A treatment method for eliminating the odor of polyester fabric and improving its moisture absorption and quick-drying performance

A polyester fabric and treatment method technology, applied in physical treatment, fiber treatment, textiles and papermaking, etc., can solve the problems of affecting the hygroscopic performance of the fabric, difficult to anchor β-cyclodextrin, and the fabric is strong and destructive, etc. Large-scale operation, improve moisture absorption, avoid the effect of fabric yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

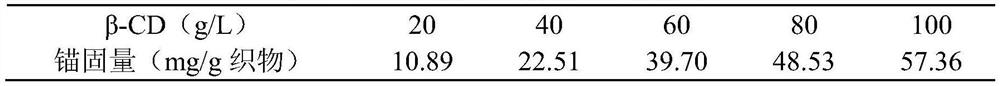

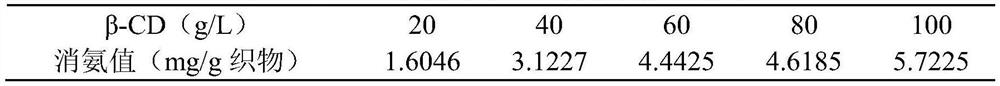

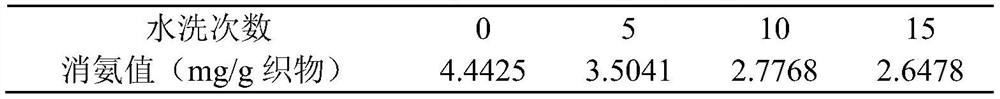

[0035] Prepare 20g / L plant ash solution, heat the fabric and plant ash solution at a ratio of 1:30 at 95°C for 60 minutes, wash the fabric with water until the extruded droplets are neutral, and prepare a concentration of 20g / L β- CD solution, mix the citric acid solution with a concentration of 100g / L and the β-CD solution evenly, dip the fabric in the mixed solution for 30 minutes, after two dipping and two rolling treatments, the rolling rate is 80%, pre-baking at 90°C, plasma The atmosphere is hydrogen, argon, nitrogen, oxygen, air or a mixture of one or more of the above gases and a small amount of lemon or mint flavor gas, lemon or mint flavor gas and hydrogen, argon, nitrogen, oxygen, air or one or more The volume ratio of the above gas mixture is 1:80, the power level is 1-5, the flow rate is 1-3L / min, and the processing time is 0.5-4min. After plasma treatment, deodorizing performance and moisture absorption and quick-drying performance are obtained after the treated ...

Embodiment 2

[0037]Prepare 15g / L plant ash solution, heat the fabric and plant ash solution at a ratio of 1:25 at 95°C for 60 minutes, wash the fabric with water until the extruded droplets are neutral, and prepare a concentration of 40g / L β- CD solution, mix the citric acid solution with a concentration of 100g / L and the β-CD solution evenly, dip the fabric in the mixed solution for 20 minutes, after two dipping and two rolling treatments, the rolling rate is 80%, pre-baked at 90°C, plasma The atmosphere is hydrogen, argon, nitrogen, oxygen, air or a mixture of one or more of the above gases and a small amount of lemon or mint flavor gas, lemon or mint flavor gas and hydrogen, argon, nitrogen, oxygen, air or one or more The volume ratio of the above gas mixture is 1:80, the power level is 1-5, the flow rate is 1-3L / min, and the processing time is 0.5-4min. After plasma treatment, deodorizing performance and moisture absorption and quick-drying performance are obtained after the treated po...

Embodiment 3

[0039] Prepare 25g / L plant ash solution, heat the fabric and plant ash solution at a ratio of 1:35 at 95°C for 60 minutes, wash the fabric with water until the extruded droplets are neutral, and prepare a concentration of 60g / L β- CD solution, mix the citric acid solution with a concentration of 100g / L and the β-CD solution evenly, dip the fabric in the mixed solution for 30 minutes, after two dipping and two rolling treatments, the rolling rate is 80%, pre-baking at 90°C, plasma The atmosphere is hydrogen, argon, nitrogen, oxygen, air or a mixture of one or more of the above gases and a small amount of lemon or mint flavor gas, lemon or mint flavor gas and hydrogen, argon, nitrogen, oxygen, air or one or more The volume ratio of the above gas mixture is 1:80, the power level is 1-5, the flow rate is 1-3L / min, and the processing time is 0.5-4min. After plasma treatment, deodorizing performance and moisture absorption and quick-drying performance are obtained after the treated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com