Acid-resistant Ce-P-Co catalyst and preparation method thereof, and application for acid-resistant Ce-P-Co catalyst in synthesis of gamma-valerolactone

A ce-p-co, catalyst technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of strong acid corrosion, unable to serve the needs of industrial production, and cannot be used as a practical catalytic system to achieve Low cost, convenient large-scale preparation and application, and high industrial feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

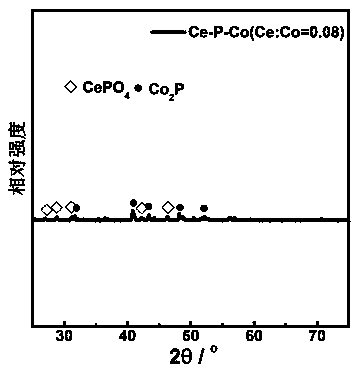

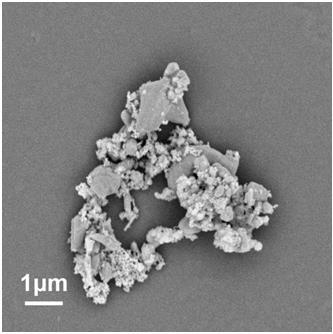

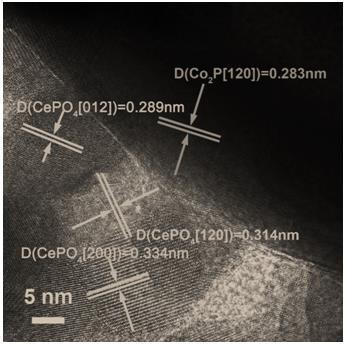

[0024] Preparation of catalyst Ce-P-Co (Ce:Co=0.08): Ce:Co=0.08 means that the molar ratio of cerium nitrate hexahydrate and cobalt nitrate hexahydrate is 0.08. Prepare salt solution A comprising 5.82 g of cobalt nitrate hexahydrate, 0.65 g of cerium nitrate hexahydrate and 50 ml of absolute ethanol. Place in a blender and stir. Prepare solution B containing 1.32 g of diammonium hydrogen phosphate and 50 ml of deionized water. Add the prepared aqueous solution B dropwise to the mixed salt solution A, and keep stirring for 1 h after the dropwise addition is complete. Afterwards, the resulting solution was transferred into a polytetrafluoroethylene hydrothermal reaction kettle, and reacted in an oven at 200° C. for 24 hours. After the reaction, the solid matter was centrifuged and washed twice with deionized water, then once with absolute ethanol, and then dried in an oven at 75° C. for 12 hours. Fill the dried solid into a quartz tube, and carry out high-temperature treatmen...

Embodiment 2

[0028]Preparation of catalyst Ce-P-Co (Ce:Co=0.17): Prepare salt solution A comprising 5.82g of cobalt nitrate hexahydrate, 1.43g of cerium nitrate hexahydrate and 50ml of absolute ethanol. Place in a blender and stir. Prepare solution B containing 1.76 g of diammonium hydrogen phosphate and 50 ml of deionized water. Add the prepared aqueous solution B dropwise to the mixed salt solution A, and keep stirring for 1 h after the dropwise addition is complete. Afterwards, the resulting solution was transferred into a polytetrafluoroethylene hydrothermal reaction kettle, and reacted in an oven at 200° C. for 24 hours. After the reaction, the solid matter was centrifuged and washed twice with deionized water, then once with absolute ethanol, and then dried in an oven at 75° C. for 12 hours. Fill the dried solid into a quartz tube, and carry out high-temperature treatment in a hydrogen atmosphere, specifically raising the temperature to 800°C at a heating rate of 5°C / min, and then ...

Embodiment 3

[0032] Preparation of the catalyst Ce-P-Co (Ce:Co=0.04): prepare a salt solution A comprising 5.82 g of cobalt nitrate hexahydrate, 0.17 g of cerium nitrate hexahydrate and 50 ml of absolute ethanol. Place in a blender and stir. Prepare solution B containing 1.32 g of diammonium hydrogen phosphate and 50 ml of deionized water. Add the prepared aqueous solution B dropwise to the mixed salt solution A, and keep stirring for 1 h after the dropwise addition is complete. Afterwards, the resulting solution was transferred into a polytetrafluoroethylene hydrothermal reaction kettle, and reacted in an oven at 200° C. for 24 hours. After the reaction, the solid matter was centrifuged and washed twice with deionized water, then once with absolute ethanol, and then dried in an oven at 75° C. for 12 hours. Fill the dried solid into a quartz tube, and carry out high-temperature treatment in a hydrogen atmosphere, specifically raising the temperature to 800°C at a heating rate of 5°C / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com