Polyurethane foamed material and processing method of composite textile of polyurethane foamed material

A technology of foaming materials and processing methods, which is applied in the field of polymer materials, can solve problems such as unstable quality, long processing time, slow vaporization and evaporation, etc., and achieve a cleaner and more environmentally friendly car interior environment and interior life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

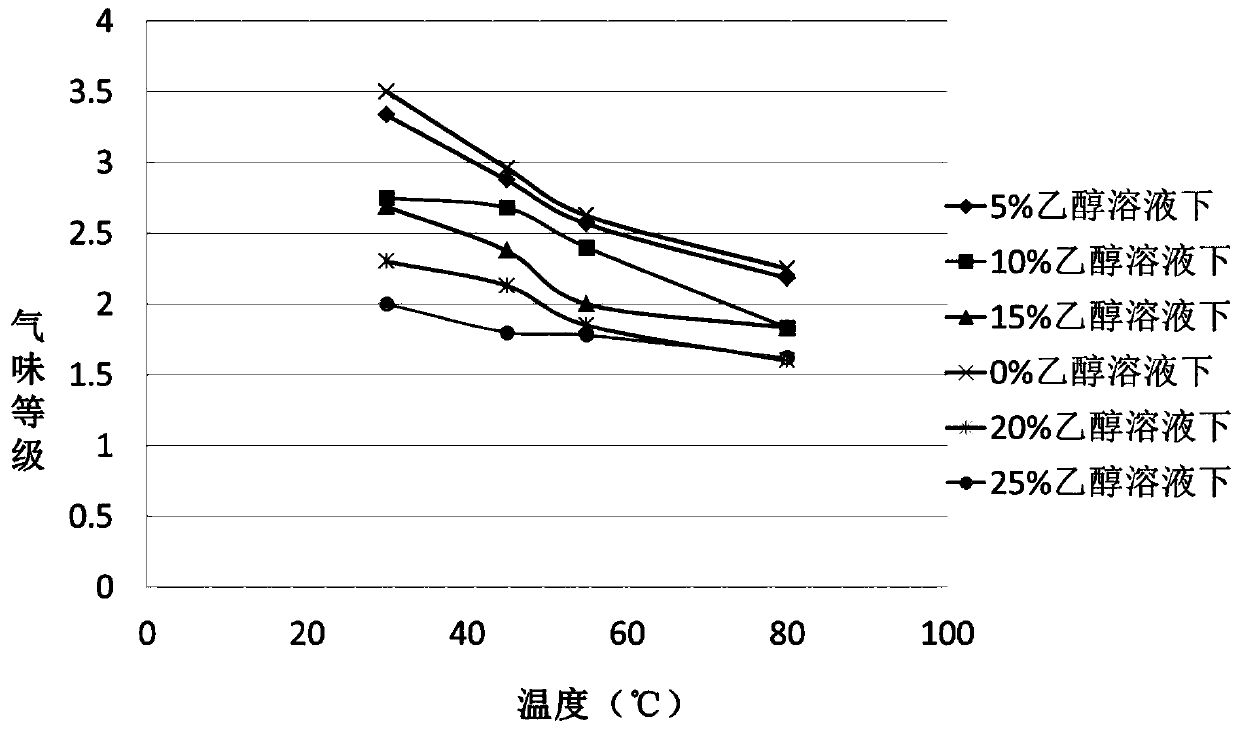

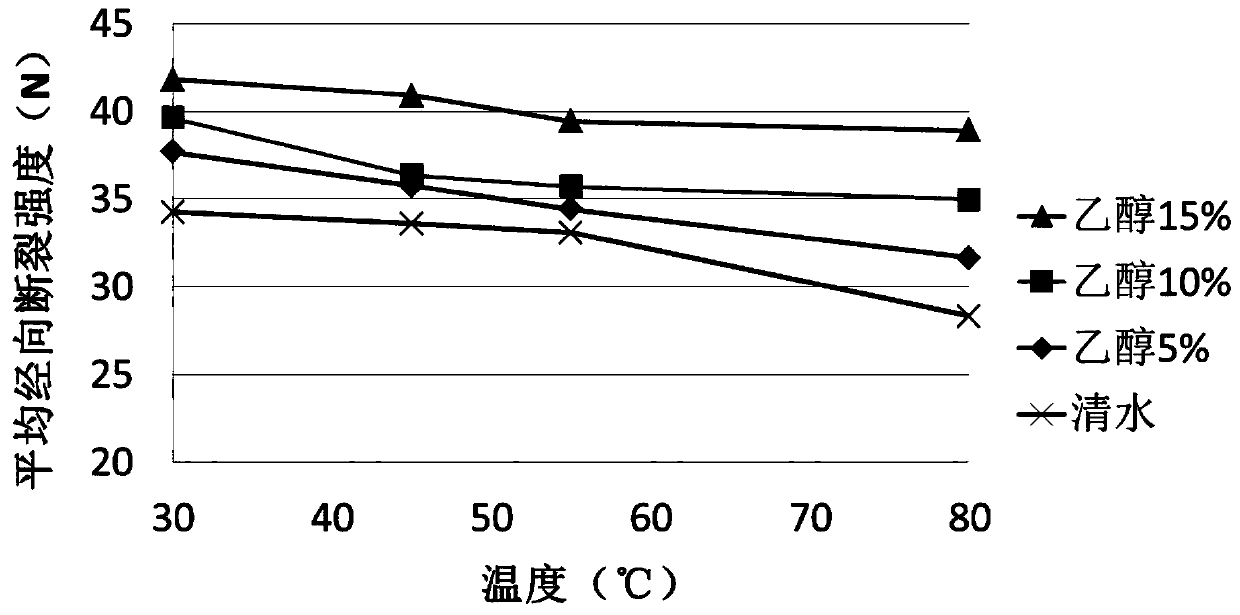

Embodiment 1

[0082] Select the polyester polyurethane sponge from Fupai Bock Company, the model is B35AGP (3.5), that is, the density of the sponge is 35kg / m 3 , the thickness is 3.5mm. After opening the package, take samples to measure the odor (according to PV3900 method) and TVOC / formaldehyde / API (PM2.5 particle concentration) and other indicators are as follows: odor level 4.99, TVOC1.359mg / m 3 , formaldehyde 0.313mg / m 3 , the API value is 208. The average longitudinal breaking strength is 34.56N (the test method is to measure the 5cm wide sponges taken at different positions on the TH-8203S tensile testing machine of Suzhou Tuobo Machinery Co., Ltd., and take the average value of the measurement results).

[0083] The following are the processing methods and steps:

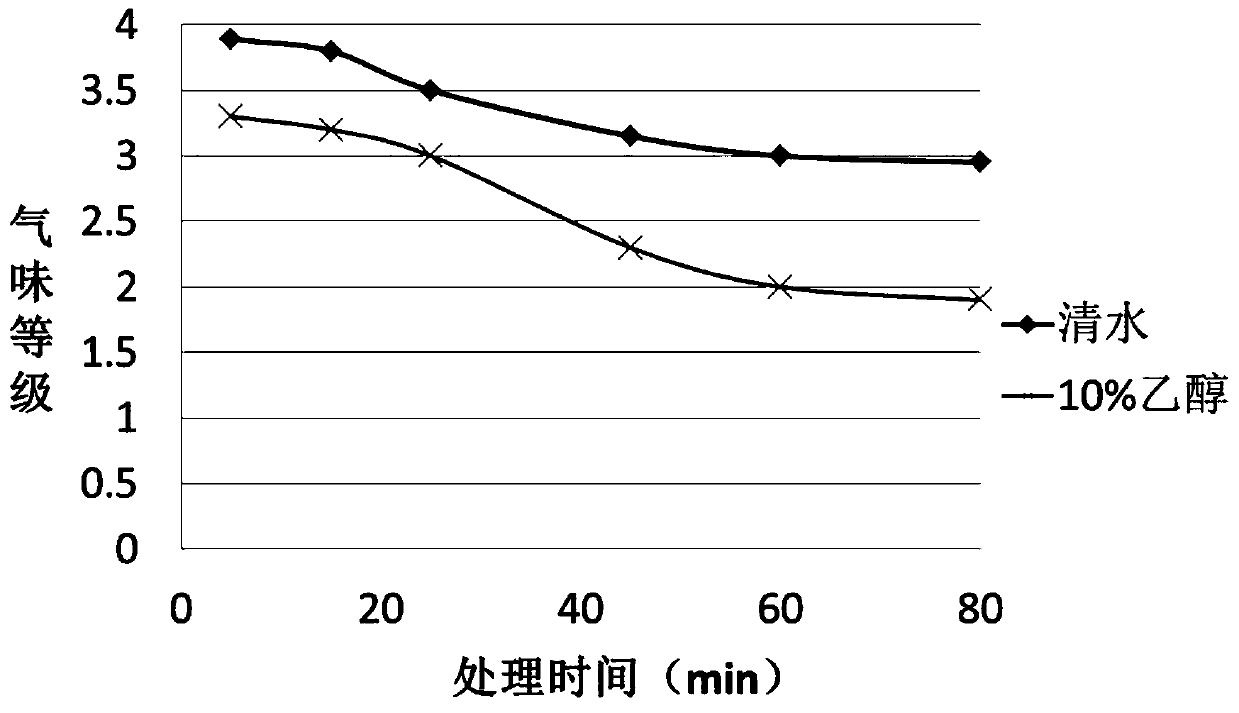

[0084] 1: Prepare a 10% concentration (mass percentage) ethanol aqueous solution and put it into a container.

[0085] 2: Heat the ethanol water solution in the container to 50°C, then remove the inner and outer packa...

Embodiment 2

[0091] Select the polyester polyurethane sponge of Changshu Weitai Sponge Products Co., Ltd., model S6169F (3.5), that is, the density of the sponge is 35kg / m 3 , thickness is 3.5mm, replaces the B35AGP (3.5) sponge of embodiment 1, and treatment method is the same as embodiment 1, and the TVOC / formaldehyde / API / odor level result before and after treatment is referring to table 2.

Embodiment 3

[0093] Select the polyester polyurethane sponge of Fupai Bock Company, model B55N (3.5), that is, the sponge density is 55kg / m 3 , thickness is 3.5mm, replaces the B35AGP (3.5) sponge of embodiment 1, and treatment method is the same as embodiment 1, and the TVOC / formaldehyde / API / odor level result before and after treatment is referring to table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com