A kind of processing method of polyurethane foam material and its composite textile

A foaming material and processing method technology, applied in the field of polymer materials, can solve the problems of unstable quality, easy re-deterioration, air pollution, etc., and achieve the effect of cleaning, sanitation and more environmentally friendly interior environment and interior life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

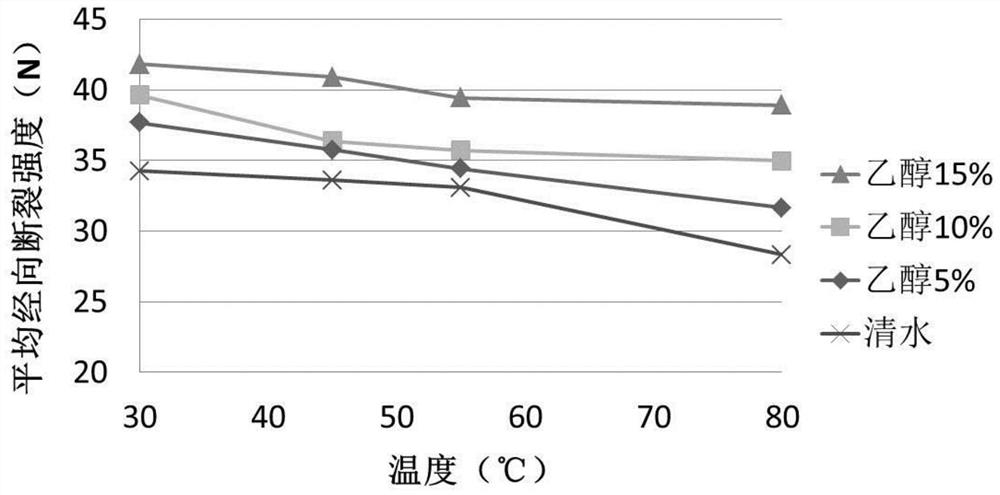

[0082] Select the polyester polyurethane sponge from Fupai Bock Company, the model is B35AGP (3.5), that is, the density of the sponge is 35kg / m 3 , the thickness is 3.5mm. After opening the package, take samples to measure the odor (according to PV3900 method) and TVOC / formaldehyde / API (PM2.5 particle concentration) and other indicators are as follows: odor level 4.99, TVOC1.359mg / m 3 , formaldehyde 0.313mg / m 3 , the API value is 208. The average longitudinal breaking strength is 34.56N (the test method is to measure the 5cm wide sponges taken at different positions on the TH-8203S tensile testing machine of Suzhou Tuobo Machinery Co., Ltd., and take the average value of the measurement results).

[0083] The following are the processing methods and steps:

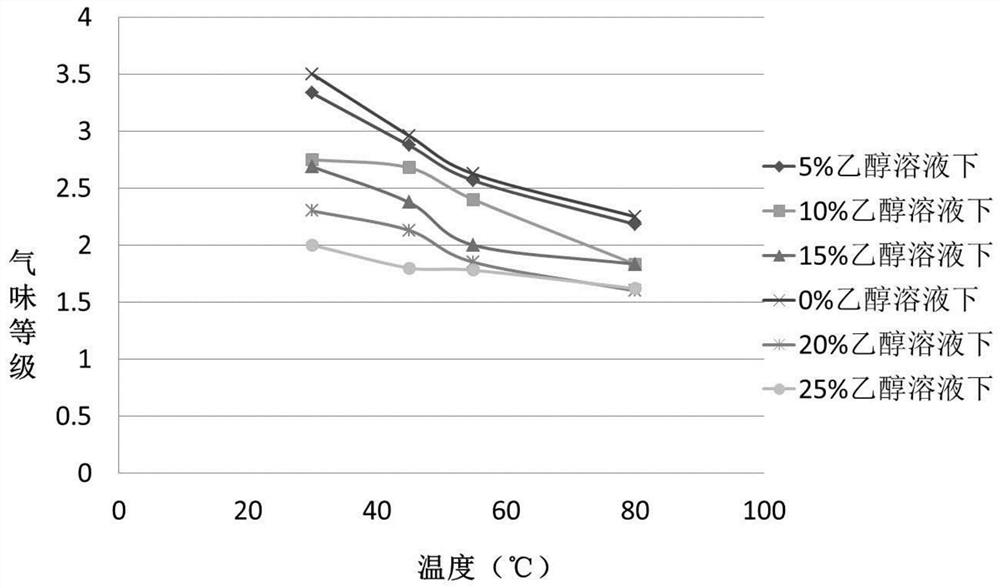

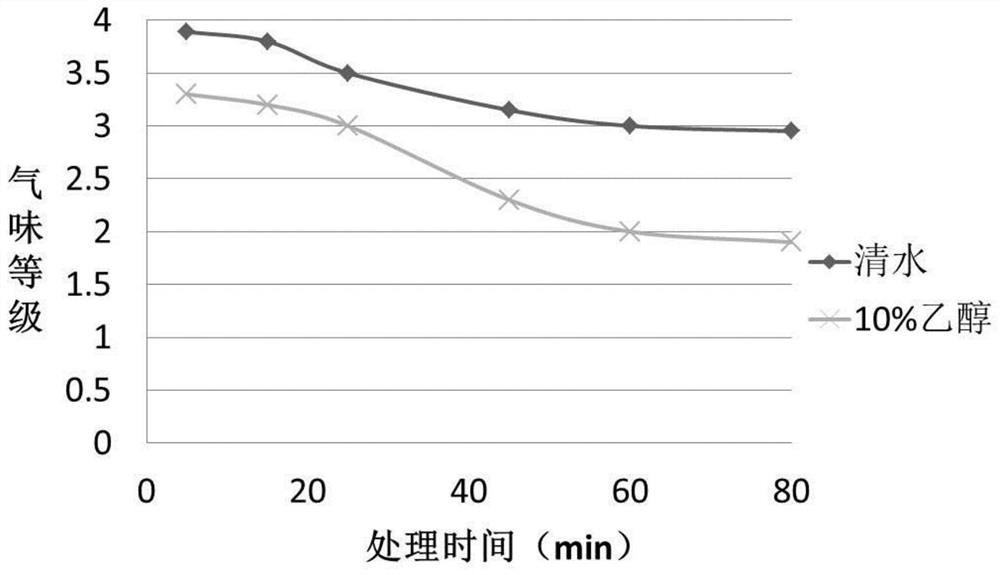

[0084] 1: Prepare a 10% concentration (mass percentage) ethanol aqueous solution and put it into a container.

[0085] 2: Heat the ethanol water solution in the container to 50°C, then remove the inner and outer packa...

Embodiment 2

[0091] Select the polyester polyurethane sponge of Changshu Weitai Sponge Products Co., Ltd., model S6169F (3.5), that is, the density of the sponge is 35kg / m 3 , thickness is 3.5mm, replaces the B35AGP (3.5) sponge of embodiment 1, and treatment method is the same as embodiment 1, and the TVOC / formaldehyde / API / odor level result before and after treatment is referring to table 2.

Embodiment 3

[0093] Select the polyester polyurethane sponge of Fupai Bock Company, model B55N (3.5), that is, the sponge density is 55kg / m 3 , thickness is 3.5mm, replaces the B35AGP (3.5) sponge of embodiment 1, and treatment method is the same as embodiment 1, and the TVOC / formaldehyde / API / odor level result before and after treatment is referring to table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com