Cylindrical cathode non-equilibrium magnetron plasma gas cluster source and method of use thereof

A plasma, non-equilibrium technology, applied in the fields of atomic and molecular physics and nanoscience, which can solve the problems of limited cluster yield and cluster ion yield, and achieve high-intensity and high-ionization cluster and nanoparticle beams. The effect of flow, efficient and uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

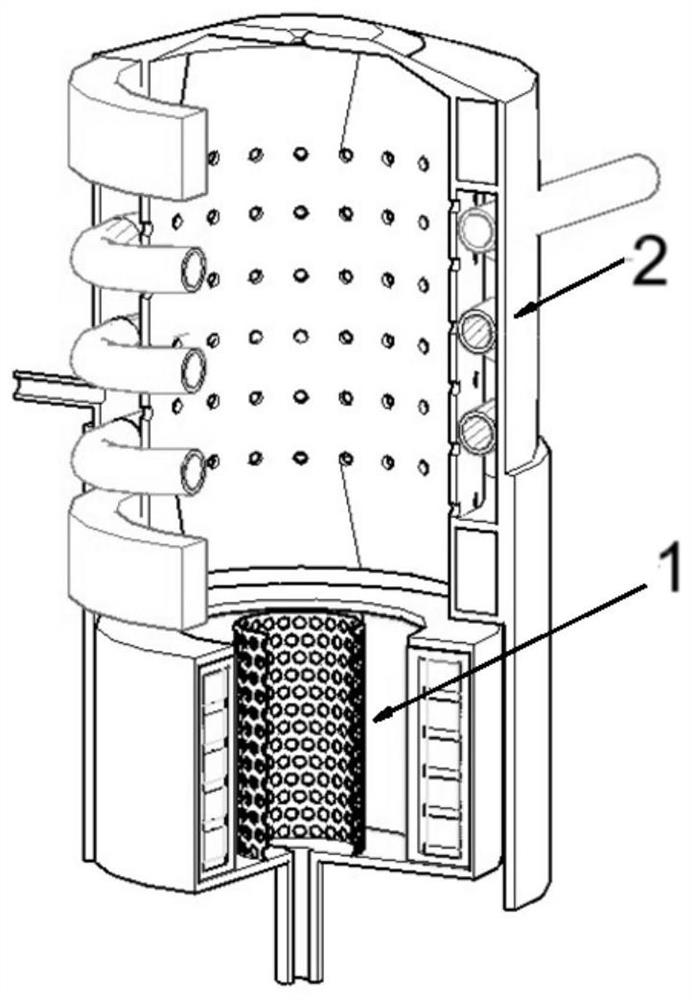

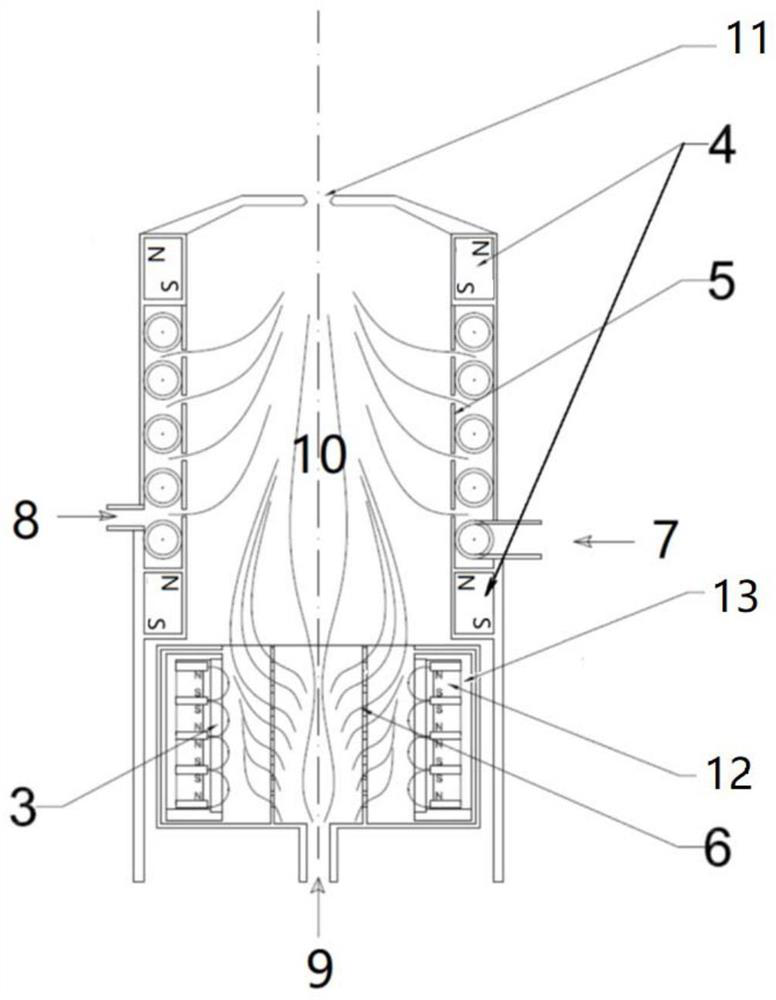

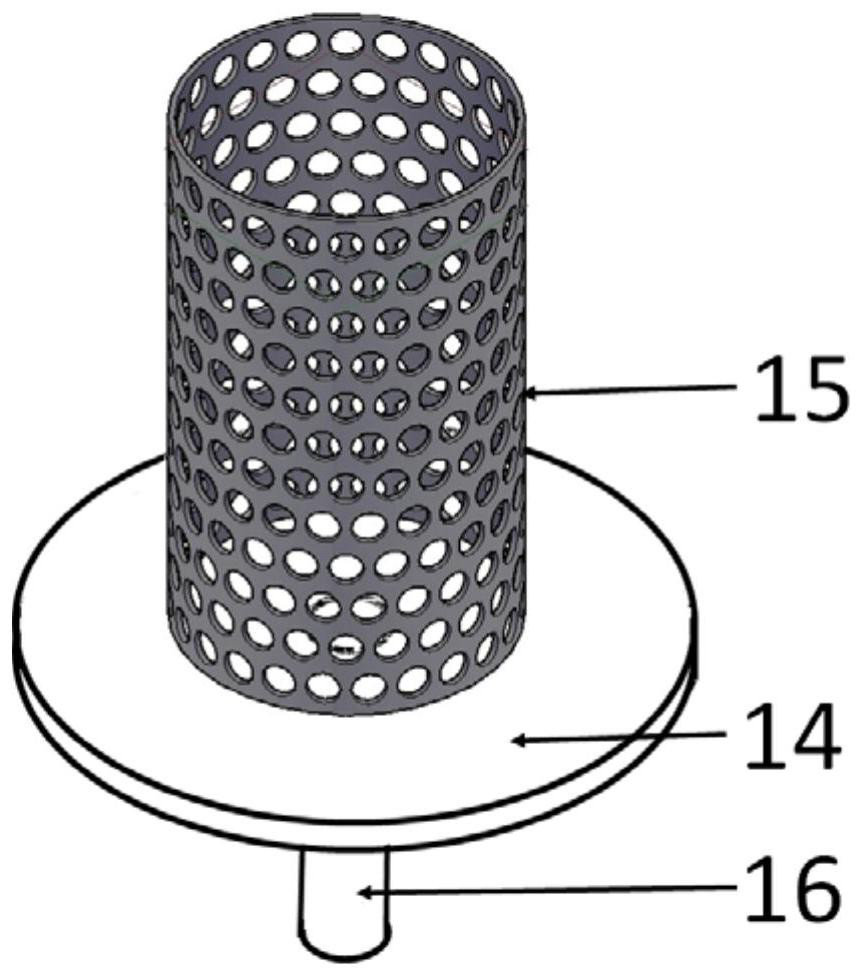

[0025] A cylindrical cathode unbalanced magnetron plasma gas cluster source, the cluster source includes a cylindrical sputtering target assembly 1 and a condensation chamber 2, and the two are connected to each other; the cylindrical sputtering target assembly 1 is sequentially arranged There is an annular cathode magnet group 12 wrapped in a sealed interlayer 13. The cylindrical sputtering target 3 and the sputtering gas are filled into the cylinder 6. The sputtering gas is filled into the bottom plate 14 of the cylinder 6 through the sputtering gas inlet 9. The vent tube 16 is filled, and flows out to the glow area between the cylindrical sputtering target 3 and the sputtering gas filling cylinder 6 through the opening on the side wall 15; the condensation chamber 2 is a vacuum-sealed chamber, and the A condensation zone 10 is formed, a nozzle 11 is provided at the center of one end of the cavity, and a differential pumping condition is formed through the nozzle 11 and the h...

Embodiment 2

[0040] A cylindrical cathode unbalanced magnetron plasma gas cluster source, the cluster source includes a cylindrical sputtering target assembly 1 and a condensation chamber 2, and the two are connected to each other; the cylindrical sputtering target assembly 1 is sequentially arranged There is an annular cathode magnet group 12 wrapped in a sealed interlayer 13. The cylindrical sputtering target 3 and the sputtering gas are filled into the cylinder 6. The sputtering gas is filled into the bottom plate 14 of the cylinder 6 through the sputtering gas inlet 9. The vent tube 16 is filled, and flows out to the glow area between the cylindrical sputtering target 3 and the sputtering gas filling cylinder 6 through the opening on the side wall 15; the condensation chamber 2 is a vacuum-sealed chamber, and the A condensation zone 10 is formed, and a nozzle 11 is provided at the center of one end of the cavity, and a differential pumping condition is formed through the nozzle 11 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com