Atomizer of electronic cigarette and preparation method of electronic cigarette and atomizing assembly

A technology of electronic cigarette atomizer and atomization components, which is applied in the field of electronic cigarettes and can solve the problems of resistance consistency and lack of combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

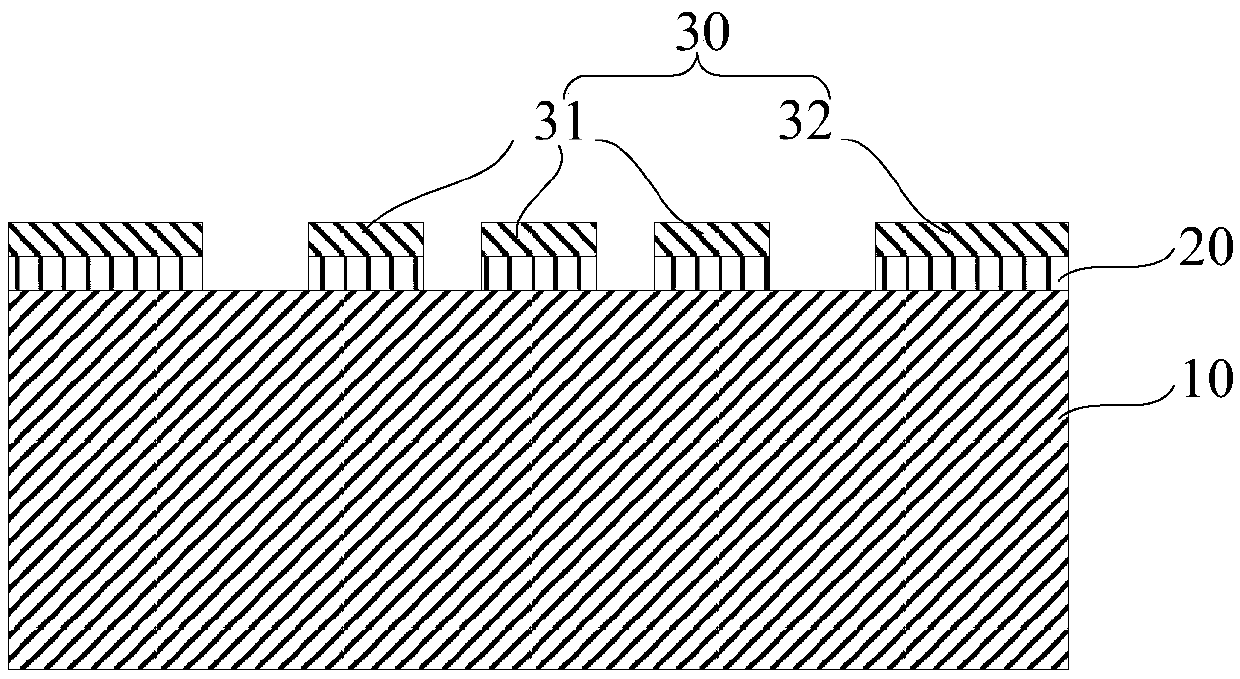

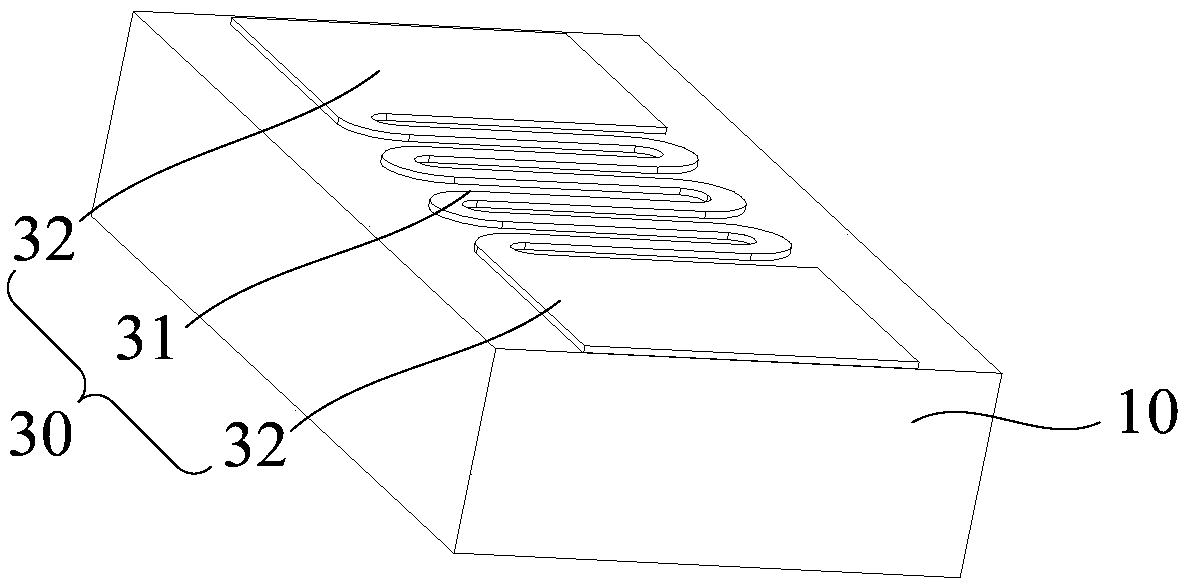

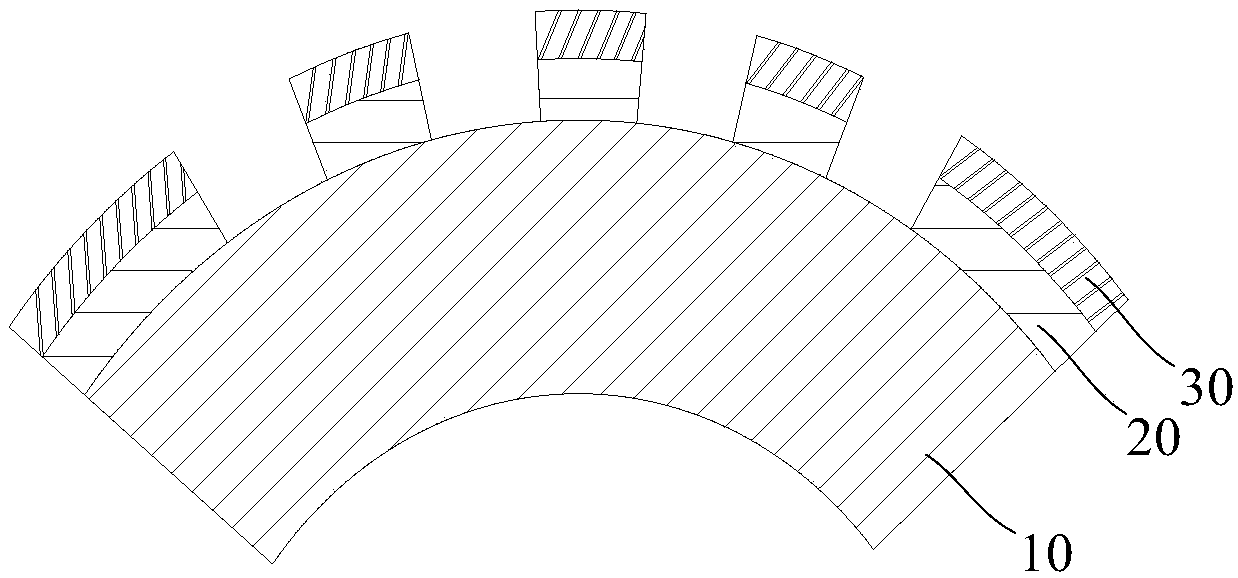

[0043] The present invention also proposes a mass preparation method of the atomization assembly, which can have more firm combination stability and uniform resistance stability as a whole compared with the conventional atomization assembly of the porous ceramic thick film heating circuit. Specifically, the method for preparing a large number of atomized components with uniform and stable resistance includes the following steps:

[0044] S10, such as Figure 5 As shown, obtain a sheet-shaped base material 30a, etch the sheet-shaped heating base material with an etching solution according to the shape and structure of the required heating element 30, and then form the heating element 30 after removing the excess part;

[0045] S20, such as Figure 6 As shown, the porous body 10 is obtained, and a template 40 is covered on the surface of the porous body 10 configured as an atomizing surface; the template 40 has a hollow pattern 41 that is adapted to the shape of the heating ele...

Embodiment 1

[0063] S10, the nickel-chromium sheet with a thickness of 50 μm is used in common hydrofluoric acid / hydrochloric acid mixed etching solution according to the Figure 5 The pattern shape shown is etched to obtain Figure 5 The etch product containing several heat generating elements 30 is shown.

[0064] S20, obtain a zirconia porous ceramic plate 10 with a size of 150*150*2mm as a substrate, and cover one of the surfaces as an atomized surface Figure 6 template 40 as shown;

[0065] S30, print on the template 40 to form the glass paste layer 20a, and stop when the thickness of the glass paste layer 20a is 50 μm; wherein, the glass paste adopts 70% of glass powder, 15% of ethyl cellulose, and propylene glycol monomethyl ether. 10%, dioctyl phthalate 3%, paraffin 2% mixed preparation; glass powder includes SiO 2 50%, B 2 o 3 25%, CaO10%, ZnO15%.

[0066] S40, after removing the template 40, mount the etching product formed by etching in step S10 according to the pattern o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com