumable part fault detection method in plasma arc spray gun

A plasma arc and fault detection technology, which is applied in the direction of plasma, electrical components, and measuring electronics, can solve the problems of unfavorable fault characteristic signal acquisition, practical difficulties, detection and protection allergies, etc., and achieve stable and reliable detection results and strong anti-interference ability , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

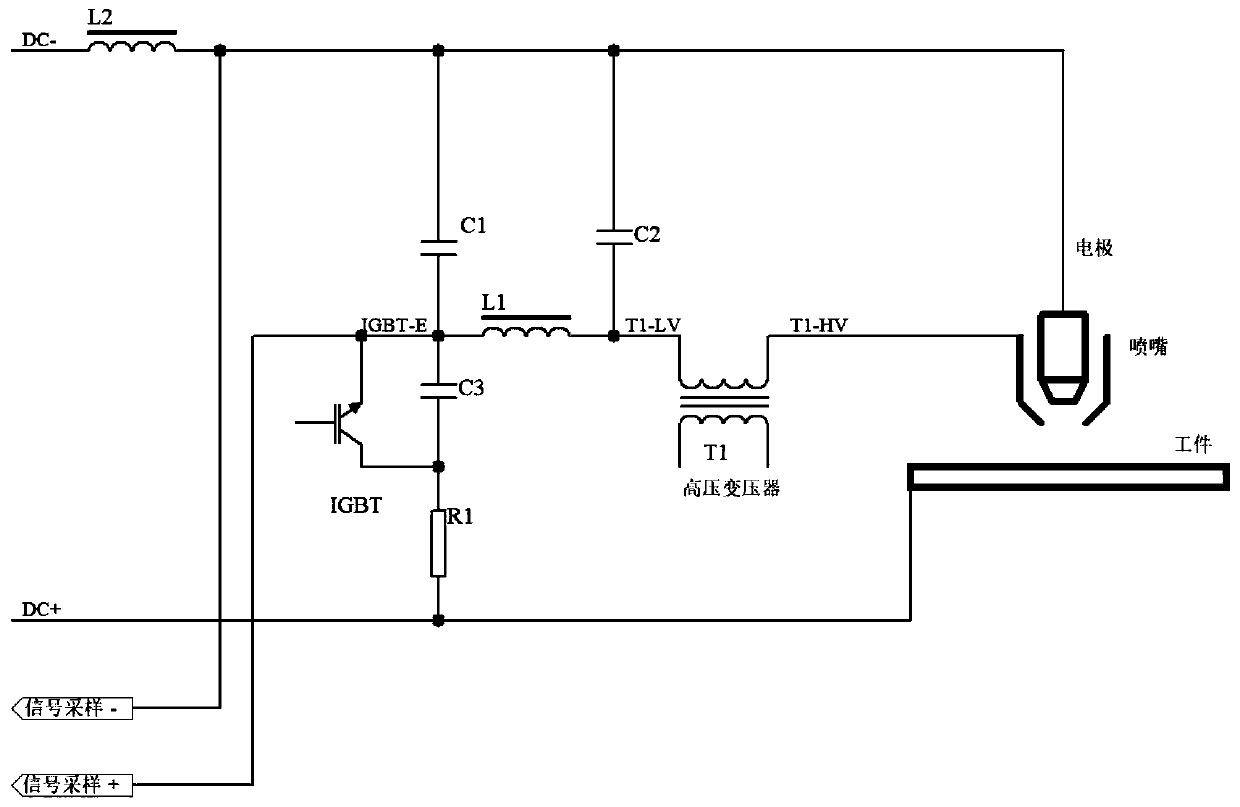

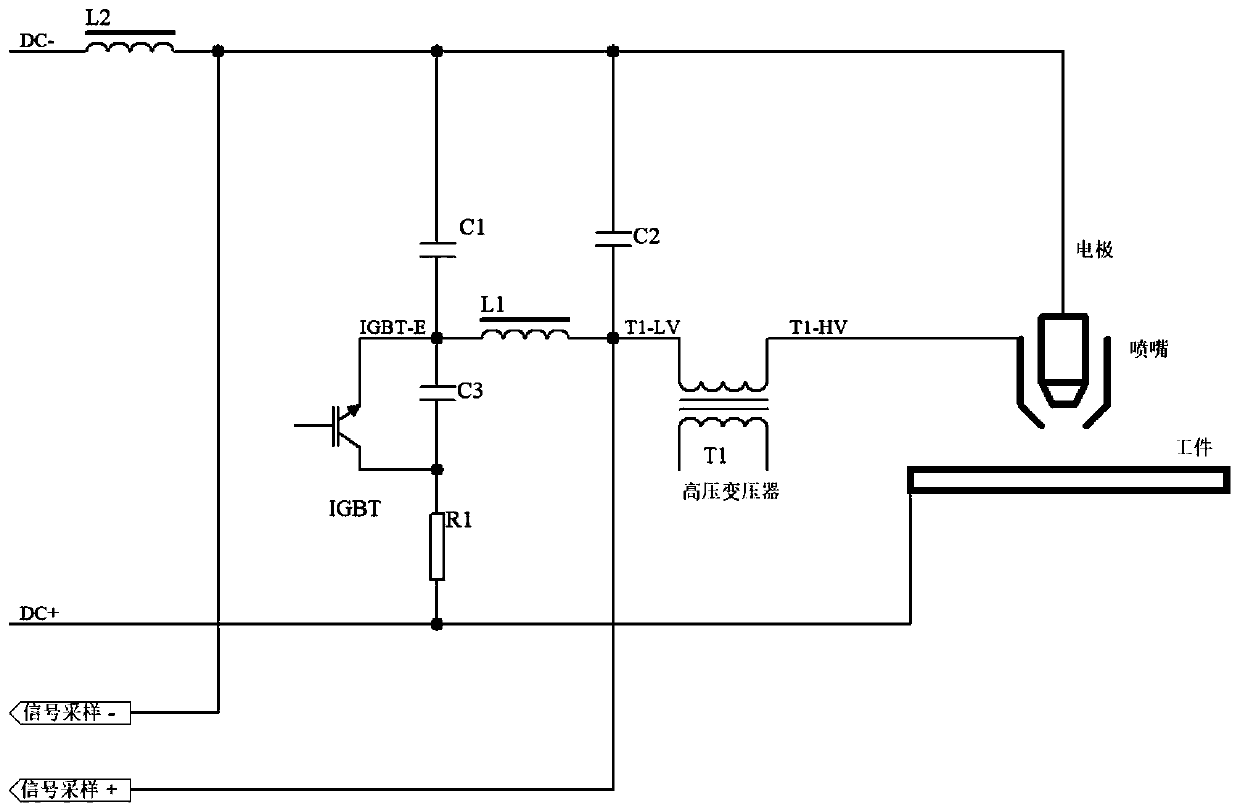

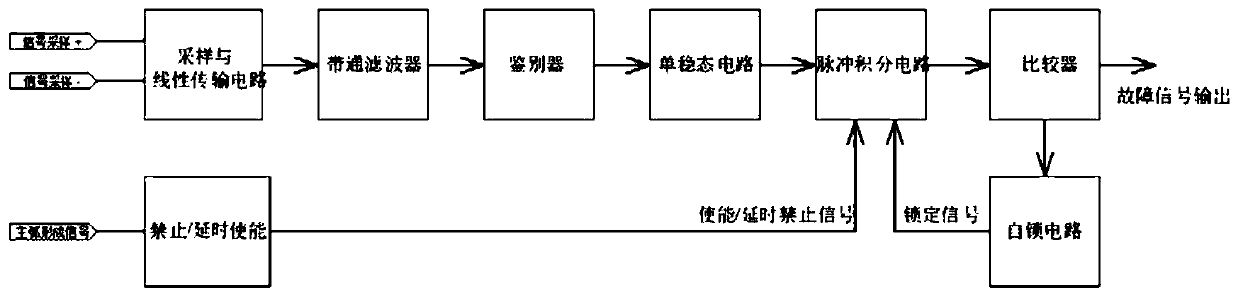

[0032] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0033] Such as figure 1 and figure 2 As shown, a method for detecting faults of consumable parts in a plasma arc spray gun of the present invention, the method includes: during the operation of the plasma arc spray gun, continuously detect the E pole voltage (IGBT-E) of the arc-turning IGBT and the high-voltage arc ignition transformer At least one of the low-voltage terminal voltages (T1-LV);

[0034] Determining at least one of the E pole voltage of the arc-turning IGBT and the low-voltage terminal voltage of the high-voltage arc-igniting transformer the number N of sudden changes in the voltage within the preset time period T, and calculating the voltage occurrence within ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com