A kind of method and application of preparing nitrogen-doped porous carbon material with coconut shell as raw material

A nitrogen-doped porous carbon and coconut shell technology is applied in the field of preparing nitrogen-doped porous carbon materials and nitrogen-doped porous carbon materials, which can solve the problems of low safety and unfriendly environment, and achieves improved catalytic activity and preparation method. Simple and environmentally friendly, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

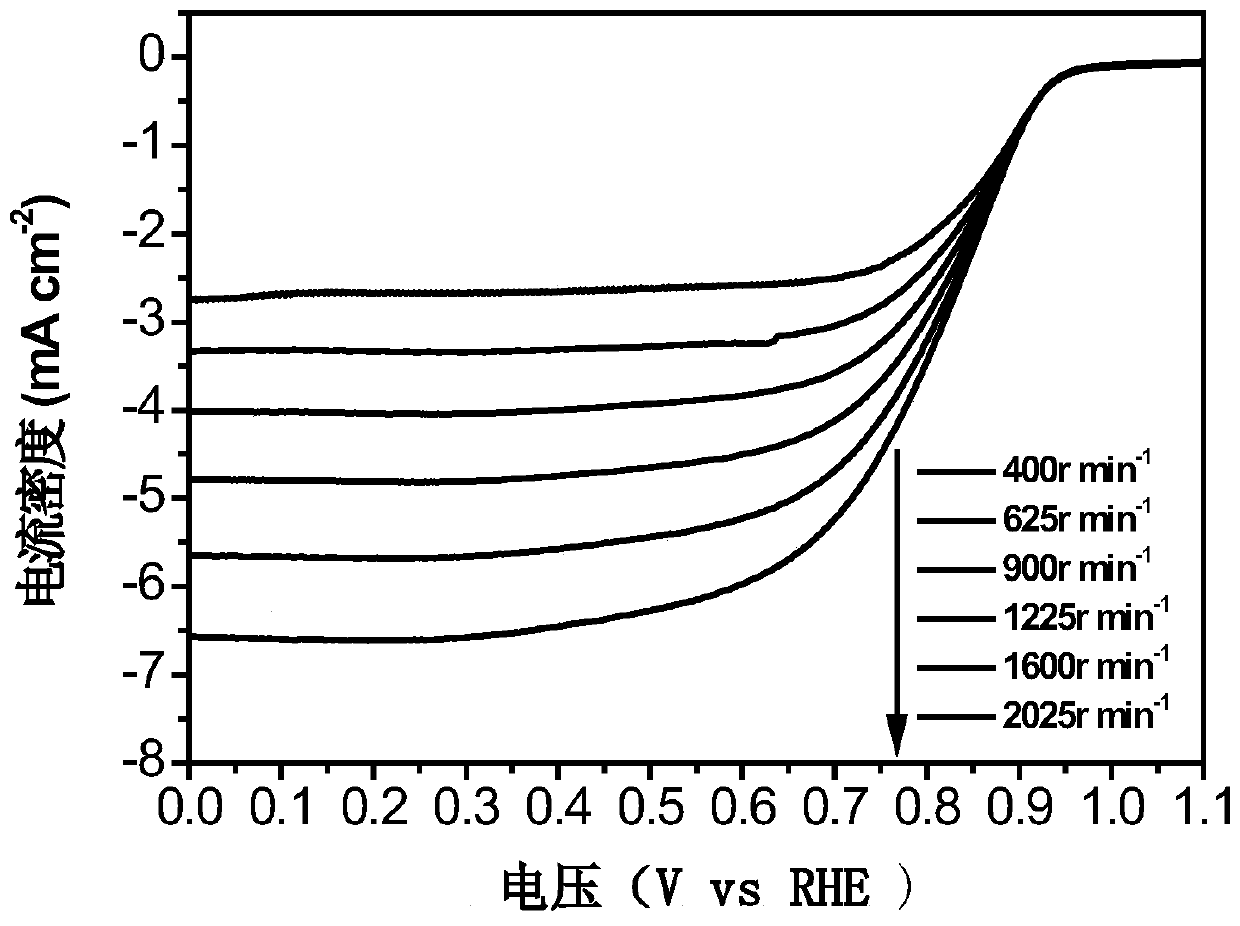

Method used

Image

Examples

Embodiment 1

[0037] (1) Break the coconut shell, sieve out the silky shredded coconut, wash and dry it with deionized water, put it into a corundum boat and put it in a tube furnace. -1 The temperature was raised to 400°C for 2 hours at a certain rate, and after the heating was completed, it was naturally cooled to room temperature to obtain pre-carbonized material A1;

[0038] (2) Transfer material A1 to a beaker, add 100ml of 6mol L at 60°C -1 Potassium hydroxide solution, 300r min -1 Stir for 8 hours, then filter with suction, wash with deionized water until the filtrate is neutral, transfer the filter cake to a beaker, and then add 100ml of 1mol L -1 HCI, 300r min -1 Stir for 1 hour, filter with suction, wash with deionized water until the filtrate is neutral, and dry to obtain material B1;

[0039] (3) Dissolve 0.15g of potassium hydroxide and 0.45g of potassium bicarbonate in deionized water to form a 20ml mixed solution. Then take 0.15g of material B1 and put it into the mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com