Low-noise stable permanent magnet switch reluctance motor and manufacturing process and heat dissipation method thereof

A technology of reluctance motors and permanent magnet switches, which is applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuits, etc., and can solve problems such as low conduction efficiency, unstable motor rotation, and large inrush currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

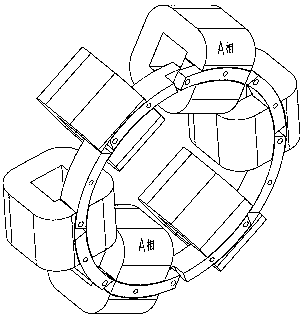

[0075] Embodiment 1, this embodiment is an air-cooled low-noise stable permanent magnet switched reluctance motor, its external shape is as attached figure 1 As shown, the structural section of this embodiment is as attached figure 2 shown.

[0076] In this embodiment, there are two stator seats 105, arranged axially opposite each other. The two stator seats 105 are fixed to the motor case 107, and the inner sides of the two stator seats 105 are respectively provided with six cavities. The cavity is arranged symmetrically and evenly centered on the axis of the motor’s rotating shaft. A number of cooling fins 104 are provided on the outer surfaces of the two stator seats 105. The C-shaped laminated iron core 112 and the excitation coil 113 form a pair of excitation salient poles. The pole pairs are respectively clamped by the upper pressing plate 111 and the lower pressing plate 114, and then embedded into the cavities inside the two stator bases respectively. The upper press...

Embodiment 2

[0086] Embodiment 2, the structure of this embodiment is basically the same as that of Embodiment 1, the only difference is that the excitation salient pole pair is composed of a C-shaped iron core, a coil bobbin and an excitation coil, see the attached Figure 13 And attached Figure 14 , the coil bobbin 171 is wrapped in a C-shaped iron core 172, and the excitation coil is wound on the coil bobbin. The coil bobbin is provided with four counterbores 170, and twelve excitation salient pole pairs are respectively embedded in the cavities inside the two stator bases. Inside the body, the screws pass through the counterbore 170 on the coil frame 171 and are fixedly connected to the stator base, and high thermal conductivity insulating glue is filled between the exciting salient pole pairs and the cavity of the stator base.

Embodiment 3

[0087] Embodiment 3, the structural section of the whole motor of this embodiment is as attached Figure 15 shown.

[0088] The structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that the rotating shaft connected and fixed with the rotor bracket is a through shaft, and the structural section is as attached Figure 16 As shown, the appearance is as attached Figure 17 shown. The flange 219 of the rotating shaft and the circular pressure plate 216 clamp the rotor bracket 210 from both sides, and are riveted into a whole by rivets 217 .

[0089] In this embodiment, through the application of compound excitation salient pole pairs, the rotational torque of the motor is further increased, the power consumption is saved, and the service efficiency of the motor is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com