Polyester HOY (High-Oriented Fibre) and preparation method thereof

A HOY, fiber technology, applied in the field of polyester HOY fiber and its preparation, can solve the problems of polyester fiber coloring difficulty, polyester dyeing difficulty, poor hygroscopicity, etc., to shorten the dyeing time, reduce energy consumption, and reduce dyeing costs. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of polyester HOY fiber, the steps are as follows:

[0041] (1) prepare modified polyester;

[0042] (1.1) Esterification reaction;

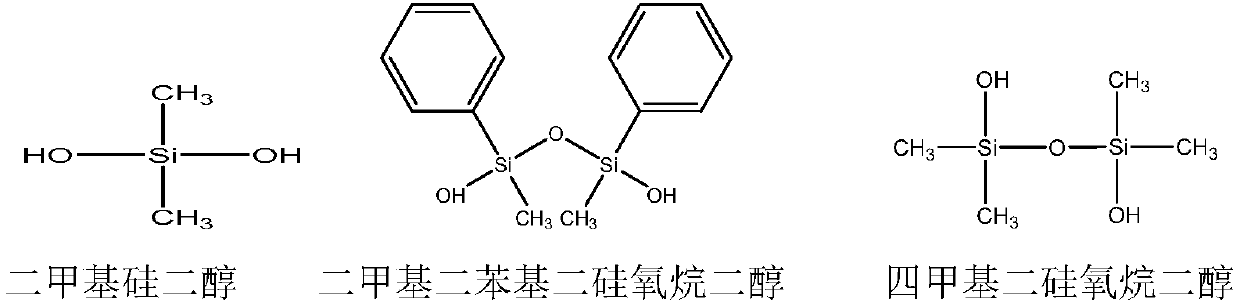

[0043] Make a slurry of terephthalic acid, ethylene glycol, and dimethylsilanediol, add antimony trioxide, titanium dioxide, and triphenyl phosphate and mix evenly, pressurize in a nitrogen atmosphere for esterification, pressurize The pressure is 0.3MPa, the temperature of the esterification reaction is 250°C, when the amount of water distilled in the esterification reaction reaches 95% of the theoretical value, it is the end point of the esterification reaction, and the molar ratio of phthalic acid to ethylene glycol is 1: 1.2, the addition of dimethylsilanediol is 3mol% of the addition of terephthalic acid, the addition of antimony trioxide, titanium dioxide and triphenyl phosphate is 0.03wt%, 0.22wt% of the addition of terephthalic acid wt% and 0.02wt%;

[0044] (1.2) polycondensation reaction;

[0045] After t...

Embodiment 2

[0058] A preparation method of polyester HOY fiber, the steps are as follows:

[0059] (1) prepare modified polyester;

[0060] (1.1) Esterification reaction;

[0061] Make a slurry of terephthalic acid, ethylene glycol, and dimethyldiphenyldisiloxane diol, add antimony trioxide, titanium dioxide, and trimethyl phosphate, mix evenly, and pressurize in a nitrogen atmosphere. For esterification reaction, the pressurized pressure is 0.2MPa, and the temperature of the esterification reaction is 252°C. When the amount of water distilled in the esterification reaction reaches 90% of the theoretical value, it is the end point of the esterification reaction. Among them, phthalic acid and ethylene glycol The molar ratio of alcohol is 1:1.5, the addition of dimethyl diphenyl disiloxane diol is 3.2mol% of the addition of terephthalic acid, the addition of antimony trioxide, titanium dioxide and trimethyl phosphate Respectively 0.04wt%, 0.20wt% and 0.04wt% of the amount of terephthalic ...

Embodiment 3

[0071] A preparation method of polyester HOY fiber, the steps are as follows:

[0072] (1) prepare modified polyester;

[0073] (1.1) Esterification reaction;

[0074] Make a slurry of terephthalic acid, ethylene glycol, and tetramethyldisiloxane diol, add ethylene glycol antimony, titanium dioxide, and trimethyl phosphite, mix evenly, and pressurize in a nitrogen atmosphere for esterification Reaction, pressurized pressure is 0.1MPa, the temperature of esterification reaction is 255 ℃, when the amount of water distilled in the esterification reaction reaches 92% of the theoretical value, it is the end point of the esterification reaction, wherein the phthalic acid and ethylene glycol The molar ratio is 1:1.3, the addition amount of tetramethyldisiloxane diol is 3.5mol% of the addition amount of terephthalic acid, the addition amount of ethylene glycol antimony, titanium dioxide and trimethyl phosphite is respectively 0.05wt%, 0.24wt% and 0.01wt% of the amount of diformic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com