Method and device for measuring material radiance based on millimeter wave

A testing method, millimeter-wave technology, applied to measuring devices, using microwave means for material analysis, analyzing materials, etc., can solve problems such as complex measurement operations, interference of measurement results, and errors, and achieve simple operation, reduced test errors, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

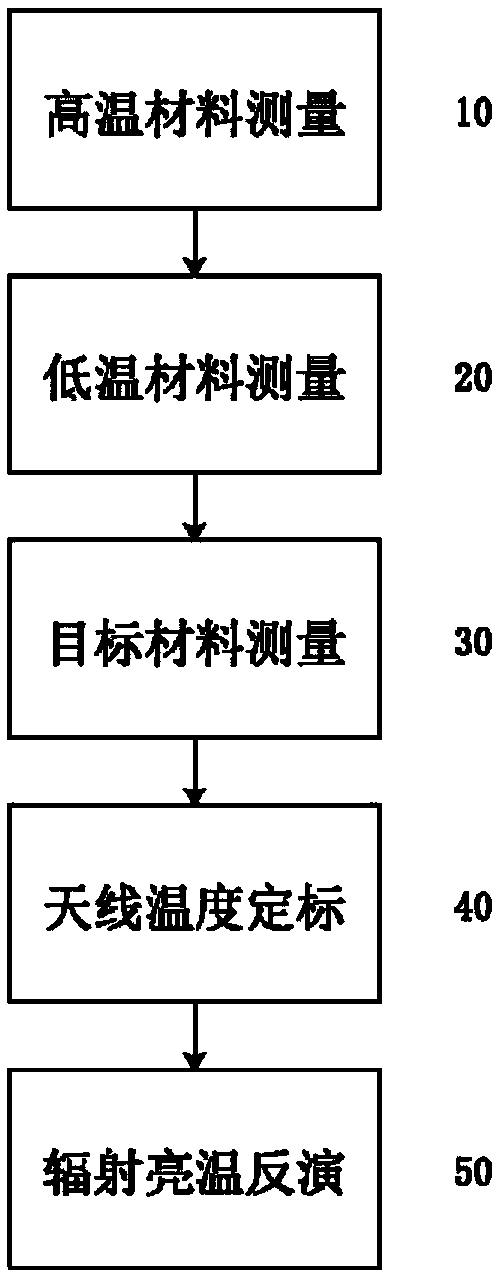

[0022] Such as figure 1 As shown, the material emissivity testing method based on millimeter waves of the present invention comprises the following steps:

[0023] (10) High-temperature material measurement: use millimeter waves to measure the radiation characteristics and temperature of blackbody materials;

[0024] (20) Cryogenic material measurement: use millimeter waves to measure the radiation characteristics and temperature of liquid nitrogen;

[0025] (30) Target material measurement: use millimeter waves to measure the radiation characteristics and temperature of the target material;

[0026] (40) Antenna temperature calibration: according to the calibration equation, the temperature of the antenna is calibrated by using the temperature of the blackbody material and the temperature of liquid nitrogen;

[0027] (50) Radiation brightness temperature inversion: According to the calibrated antenna temperature, the radiation brightness temperature is obtained by inversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com