Battery with a Thermal Tripping Element

A battery, thermal trigger technology, applied in the direction of batteries, electrical components, secondary batteries, etc., can solve the problems of battery safety hazards, battery damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

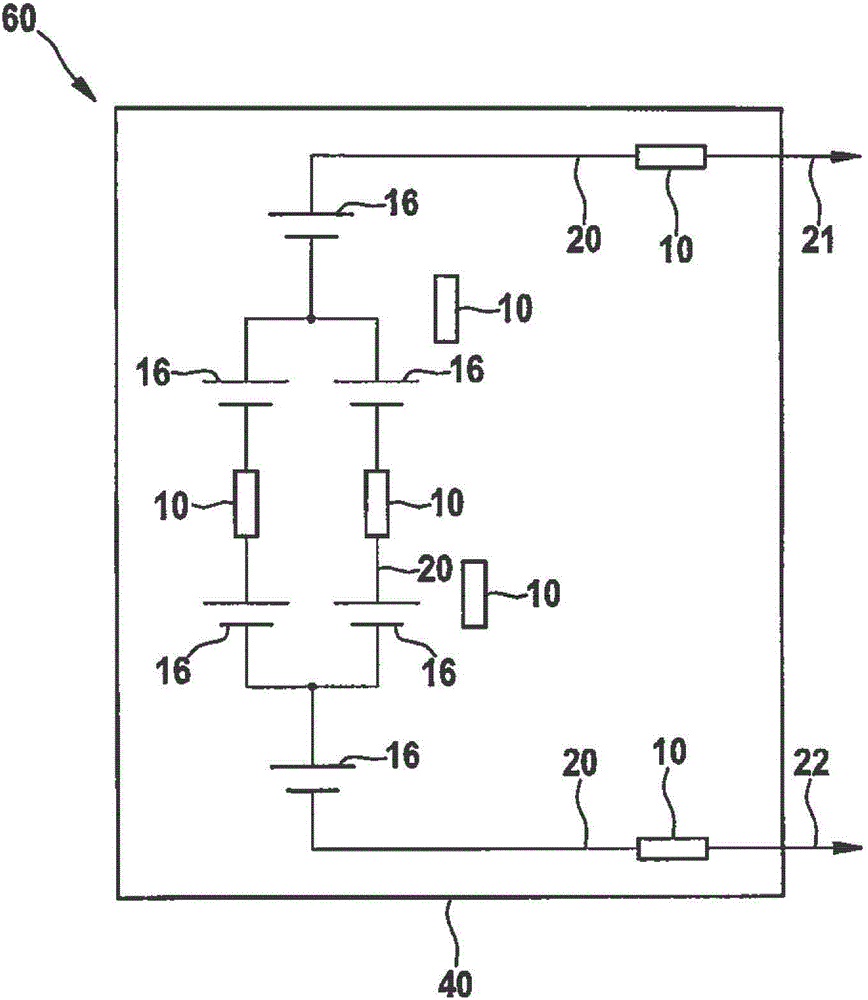

[0022] exist figure 1 An exemplary embodiment of a schematically represented battery 60 according to the invention is shown in FIG. The battery 60 includes a battery case 40, which is figure 1 Only schematically depicted in , as well as the two terminals 21 and 22, via which the battery 60 can be electrically conductively connected to the load or to the high-voltage grid, more precisely to the main protective device of the high-voltage grid. A battery pack 20 is arranged inside the battery housing 40 , which connects the two terminals 21 , 22 to each other and which has a plurality of battery cells 16 in the exemplary embodiment, some of which are connected in series to the battery pack 20 and Others are connected in parallel to the battery pack 20 and the further battery cells 16 . The battery pack 20 is also an electrical connection between the connections 21 and 22 , which in the exemplary embodiment has a plurality of battery cells 16 connected in series or in parallel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com