Preparation method of mesoporous silica-carbon composite material

A technology of mesoporous silica and carbon composite materials, applied in the direction of preparation/purification of silica and carbon, silicon oxide, etc., can solve the problems of complex steps and high cost, and achieve high repetition rate, low cost and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

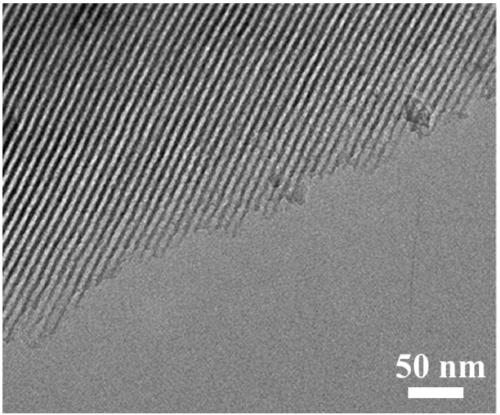

[0026] A method for preparing a mesoporous silica-carbon composite material, comprising:

[0027] (1) Dilute the concentrated sulfuric acid into water to prepare a dilute sulfuric acid solution with a concentration of 1.0wt%;

[0028] Disperse 0.2g of mesoporous silica-hexadecyltrimethylammonium bromide composite material into 4mL of dilute sulfuric acid solution, and ultrasonically disperse to form a uniform solution;

[0029] (2) Dry the mixed system in step (1) at a temperature of 100°C for 6 hours to obtain a mesoporous silica-hexadecyltrimethylammonium bromide-sulfuric acid composite material; after drying , transferred to a 160°C oven for pre-carbonization to obtain a mesoporous silica-low polycarbon composite material;

[0030] (3) Put the above-mentioned mesoporous silica-low polycarbon composite material in a tube furnace, raise the temperature from room temperature to 600° C. under an inert gas atmosphere, and keep it for 6 hours, with a heating rate of 1° C. / min. ...

Embodiment 2

[0033] (1) the concentrated sulfuric acid is diluted in water, and preparation concentration is the dilute sulfuric acid solution of 2.5wt%;

[0034] Disperse 0.04g of mesoporous silica-octadecyltrimethylammonium chloride composite material into 4mL of dilute sulfuric acid solution, and ultrasonically disperse to form a uniform solution;

[0035] (2) Dry the mixed system in step (1) at a temperature of 60°C for 6 hours to obtain a mesoporous silica-octadecyltrimethylammonium chloride-sulfuric acid composite material; after drying , transferred to a 150°C oven for pre-carbonization to obtain a mesoporous silica-low polycarbon composite material;

[0036] (3) Put the above-mentioned mesoporous silica-low polycarbon composite material in a tube furnace, raise the temperature from room temperature to 800°C under an inert gas atmosphere, and keep it for 4h, with a heating rate of 5°C / min, A mesoporous silica-carbon composite was obtained.

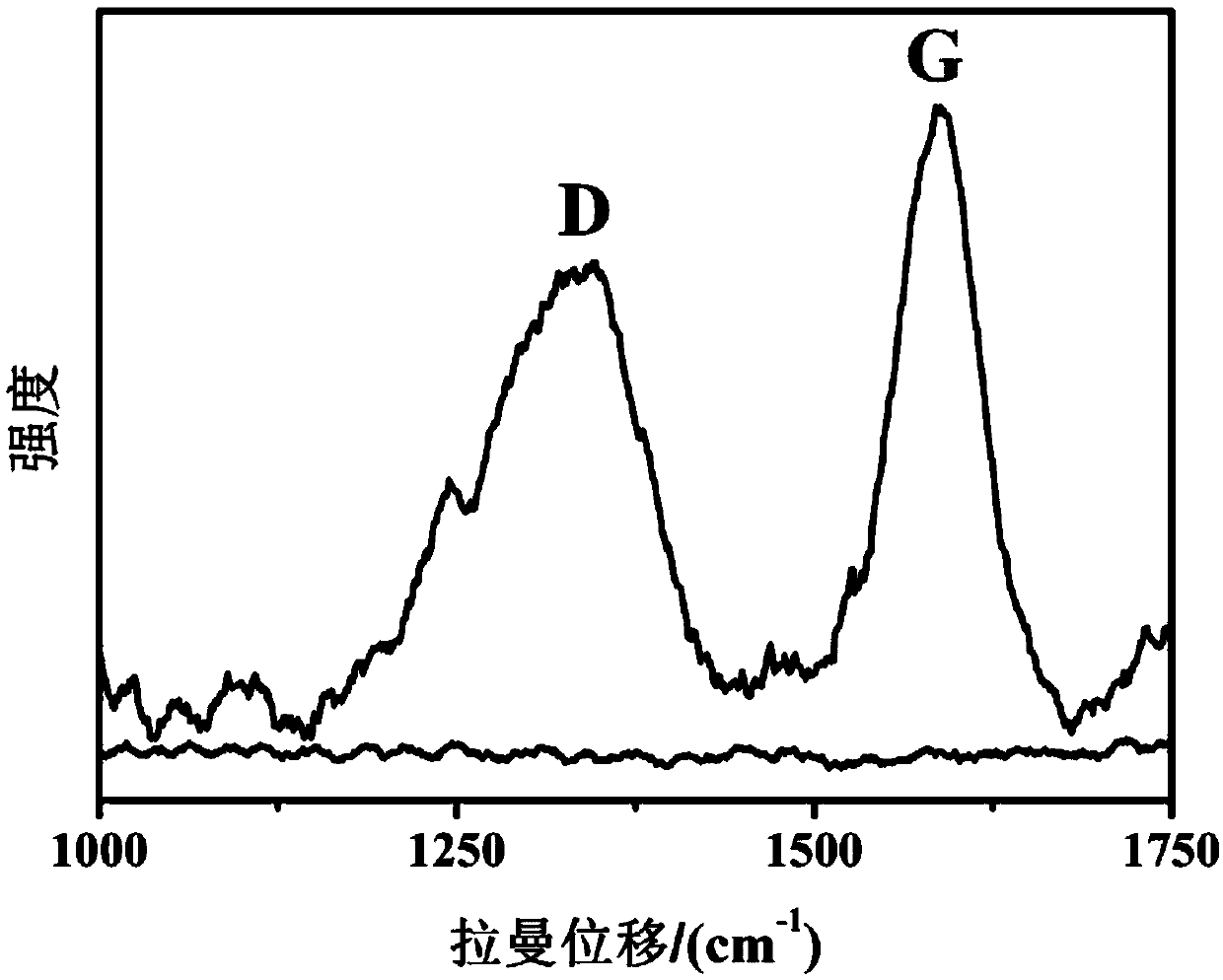

[0037] The mesoporous silicon dioxide-l...

Embodiment 3

[0039] (1) dilute the concentrated sulfuric acid into water, prepare the dilute sulfuric acid solution that concentration is 5.0wt%;

[0040] Disperse 0.004g of mesoporous silica-F127 composite material into 4mL of dilute sulfuric acid solution, and ultrasonically disperse to form a uniform solution;

[0041] (2) Dry the mixed system in step (1) at a temperature of 80°C for 10 hours to obtain a mesoporous silica-F127-sulfuric acid composite material; after drying, transfer it to an oven at 180°C for pre-carbonization , to obtain mesoporous silica-low polycarbon composite material;

[0042] (3) Put the above-mentioned mesoporous silica-low polycarbon composite material in a tube furnace, raise the temperature from room temperature to 900°C under an inert gas atmosphere, and keep it for 3h, the heating rate is 10°C / min, A mesoporous silica-carbon composite was obtained.

[0043] The mesoporous silicon dioxide-low polycarbon composite material obtained above is a skeleton forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com