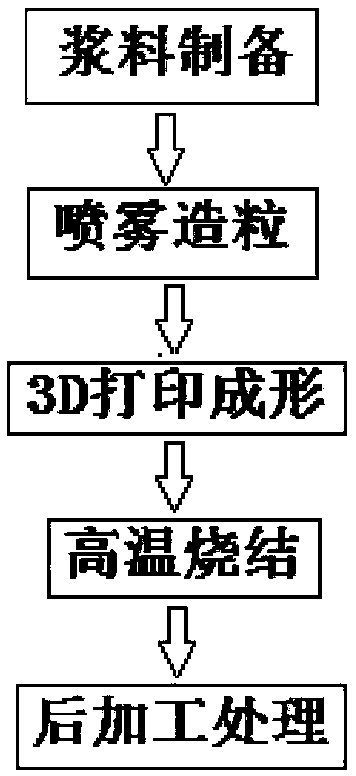

Bulk powder for 3D printing, preparation method thereof and printing method

A 3D printing and lump-like technology, applied in the field of 3D printing, can solve the problems of limited promotion, poor fluidity, uniform coating, etc., and achieve the effect of low price, increased fluidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

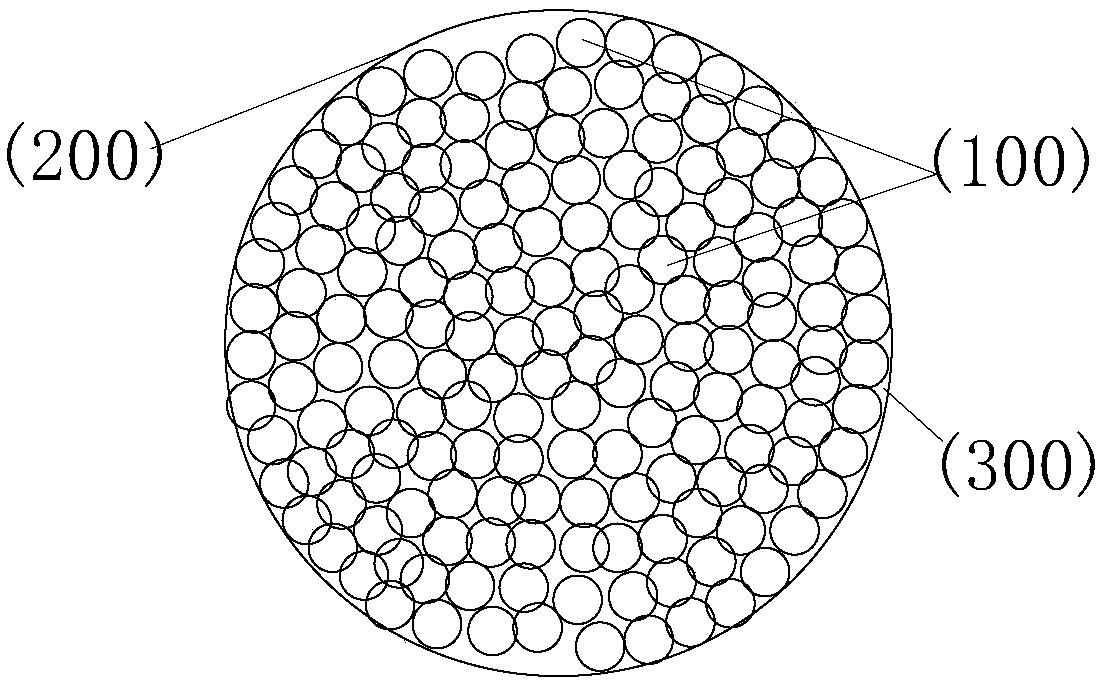

[0080] The agglomerate powder for 3D printing in this embodiment is in the shape of a sphere after spray granulation, the particle size distribution D90 of 316 metal powder is 22-25 μm, and the particle size distribution of the powder agglomerate is formed after the spray granulation process Its particle size distribution D90 is 80~120μm. The main role of the alcohol solvent here is as a carrier, which is responsible for combining the metal powder and the binder.

[0081] By weight percentage, each component content is as follows:

[0082]

[0083] The D90 is 80-120 μm powder group formed by spray-drying the dried granules, the powder accounts for 95%, and the binder accounts for 5%.

[0084] After 3D printing and forming the green body, the traditional 316L sintering curve is kept at 1360°C for 3 hours, and the sintered density can be obtained at 7.85g / cm 3 (99% relative density) product.

Embodiment 2

[0086] The agglomerate powder for 3D printing in this embodiment is in the shape of a sphere after spray granulation, the particle size distribution D90 of 316 metal powder is 22-25 μm, and the particle size distribution of the powder agglomerate is formed after the spray granulation process Its particle size distribution D90 is 80~120μm. The main role of the alcohol solvent here is as a carrier, which is responsible for combining the metal powder and the binder.

[0087] By weight percentage, each component content is as follows:

[0088]

[0089] D90 80~120μm powder is formed after spray drying, the powder accounts for 90%, and the binder accounts for 10%.

[0090] After 3D printing and forming the green body, the traditional 316L sintering curve is kept at 1360°C for 3 hours, and the sintered density can be obtained at 7.85g / cm 3 (relative density 99%) product.

Embodiment 3

[0092] A kind of agglomerate powder for 3D printing of the present embodiment, it is spherical shape after spray granulation, yttrium stabilized zirconia (3Y-ZrO 2 ) The particle size distribution D90 of the powder is 0.3-0.5 μm, and the particle size distribution of the powder cluster formed after the spray granulation process has a particle size distribution D90 of 80-120 μm. The main role of the ultrapure water solvent is as a carrier, which is responsible for stabilizing yttrium zirconia (3Y-ZrO 2 ) The powder is combined with the binder.

[0093] By weight percentage, each component content is as follows:

[0094]

[0095] D90 80~120μm powder is formed after spraying and drying, the powder accounts for 92.5%, and the binder accounts for 7.5%.

[0096] After 3D printing, the green body is made of traditional yttrium stabilized zirconia (3Y-ZrO 2 ) after sintering curve at 1450℃ for 3 hours, the sintered density can be obtained as 6.01g / cm 3 (relative density 99%) pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com