Low profile vertical polarization ultra wide band omnidirectional antenna

A vertically polarized, omnidirectional antenna technology, applied in the field of antennas, can solve problems such as large antenna structure size, achieve the effects of reducing operating frequency, reducing material loss, and improving radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

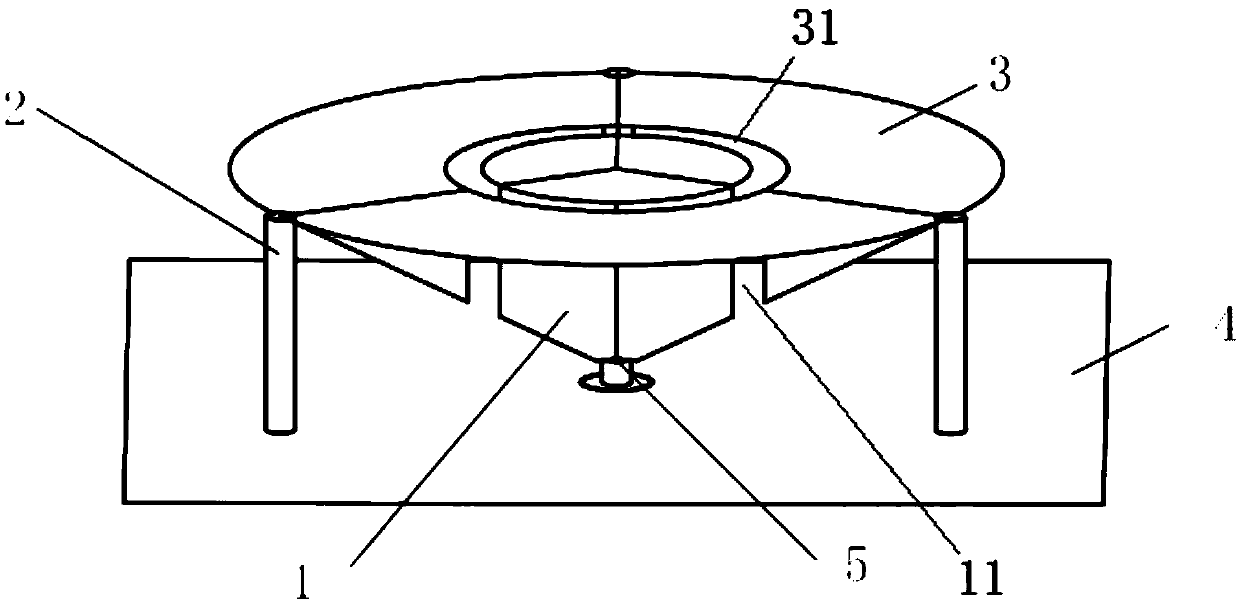

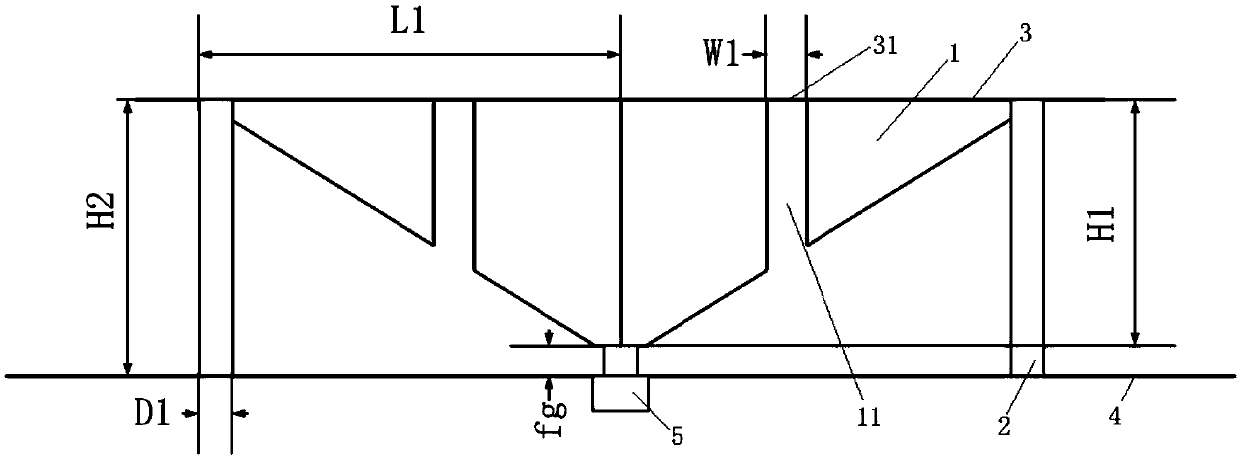

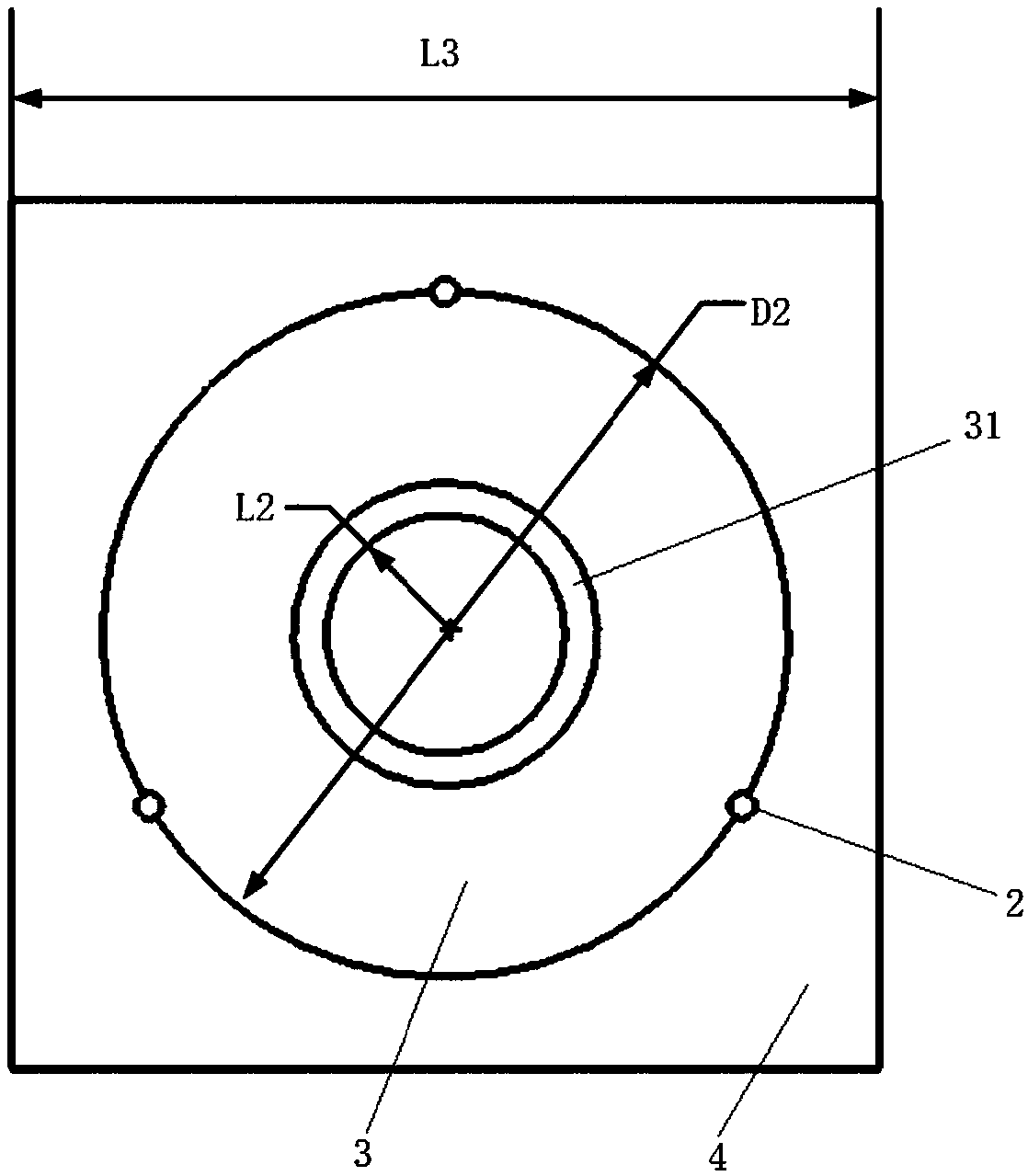

[0032] Refer to attached Figure 1-4 As shown, a low-profile vertically polarized omnidirectional antenna of the present invention includes three triangular metal sheets 1, a short-circuit metal post 2, a circular metal sheet 3, a rectangular ground plate 4 and a coaxial feeding part 5, and three triangular Metal sheet 1 includes three identical right-angled triangle metal sheets, and the shorter right-angled sides of the three right-angled triangle metal sheets are vertically arranged on the same axis; The included angle is 120°; the longer right-angle sides of the three right-angled triangle metal sheets are arranged on the upper part, and are arranged on the same plane; An annular groove 31 is arranged on it; the annular groove 31 separates the circular metal sheet 3 into an inner circular metal sheet and an outer annular metal sheet; a through groove 11 is provided on the triangular metal plate 1 corresponding to the annular groove 31, and the through groove 11 divides the...

Embodiment 2

[0041] The length L1=7mm of the longer right-angled side of the right-angled triangular metal sheet, the length H1=6mm of the shorter right-angled side; the diameter D1=1mm of the short-circuit metal post 2, and the height is H2=7mm; the diameter D2=14mm of the circular metal sheet 3 , the annular groove 31 on the circular metal sheet 3 is apart from the distance L2=7mm from the center of the circular metal sheet 1, the width of the annular groove 31 is W1=0.2mm, and the through groove width W1=0.2mm on the triangular metal sheet 1; The grounding plate 4 adopts a square metal grounding plate, and the side length of the square metal grounding plate is L3=100mm; the distance between the top of the coaxial feeding part 5 and the rectangular grounding plate 4 is fg=0.5mm, and the inside The core diameter D3 = 1 mm, the inner diameter D4 of the shell 51 is 2.3 times the inner core diameter, and the thickness is t = 0.5 mm.

Embodiment 3

[0043] The length L1=20mm of the longer right-angled side of the right-angled triangle metal sheet, the length H1=15mm of the shorter right-angled side; The diameter D1=1.5mm of short-circuit metal post 2, height is H2=16mm; The diameter D2=of circular metal sheet 3= 40mm, the annular groove 31 on the circular metal sheet 3 is apart from the distance L2=10mm of the circular metal sheet 1 circle center, the width of the annular groove 31 is W1=1.5mm, the through groove width W1=1.5mm on the triangular metal sheet 1; The rectangular grounding plate 4 adopts a square metal grounding plate, and the side length of the square metal grounding plate is L3=200mm; The core diameter D3=1.5mm, the inner diameter D4 of the shell 51 is 2.3 times the inner core diameter, and the thickness is t=2mm.

[0044] The present invention adopts a fully metallized structure, which reduces the loss of antenna materials and improves the radiation efficiency of the antenna; in Embodiments 1-3, the tradit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com