Industrial barcode data processing method, system and medium

A data processing and data processing terminal technology, applied in the field of information management, can solve the problems of uncertain barcode direction, low production efficiency, increased equipment cost, etc., to ensure consistency, improve reading rate, and reduce input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] This embodiment provides an industrial barcode data processing method and a barcode data processing terminal device.

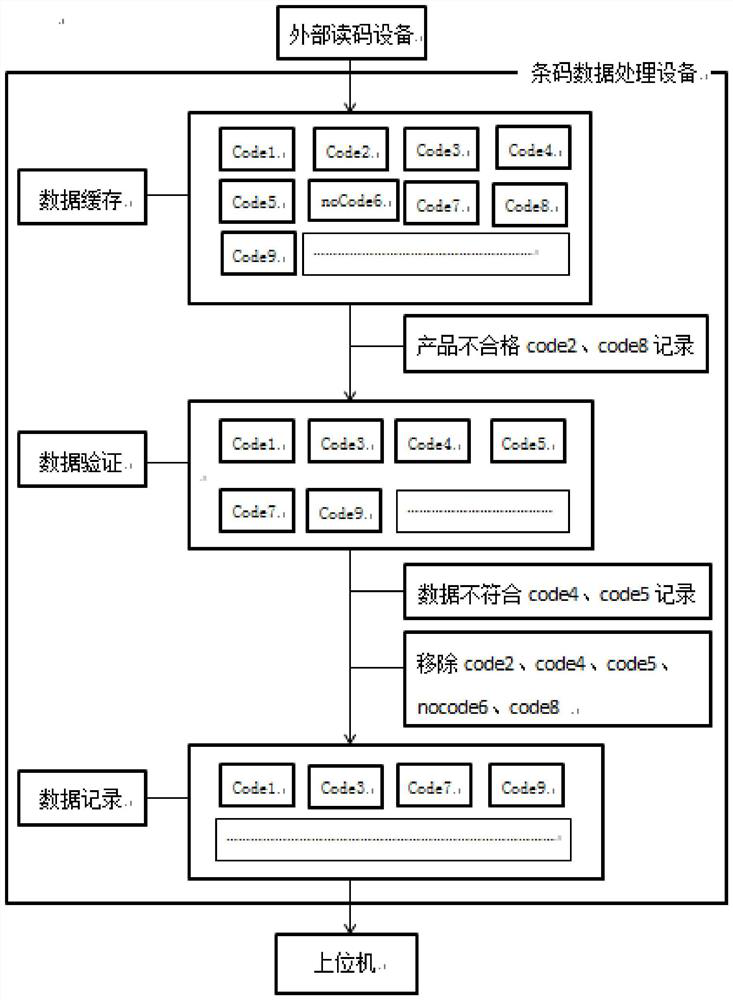

[0125] like figure 1 As shown, the industrial barcode data processing method includes: data acquisition, data caching, non-conforming product recording, data verification, data non-conforming recording, removal, data recording, and data transmission.

[0126] The method steps of the present invention are as follows:

[0127] Step 1: The external barcode reading device automatically reads the barcode and parses it, and the data (including the successfully read data and the unsuccessfully read data) is communicated to the barcode data processing terminal.

[0128] Step 2: The barcode data processing terminal receives the data and buffers it one by one.

[0129] Step 3: The industrial field monitoring equipment monitors the products, and transmits the unqualified product data obtained by monitoring to the industrial barcode data processing terminal, and ...

Embodiment 2

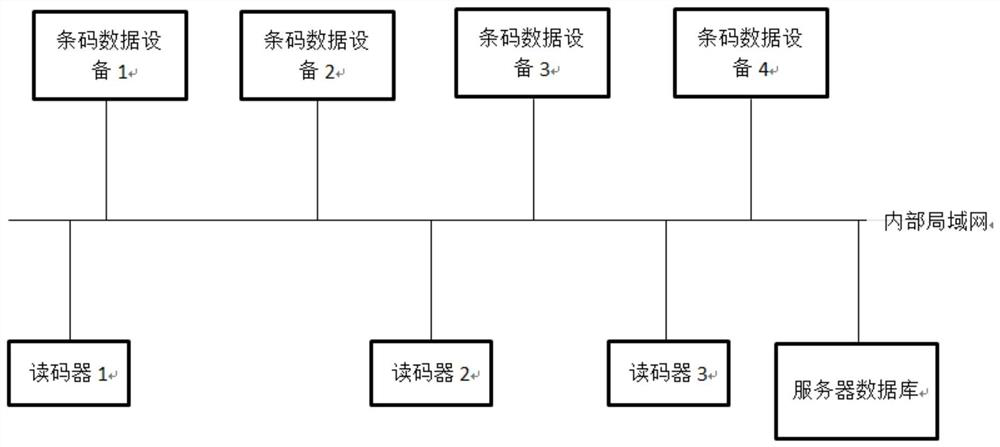

[0141] In the existing market, there are more and more demands for traceability and anti-counterfeiting through barcodes. Some products with higher added value require coded codes (the code inside the product, which can only be seen when the product is opened) and the clear code (the outer surface of the product, the appearance can be seen directly). To achieve anti-counterfeiting in a corresponding way, it is difficult to achieve this requirement with the existing technology, but this problem can be well solved by this invention. The following examples illustrate:

[0142] For a liquor brand, there is a barcode (encrypted code) in the bottle cap and a barcode (clear code) on the bottle label. The manufacturer requires that the barcode data in the bottle cap be collected and the barcode data on the bottle label correspond one by one. The manufacturer's production line is a fully automatic production line for bottle cleaning, sterilization and drying, filling, capping, labeling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com