Pressure machine driven by multi-connecting-rod mechanism

A technology of multi-links and presses, applied in the field of machinery, to achieve the effects of stable operation, high product precision, and heat reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

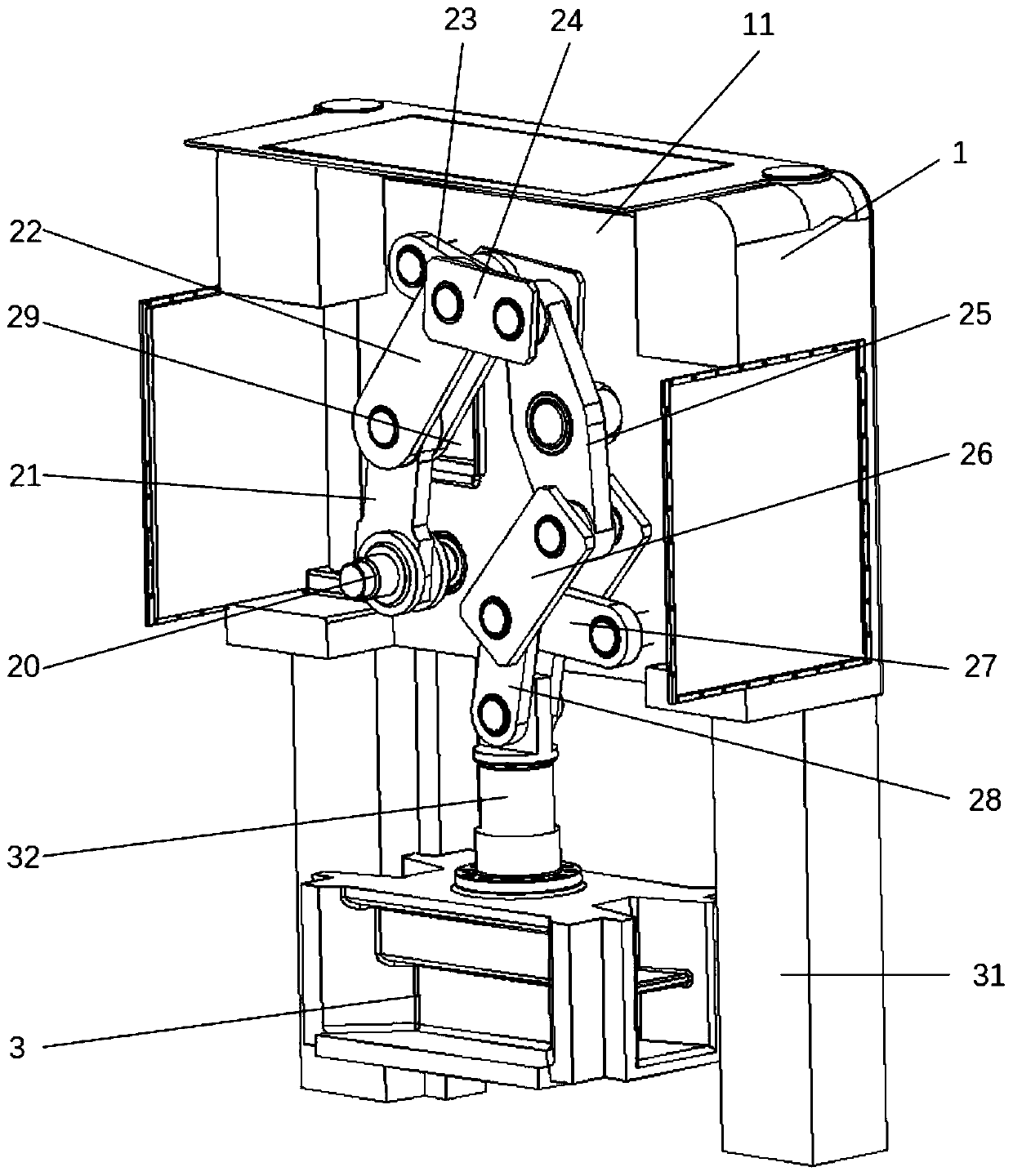

[0021] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

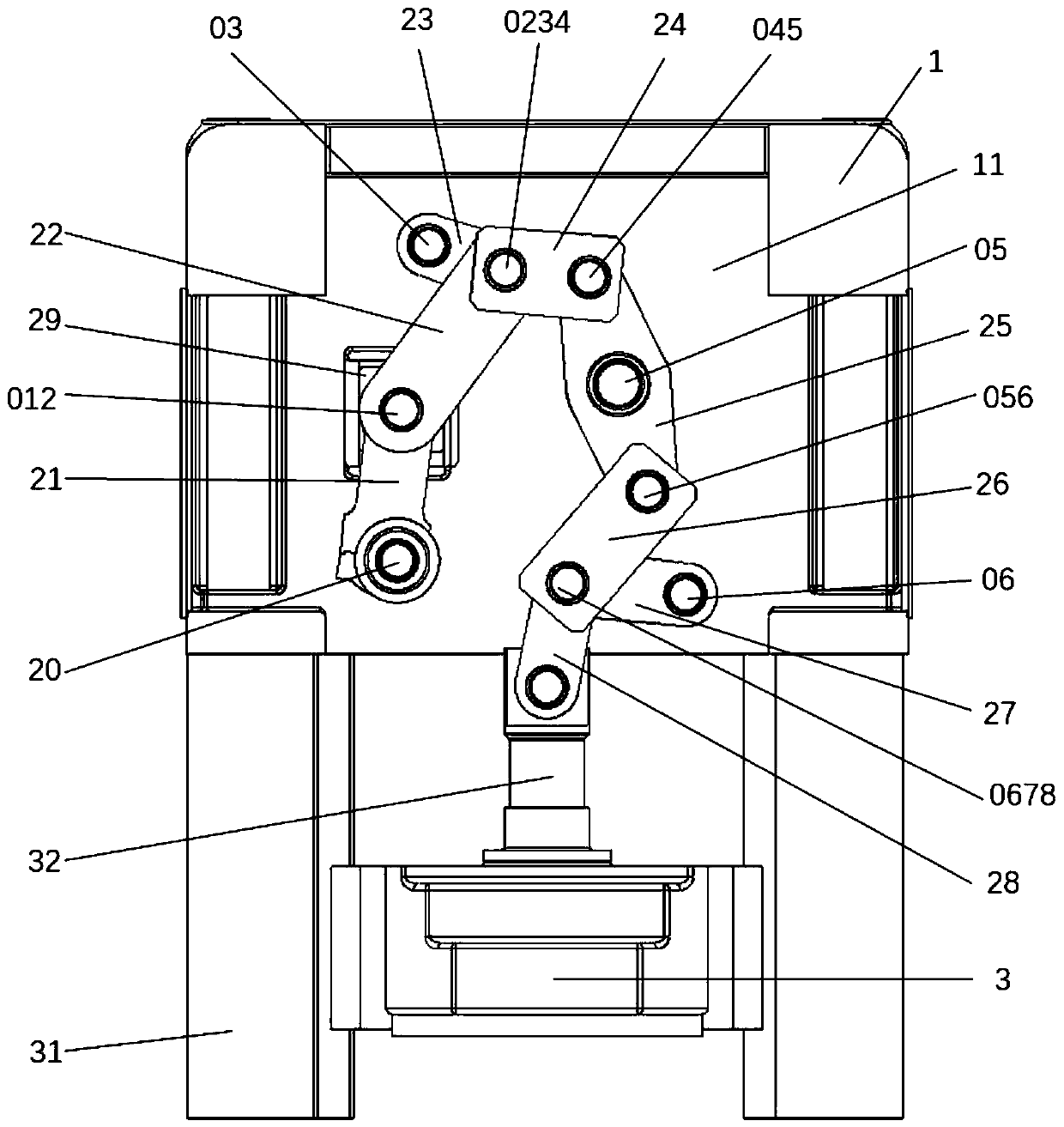

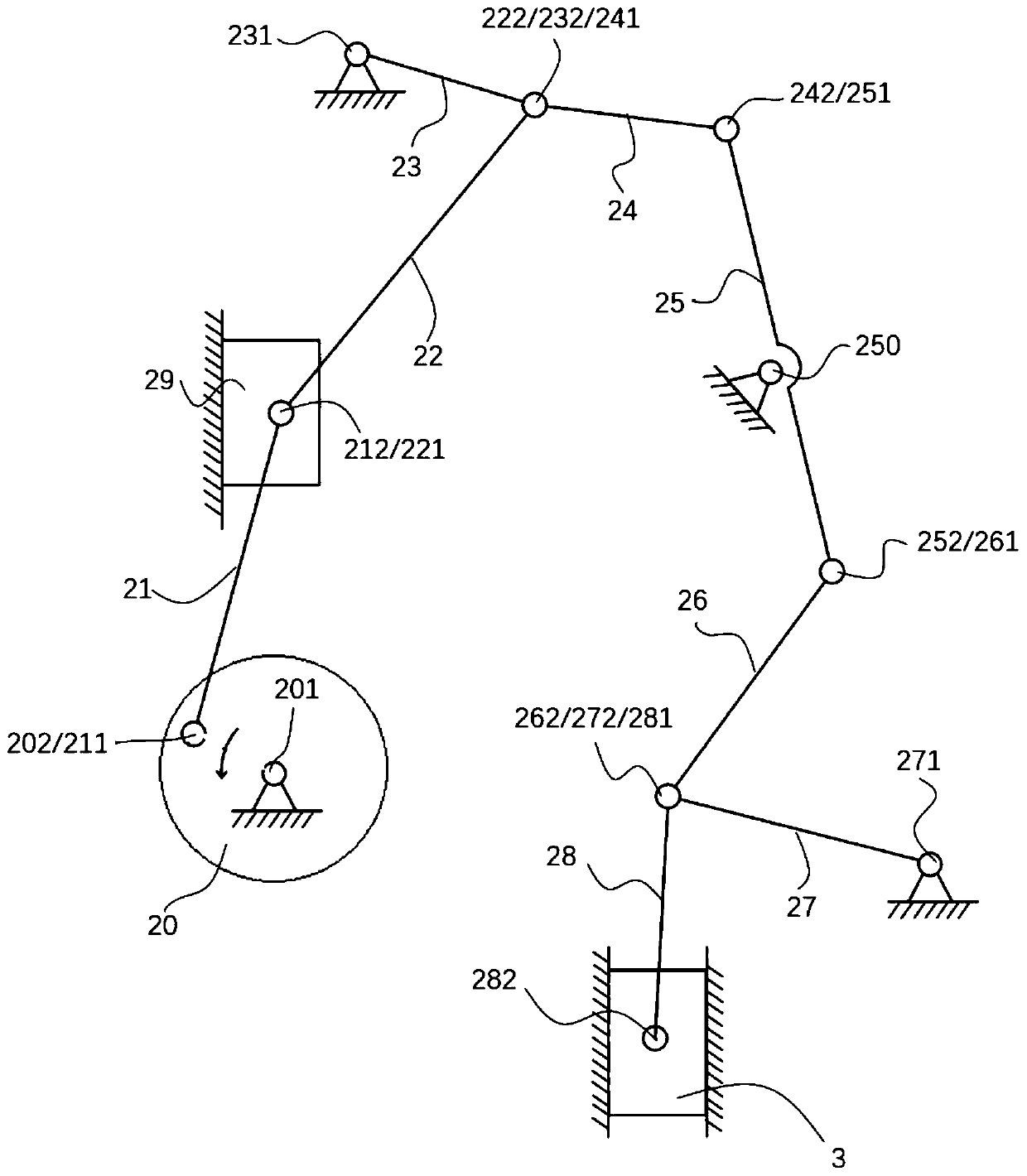

[0022] Such as Figure 1-4 As shown, the present invention provides a press machine driven by a multi-link mechanism, including a box body 1 , a mounting plate 11 , a multi-link mechanism, a stamping slider 3 , a stamping slider track 31 and a guide post 32 .

[0023] The mounting plate 11 is vertically fixed in the box body 1 .

[0024] The stamping slider track 31 is vertically fixed below the casing 1, and the stamping slider 3 can slide up and down along the stamping slider track 31.

[0025] The multi-link mechanism includes crankshaft 20, first connecting rod 21, driving slider 29, driving slider track, second connecting rod 22, A hinge shaft 012, third connecting rod 23, the Three mounting shafts 03, fourth connecting rod 24, B hinged shaft 0234, fifth connecting rod 25, fifth mounting shaft 05, C hinged shaft 045, sixth connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com