A sample pretreatment method suitable for fast detection of heavy metal ions in water

A technology for pretreatment of heavy metal ions and samples, which is used in the preparation, sampling, and measurement devices of samples for testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

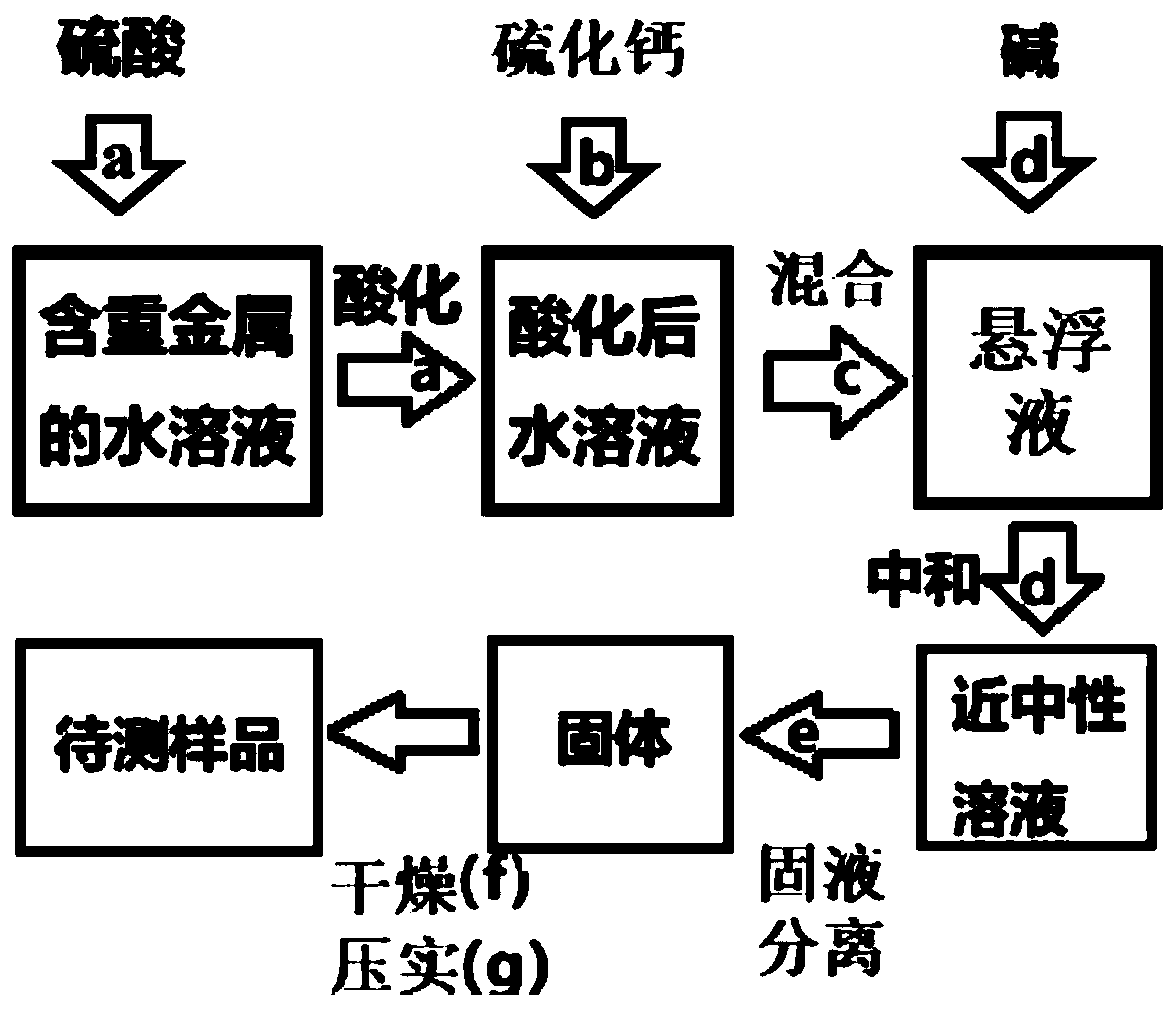

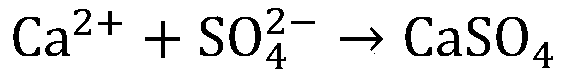

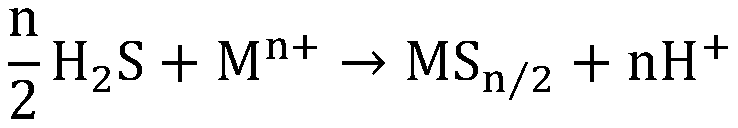

Method used

Image

Examples

Embodiment 1

[0062]Add 1g of powdered calcium sulfide to 100mL of flue gas purification copper-containing waste liquid (acidified with sulfuric acid (3g / LH2SO4) in advance), stir for 15 minutes, centrifuge, dry in an oven, compact with a hydraulic press, and use LIBS to measure the heavy metal content in the solid . The detection limit of direct detection of copper in liquid is 0.4mg / L, and the detection limit of enriched calcium sulfide is 6.5μg / L. The detection limit after enrichment was 62 times lower than direct detection.

Embodiment 2

[0064] Add 2g of powdered calcium sulfide to 100mL zinc sulphate waste liquid produced in the zinc smelting industry that has been acidified with sulfuric acid (2g / L H2SO4) in advance, stir for 10 minutes, centrifuge, dehydrate and dry with ethanol, compact with a hydraulic press, and measure the solid by XRF heavy metal content in. The detection limit of direct detection of lead in liquid is 0.7mg / L, and the detection limit of calcium sulfide enrichment is 3.5μg / L. The detection limit after enrichment is 200 times lower than direct detection.

Embodiment 3

[0066] Formulate calcium sulfide into a 100g / L emulsion, take 10mL of calcium sulfide emulsion and add it to 100mL of heavy metal wastewater with high organic matter (pre-acidified with sulfuric acid (5g / L H2SO4)), stir for 10 minutes, centrifuge, freeze-dry, and compact with a hydraulic press , using LIBS to determine the content of heavy metals in solids. The detection limit of direct detection of cadmium in liquid is 13.5mg / L, and the detection limit of enriched calcium sulfide is 13.5μg / L. The detection limit after enrichment is 1000 times lower than direct detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com