Tough soybean meal protein adhesive and preparation method thereof

An adhesive and protein glue technology, which is applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problem of formaldehyde release from glued wood-based panels, uneven distribution of cross-linked structures, and dry strength of floor substrates Poor and other problems, to achieve excellent bonding performance, improve the performance of adhesives, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

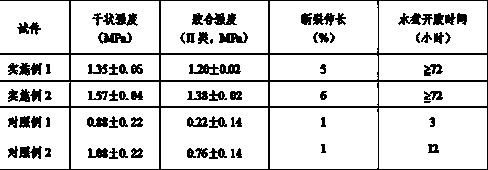

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing raw materials of an aldehyde-free protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0030] Demineralized water 70 kg

[0031] Defatted Soy Protein Powder 35 kg

[0032] Polysaccharase 0.1kg

[0033] Cellulase 0.1kg

[0034] Sodium hypochlorite 2.0kg

[0035] Triethylenetetramine 0.2kg

[0036] Toughener 1.0kg

[0037] Polyether polyol diglycidyl ether 2.0kg

[0038] Among them, defatted soy protein powder with a protein content of more than 52% was purchased from Huifu Grain and Oil Co., Ltd.; other materials were purchased from Beijing Chemical Reagent Co., Ltd.

[0039] This embodiment also provides the preparation method of the above-mentioned soybean meal protein adhesive: stir the prepared soybean meal protein adhesive prepolymer and polyether polyol diglycidyl ether at room temperature for 10 minutes, stir well and then use.

Embodiment 2

[0041] This embodiment provides a method for preparing raw materials of an aldehyde-free protein adhesive, and the adhesive is prepared according to the following weight ratio:

[0042] Demineralized water 70 kg

[0043] Defatted Soy Protein Powder 35 kg

[0044] Polysaccharase 0.3kg

[0045] Cellulase 0.1kg

[0046] Sodium hypochlorite 5.0kg

[0047] Triethylenetetramine 0.5kg

[0048] Toughener 3.0kg

[0049] Polyether polyol diglycidyl ether 4.0kg

[0050] Among them, defatted soy protein powder with a protein content of more than 52% was purchased from Huifu Grain and Oil Co., Ltd.; other materials were purchased from Beijing Chemical Reagent Co., Ltd.

[0051] The preparation method of the adhesive described in this embodiment is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com