A multi-mode mining simulation device and method for different types of natural gas hydrate reservoirs

A simulation device and simulation method technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

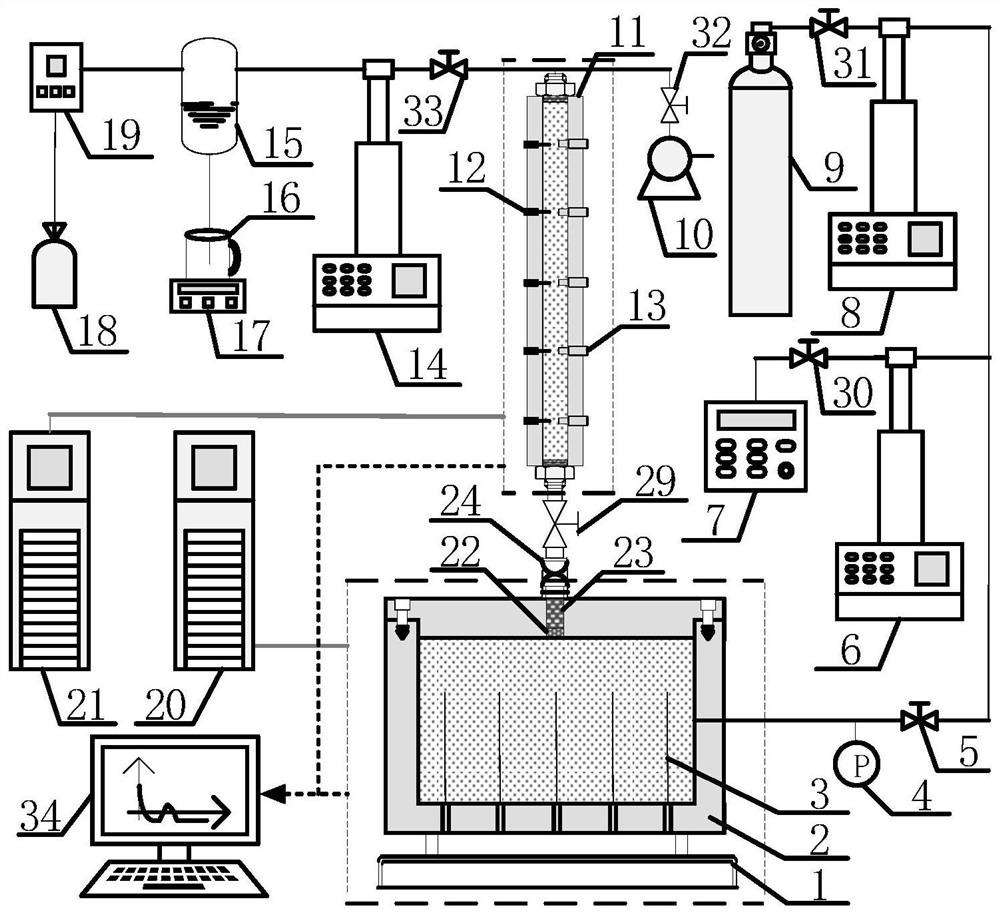

[0044] Embodiment one, refer to figure 1 , this embodiment proposes a multi-mode mining simulation device for different types of natural gas hydrate reservoirs, including a high-pressure reactor 2, a production well 11, a temperature control device, a pressure control device, a gas supply and liquid supply device, and a gas-liquid separation device and data acquisition devices.

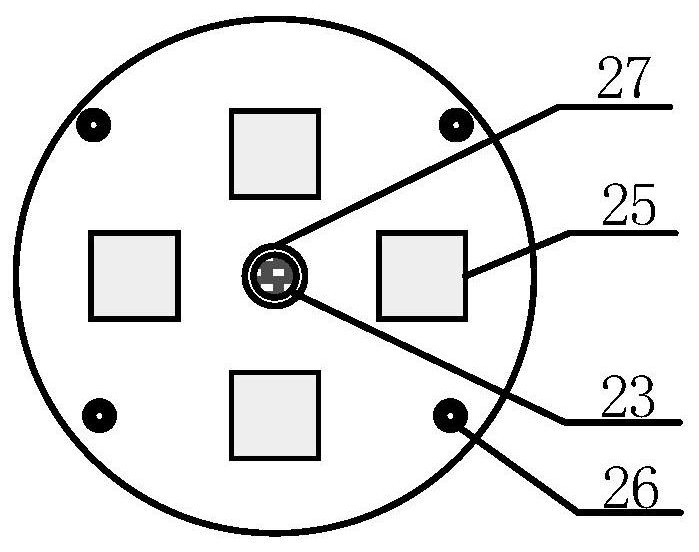

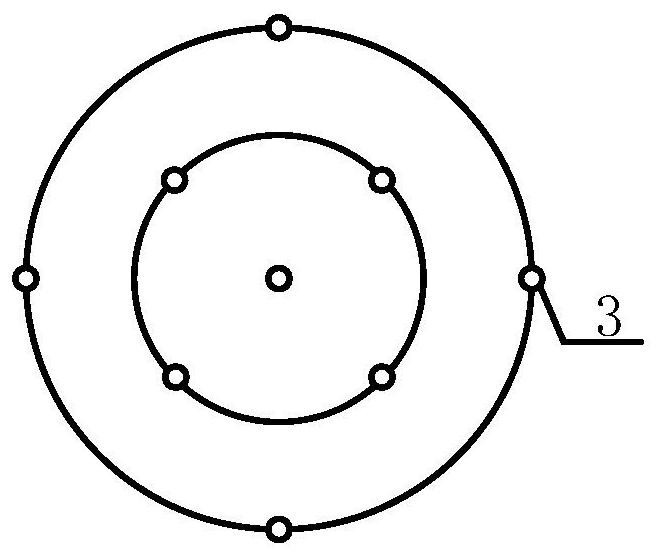

[0045] The bottom of the autoclave 2 is provided with a base 1; the bottom of the autoclave 2 is evenly provided with a plurality of multi-point measuring thermocouples 3; the center position of the upper cover of the autoclave 2 is provided with a sand control filter layer; There are four visualization windows 25; the upper cover of the autoclave 2 is connected to the kettle body through screws 26, and a sealing gasket 27 is arranged at the contact between the upper cover and the inside of the kettle body;

[0046] The inlet pipeline of the production well 11 is connected with the high-pressure reac...

Embodiment 2

[0056] Embodiment 2, this embodiment proposes a multi-mode mining simulation method for different types of natural gas hydrate reservoirs, combining figure 1 The specific steps are described as follows:

[0057] (1) Determine the type of simulated water hydrate reservoir: open the upper cover of the autoclave 2, and fill the autoclave with sediment or a mixture of sediment and ice powder, etc., according to the type of simulated water hydrate reservoir required. , Install the upper cover of the autoclave. Specifically, the types of simulated water hydrate reservoirs are divided into four types: Class 1, Class 2, Class 3 and Class 4;

[0058] A) When simulating the synthesis of Class 1 hydrate reservoirs, first open the water bath 20 to lower the temperature in the autoclave 2 to below zero, open the upper cover of the autoclave 2, and fill a small amount of non- Aqueous deposits and compaction, which are then filled with a mixture of sediment and ice powder and compacted;

...

Embodiment 3

[0072] Embodiment 3, this embodiment proposes a multi-mode mining simulation method for different types of natural gas hydrate reservoirs, the difference from Embodiment 2 lies in step (3), also refer to figure 1 ,Described as follows:

[0073] Step (3), open the manhole cover 28 at one end of the production well 11, fill the deposit of supersaturated water in the production well 11, after installing the manhole cover 28, adjust the angle of the rotating pipe 24 connected with the production well 11 so that the production well 11 is placed horizontally . This scheme is used to simulate the situation where the gas-water after hydrate decomposition near the production well 11 flows through the sediment containing supersaturated water after the hydrate decomposition near the production well 11 is completed as the seabed natural gas hydrate is continuously exploited.

[0074] Other steps are similar to Embodiment 2, and will not be repeated here.

[0075] The methods proposed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com