A kind of processing method of high concentration p-nitrophenol

A technology of p-nitrophenol and treatment method, which is applied in the field of catalysis to achieve the effect of improving stability, increasing surface area and continuous treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

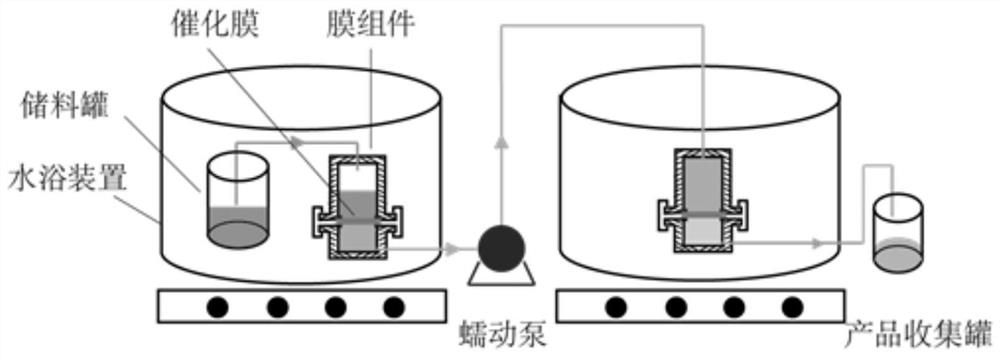

[0029] Example 1 flow-through reactor (Pd / dendritic TiO 2 Nanorod-modified Al 2 o 3 ceramic membrane) for p-nitrophenol conversion

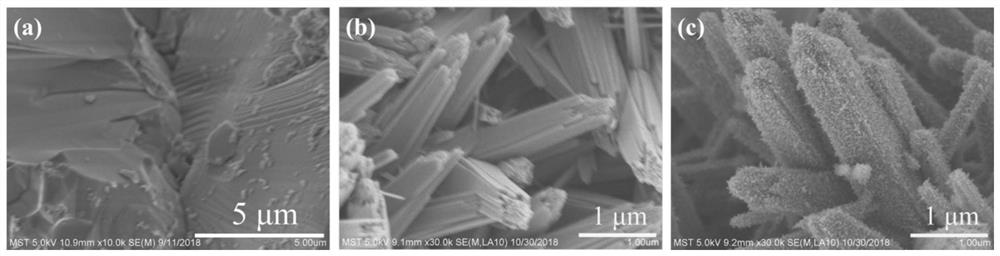

[0030] (1) Dendritic TiO 2 Nanorod-modified Al 2 o 3 Preparation of ceramic membrane

[0031] The first step of hydrothermal: Measure 20 mL of deionized water and 20 mL of hydrochloric acid, mix and stir for 5 minutes, add 0.955 mL of tetrabutyl titanate (0.07 mol / L) and stir for 10 minutes to prepare a hydrothermal solution; ceramic membrane (diameter: 3.2 cm, material: Al 2 o 3 , membrane pore size: 3 μm) was placed vertically in a 50 mL hydrothermal kettle, poured into the hydrothermal solution, and carried out hydrothermal reaction at 150 °C for 5 h, and a layer of TiO was grown on the surface of the ceramic membrane. 2 Seed.

[0032] The second step of hydrothermal: Mix 20 mL of hydrochloric acid, 20 mL of deionized water, and 3 mL of NaCl solution with a concentration of 6.16 mol / L and stir for 5 min, add 0.955 mL of tetrabutyl tit...

Embodiment 2

[0040] Example 2 flow-through reactor (Pd / dendritic TiO 2 Nanorod-modified ZrO 2 ceramic membrane) for p-nitrophenol conversion

[0041] (1) Dendritic TiO 2 Nanorod-modified ZrO 2 Preparation of ceramic membrane

[0042] The first step of hydrothermal: Measure 20 mL of deionized water and 20 mL of hydrochloric acid, mix and stir for 5 minutes, add 1.228 mL of tetrabutyl titanate (0.09 mol / L) and stir for 10 minutes to prepare a hydrothermal solution; ceramic membrane (diameter: 3.2 cm, material: ZrO 2 , membrane pore size: 200 nm) was placed vertically in a 50 mL hydrothermal kettle, poured into the hydrothermal solution, and carried out hydrothermal reaction at 180 ℃ for 5 h, and a layer of TiO was grown on the surface of the ceramic membrane 2 Seed.

[0043] The second step of hydrothermal: Mix 20 mL of hydrochloric acid, 20 mL of deionized water, and 3 mL of NaCl solution with a concentration of 4 mol / L and stir for 5 min, add 1.228 mL of tetrabutyl titanate (0.09 mol...

Embodiment 3

[0050] Example 3 flow-through reactor (Pd / dendritic TiO 2 Nanorod-modified TiO 2 ceramic membrane) for p-nitrophenol conversion

[0051] (1) Dendritic TiO 2 Nanorod-modified TiO 2 Preparation of ceramic membrane

[0052] The first step of hydrothermal: Measure 20 mL of deionized water and 20 mL of hydrochloric acid, mix and stir for 5 minutes, add 0.409 mL of tetrabutyl titanate (0.03 mol / L) and stir for 10 minutes to prepare a hydrothermal solution; ceramic membrane (diameter: 3.2 cm, material: TiO 2 , membrane pore size: 10 μm) was placed vertically in a 50 mL hydrothermal kettle, poured into the hydrothermal solution, and carried out hydrothermal reaction at 90 °C for 5 h, and a layer of TiO was grown on the surface of the ceramic membrane. 2 Seed.

[0053] The second step of hydrothermal: Mix 20 mL of hydrochloric acid, 20 mL of deionized water, and 3 mL of NaCl solution with a concentration of 2 mol / L and stir for 5 min, add 0.409 mL of tetrabutyl titanate (0.03 mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com