A kind of preparation method of moisture-absorbing quick-drying fabric

A moisture-absorbing and quick-drying fabric technology, which is applied in knitting, weaving, filament/thread forming, etc., to achieve the effect of improving moisture-absorbing and quick-drying performance, simple method, and improved moisture-conducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a moisture-absorbing quick-drying fabric, the process of which is as follows:

[0036] (1) Preparation of textured yarn fully drawn filament:

[0037] (1.1) Prepare FDY from high-viscosity PET (intrinsic viscosity 80dL / g) and low-viscosity PET (intrinsic viscosity 0.55dL / g) with a mass ratio of 50:50 according to the FDY process and the process of round sheath-core composite fibers Silk;

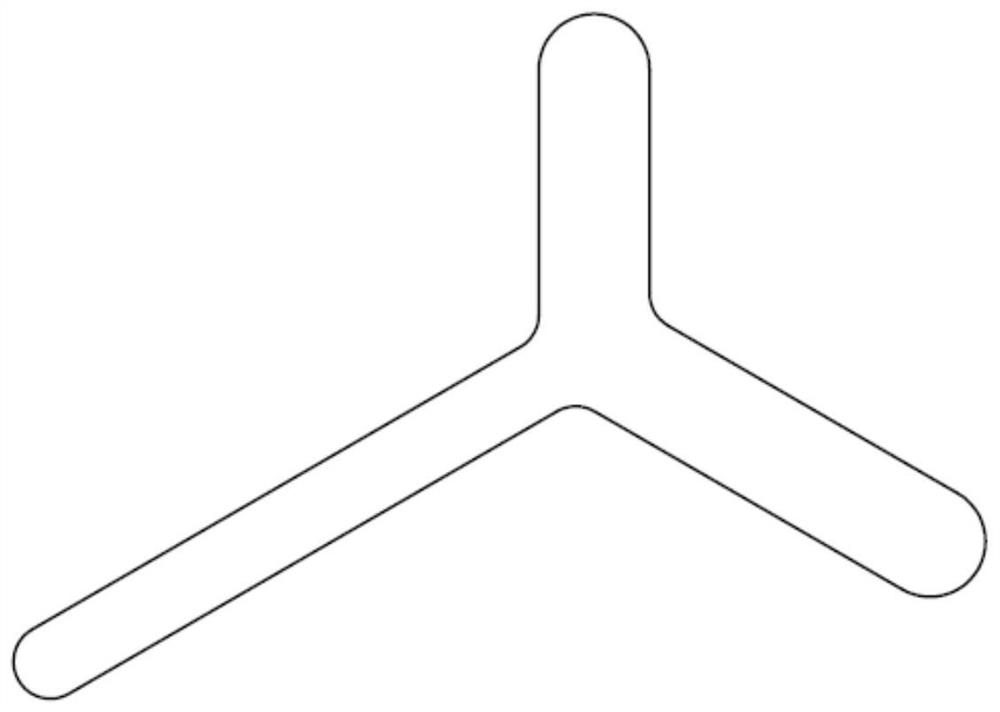

[0038] Among them, the spinneret hole on the spinneret is changed from circular to trilobal, the ratio of the length of the three lobes of the same three-lobed spinneret is 1.0:1.4:2.2, and the corresponding ratio of the width of the three lobes is 1.5 : 1.5:1, the ratio of the length and width of the shortest lobe is 3.5:1, and the angle between the centerlines of the adjacent two lobes is 120°; the shape and size of different trilobal spinneret holes are the same;

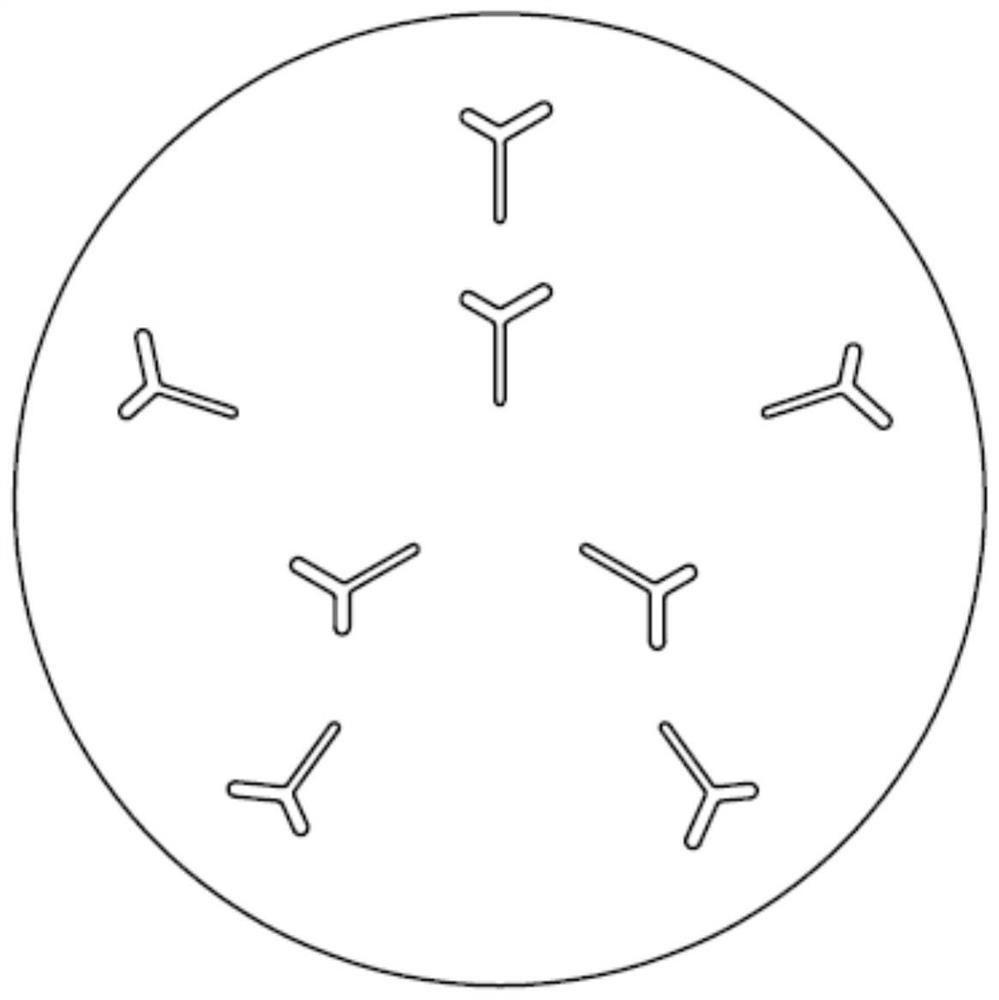

[0039] Use ring blowing to cool, and control the arrangement of the three-lobed spinneret hol...

Embodiment 2

[0047] A method for preparing a moisture-absorbing quick-drying fabric, the process of which is as follows:

[0048] (1) Preparation of textured yarn fully drawn filament:

[0049] (1.1) Prepare FDY from high-viscosity PET (intrinsic viscosity 78dL / g) and low-viscosity PET (intrinsic viscosity 0.55dL / g) with a mass ratio of 50:50 according to the FDY process and the process of round sheath-core composite fibers Silk;

[0050] Among them, the spinneret hole on the spinneret is changed from circular to trilobal, the ratio of the length of the three lobes of the same three-lobed spinneret is 1.0:1.1:2.0, and the corresponding ratio of the width of the three lobes is 1.5 : 1.5:1, the ratio of the length of the shortest lobe to the width is 3.4:1, and the angle between the centerlines of the adjacent two lobes is 120°; the shape and size of different trilobal spinneret holes are the same;

[0051] Use ring blowing to cool, and control the arrangement of the three-lobed spinneret ...

Embodiment 3

[0059] A method for preparing a moisture-absorbing quick-drying fabric, the process of which is as follows:

[0060] (1) Preparation of textured yarn fully drawn filament:

[0061] (1.1) Prepare FDY from high-viscosity PET (intrinsic viscosity 75dL / g) and low-viscosity PET (intrinsic viscosity 0.5dL / g) with a mass ratio of 50:50 according to the FDY process and the process of round sheath-core composite fibers Silk;

[0062] Among them, the spinneret hole on the spinneret is changed from circular to trilobal, the ratio of the length of the three lobes of the same three-lobed spinneret is 1.0:1.2:2.3, and the corresponding ratio of the width of the three lobes is 1.5 : 1.5:1, the ratio of the length of the shortest lobe to the width is 3.2:1, and the angle between the centerlines of the adjacent two lobes is 120°; the shape and size of different trilobal spinneret holes are the same;

[0063] Use ring blowing to cool, and control the arrangement of the three-lobed spinneret h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com