Polylactic acid modifier, method for preparing modified polylactic acid and modified polylactic acid

A technology of polylactic acid and modifier, which is applied in the field of polylactic acid modifier and preparation of modified polylactic acid, which can solve the problems of low production efficiency and molecular weight reduction of polylactic acid, and improve impact strength, tensile strength and elongation at break. Improvement of elongation rate and effect of expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

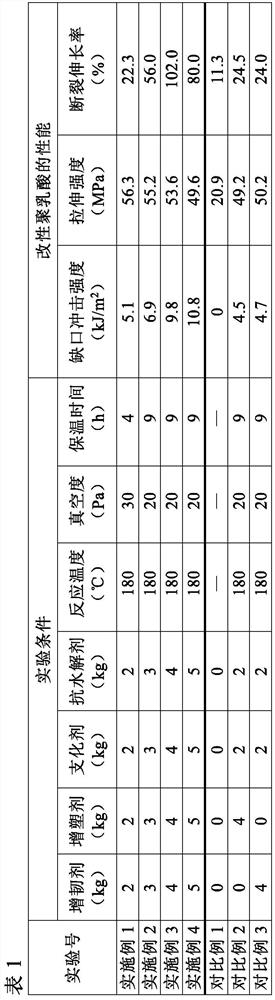

Examples

Embodiment 1

[0052] Add 100kg of lactide into the reaction kettle, then add stannous octoate as a catalyst, carry out polymerization reaction under nitrogen protection, heat up to 150°C, carry out polymerization reaction, carry out monomer removal reaction after polymerization, and obtain unmodified permanent polylactic acid melt.

[0053] Then, the obtained polylactic acid melt was modified in a vacuum state. The modification process is as follows: 4,6-diphenylthiophene [3,4-D]-1,3 -Dioxo-2-keto-5,5-dioxide was added to the above-mentioned unmodified polylactic acid melt for polymerization reaction, the reaction temperature was adjusted to 180°C, the vacuum degree was 30Pa, and the temperature was kept for 4 hours to obtain Modified polylactic acid.

[0054] After testing, its notched impact strength is 5.1kJ / m 2 ; The tensile strength is 56.3MPa; the elongation at break is 22.3%.

Embodiment 2

[0056] Add 10kg of lactide into the reaction kettle, then add stannous octoate as a catalyst, carry out polymerization reaction under the protection of nitrogen, heat to 150°C to carry out polymerization reaction, and carry out monomer removal reaction after polymerization to obtain unmodified polylactic acid melt.

[0057] Then, the obtained polylactic acid melt was modified in a vacuum state. The modification process is as follows: 4,6-diphenylthiophene [3,4-D]-1,3 -Dioxo-2-keto-5,5-dioxide is added to the above-mentioned unmodified polylactic acid melt for polymerization reaction, the reaction temperature is adjusted to 180°C, the vacuum degree is 20Pa, and the temperature is kept for 9 hours to obtain Modified polylactic acid.

[0058] After testing, its notched impact strength is 6.9kJ / m 2 ; Tensile strength of 55.2MPa; elongation at break of 56%.

Embodiment 3

[0060] Add 100kg of lactide into the reaction kettle, then add stannous octoate as a catalyst, carry out polymerization reaction under nitrogen protection, heat up to 150°C for polymerization reaction, and carry out monomer removal reaction after polymerization to obtain unmodified polylactic acid melt.

[0061] Then, the obtained polylactic acid melt was modified in a vacuum state. The modification process is as follows: 4kg of nano-titanium dioxide, 4kg of epoxidized soybean oil, 4kg of tributyl citrate and 4kg of 4,6-diphenylthiophene [3,4-D]-1,3-diox Substituted-2-ketone-5,5-dioxide was added to the above-mentioned unmodified polylactic acid melt for polymerization reaction, the reaction temperature was adjusted to 180°C, the vacuum degree was 20Pa, and the temperature was kept for 9 hours to obtain the modified polylactic acid. lactic acid.

[0062] After testing, its notched impact strength is 9.8kJ / m 2 ; The tensile strength is 53.6MPa; the elongation at break is 102...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com