Aluminum alloy template release agent and preparation method thereof

A technology of aluminum alloy formwork and release agent, which is applied in the direction of manufacturing tools, lubricating compositions, petroleum industry, etc., can solve the problems of easy pollution of steel and concrete surfaces, easy delamination, high cost, etc., and achieve good economic benefits and application The effect of foreground, uniform water dispersion and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

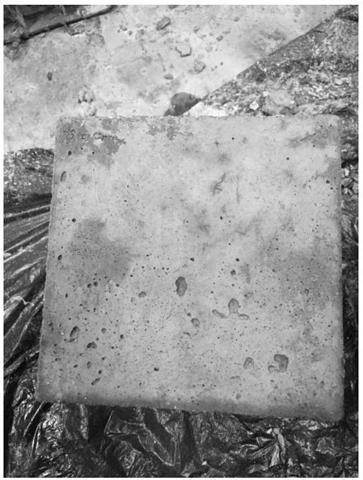

Image

Examples

Embodiment 1

[0040] A new type of aluminum alloy formwork release agent, the components are calculated in parts by weight: 10 parts of range hood condensate (wherein the content of alkanes is 15wt%, the content of olefins is 0.1wt%, and the content of sulfur is 0.01wt% , the content of solid particles is 1.0%), 3 parts of emulsifier, 4 parts of fatty alcohol ether sodium sulfate, 2 parts of dispersant, 1 part of rust inhibitor, 0.002 part of preservative, 0.1 part of thickener, 100 parts of water; The preparation method includes the following steps: add the weighed emulsifier, fatty alcohol ether sodium sulfate, range hood condensate oil, dispersant, and rust inhibitor into the reaction kettle, heat to 70°C, and stir evenly, react for 2 hours, react After the end, lower the temperature to room temperature to obtain a mixed oil phase; slowly add water to the mixed oil phase, heat to 50°C, and stir for 30 minutes to obtain a primary emulsion; finally add a thickener and preservative, continue...

Embodiment 2

[0044] A new type of aluminum alloy formwork release agent, the components are calculated in parts by weight: 15 parts of range hood condensate (wherein the content of alkanes is 20wt%, the content of olefins is 0.15wt%, and the content of sulfur is 0.015wt% , the content of solid particles is 1.5%), 4 parts of emulsifier, 4 parts of fatty alcohol ether sodium sulfate, 4 parts of dispersant, 3 parts of rust inhibitor, 0.005 part of preservative, 0.4 part of thickener, 100 parts of water; The preparation method includes the following steps: add the weighed emulsifier, fatty alcohol ether sodium sulfate, range hood condensate oil, dispersant, and rust inhibitor into the reaction kettle, heat to 70°C, and stir evenly, react for 2 hours, react After the end, lower the temperature to room temperature to obtain a mixed oil phase; slowly add water to the mixed oil phase, heat to 50°C, and stir for 30 minutes to obtain a primary emulsion; finally add a thickener and preservative, conti...

Embodiment 3

[0048] A new type of aluminum alloy formwork release agent, the components are calculated in parts by weight: 20 parts of range hood condensate (wherein the content of alkanes is 30wt%, the content of olefins is 0.2wt%, and the content of sulfur is 0.02wt% , the content of solid particles is 2.0%) 5 parts of emulsifier, 5 parts of fatty alcohol ether sodium sulfate, 4 parts of dispersant, 3 parts of rust inhibitor, 0.008 part of preservative, 0.8 part of thickener, 100 parts of water; Its preparation The method includes the following steps: add the weighed emulsifier, fatty alcohol ether sodium sulfate, range hood condensate oil, dispersant, and rust inhibitor into the reaction kettle, heat to 70°C, and stir evenly, react for 2 hours, and the reaction ends Then lower the temperature to room temperature to obtain a mixed oil phase; slowly add water to the mixed oil phase, heat to 50°C, and stir for 30 minutes to obtain a primary emulsion; finally add a thickener and preservative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com