Method for rapidly sintering NBT piezoelectric ceramic at low temperature

A piezoelectric ceramic and rapid sintering technology, which is applied in the field of low-temperature rapid sintering of NBT piezoelectric ceramics, can solve the problems of grain growth, the appearance of impurity phases, and the performance degradation of NBT piezoelectric ceramics, and achieves broad application prospects and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

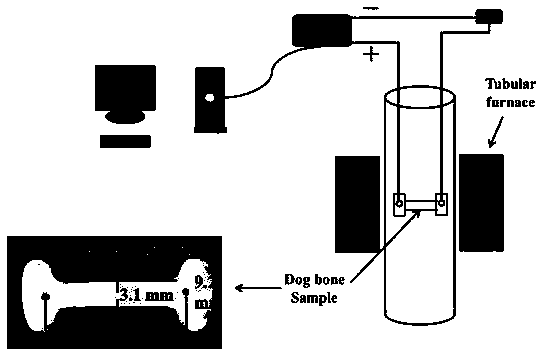

[0026] The NBT ceramic powder was pressed into a dog-bone-shaped green body by molding technology, and then pressed under 200MPa cold isostatic pressing for 180s. Place the NBT ceramic green body in the sintering furnace, and connect the green body to the DC high voltage power supply through platinum wires, such as figure 1 shown. Set the electric field to 120V / cm, and the limiting current density to 30mA / mm 2 , then raise the temperature of the sintering furnace from room temperature to 850°C, the heating rate is 10°C / min, the power supply is changed from constant voltage mode to constant current mode, and after keeping for 30s, turn off the power supply, and the furnace cools down to room temperature at 1~10°C / min, take out sample.

Embodiment 2

[0028] The NBT ceramic powder was pressed into a dog-bone-shaped green body by molding technology, and then pressed under 200MPa cold isostatic pressing for 180s. Place the NBT ceramic green body in the sintering furnace, and connect the green body to the DC high voltage power supply through platinum wires, such as figure 1 shown. Set the electric field to 140V / cm, and the limiting current density to 30mA / mm 2 , then raise the temperature of the sintering furnace from room temperature to 910°C, the heating rate is 10°C / min, the power supply is changed from constant voltage mode to constant current mode, after keeping for 30s, turn off the power supply, and the furnace cools down to room temperature at 1~10°C / min, take out sample.

Embodiment 3

[0030] The NBT ceramic powder was pressed into a dog-bone-shaped green body by molding technology, and then pressed under 200MPa cold isostatic pressing for 180s. Place the NBT ceramic green body in the sintering furnace, and connect the green body to the DC high voltage power supply through platinum wires, such as figure 1 shown. Set the electric field to 160V / cm, and the limiting current density to 30mA / mm 2 , then raise the temperature of the sintering furnace from room temperature to 960, the heating rate is 10°C / min, the power supply is changed from constant voltage mode to constant current mode, after keeping for 30s, turn off the power supply, and the furnace cools down to room temperature at 1~10°C / min, take out sample.

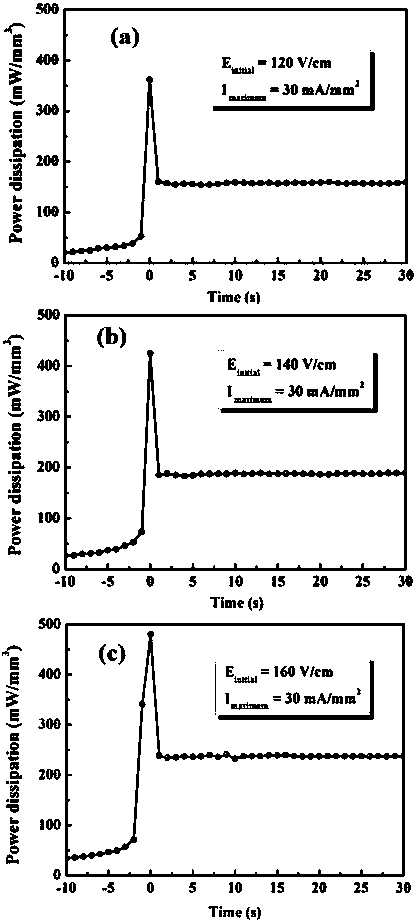

[0031] figure 2 It is the change curve of current density with furnace temperature for different electric fields (120V / cm, 140V / cm, 160V / cm). It can be seen from the figure that the corresponding rapid sintering temperature of ceramics decreases s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com