Polyamine mud shale inhibitor for drilling fluids, and preparation method thereof, and drilling fluid

A technology for mud shale and drilling fluid, which is applied in the field of polyamine mud shale inhibitor for drilling fluid and its preparation, and drilling fluid treatment agent, can solve the problems of severe reaction and difficult control, and achieves a simple and convenient preparation method. Mild effect of operation and reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] React 10g of epichlorohydrin under the catalysis of 30g of hydrochloric acid and react at 85°C for 0.5h to obtain chlorodiol; react the above chlorodiol with 10g of ethylenediamine and react at 45°C for 1.5h to obtain an intermediate product 1; react intermediate product 1, 5g ethanolamine with 0.8g thionyl chloride, react at 80°C for 0.5h to obtain intermediate product 2, then react intermediate product 2 with 10g ethylenediamine, react at 45°C for 1.5h to obtain Polyamide shale inhibitor for drilling fluid. The yield was 94.18%.

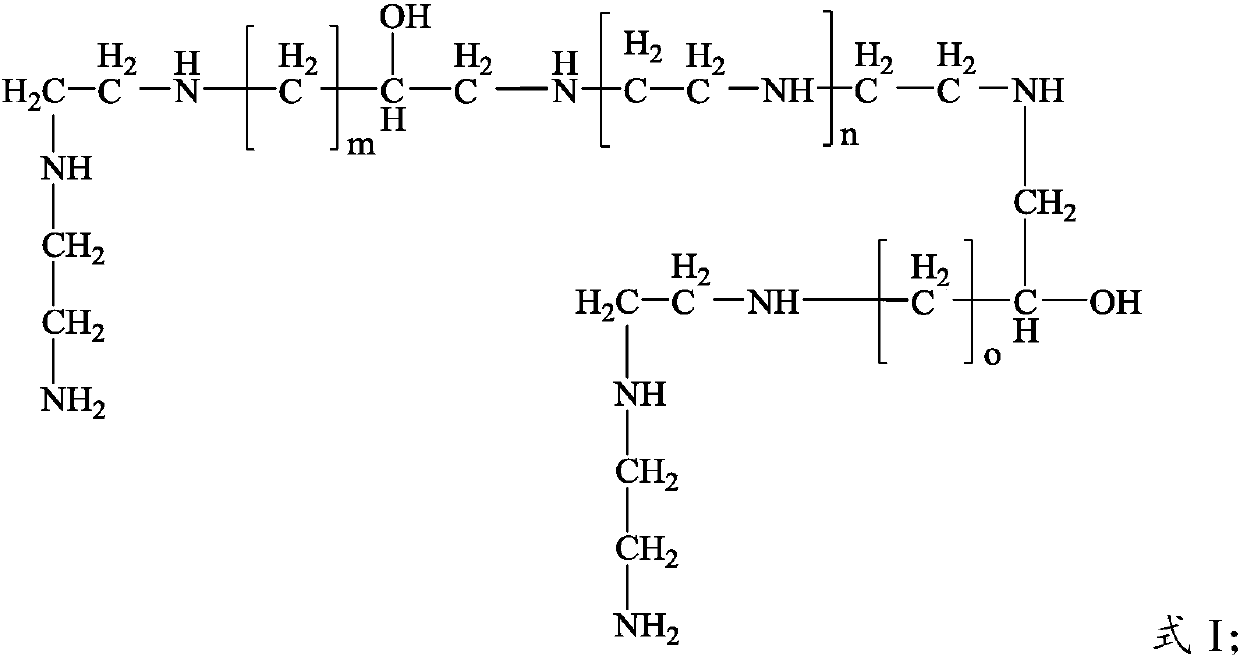

[0052] The polyamine shale inhibitor for drilling fluid prepared in Example 1 of the present invention is detected by infrared spectroscopy, and the detection result is that the polyamine shale inhibitor prepared in Example 1 of the present invention has a structure of formula I, and in formula I , m takes 1, n takes 0, and o takes 1.

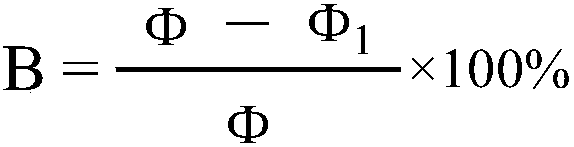

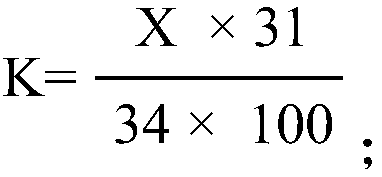

[0053] According to the method described in the above-mentioned technical scheme, test the performance o...

Embodiment 2

[0055] React 10g of epichlorohydrin under the catalysis of 35g of sulfuric acid, and react at 90°C for 1.0h to obtain chlorodiol; react the above-mentioned chlorodiol with 15g of diethylenetriamine, and react at 50°C for 2.0h to obtain intermediate Product 1: react intermediate product 1, 10 g of ethanolamine and 1.0 g of thionyl chloride for 1.0 h at 90°C to obtain intermediate product 2, then react intermediate product 2 with 15 g of ethylenediamine, and react for 2.0 h at 50°C. A polyamine shale inhibitor for drilling fluid was obtained. The yield was 95.42%.

[0056] The polyamine shale inhibitor for drilling fluid prepared in Example 2 of the present invention was detected by infrared spectroscopy, and the detection result was that the polyamine shale inhibitor prepared in Example 2 of the present invention had a structure of formula I, and in formula I , m takes 1, n takes 1, and o takes 1.

[0057] According to the method described in the above technical solution, the...

Embodiment 3

[0059] 10g of epichlorobutane was reacted under the catalysis of 40g of phosphoric acid and reacted at 95°C for 1.5h to obtain chlorodiol; the above-mentioned chlorodiol was reacted with 20g of triethylenetetramine and reacted at 55°C for 2.5h to obtain Intermediate product 1; react intermediate product 1, 15g of ethanolamine and 1.2g of thionyl chloride at 95°C for 1.5h to obtain intermediate product 2, then react intermediate product 2 with 20g of ethylenediamine and react at 55°C for 2.5h , to obtain polyamine mud shale inhibitor for drilling fluid. The yield was 96.12%.

[0060] The polyamine shale inhibitor for drilling fluid prepared in Example 3 of the present invention is detected by infrared spectroscopy, and the detection result is that the polyamine shale inhibitor prepared in Example 3 of the present invention has the structure of formula I, and in formula I , m takes 2, n takes 2, and o takes 2.

[0061] According to the method described in the above technical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com