Method for preparing two-dimensional layered MoS2 material through molten salt electrochemical intercalation method

A two-dimensional layered, electrochemical technology, applied in the electrolytic process, electrolytic components, etc., can solve the problems that affect the electrochemical performance of MoS2, limit the size and layer distribution of two-dimensional materials, and the shape and thickness are difficult to control, so as to improve the electrochemical performance. Effects of chemical properties, low cost, and low precursor requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

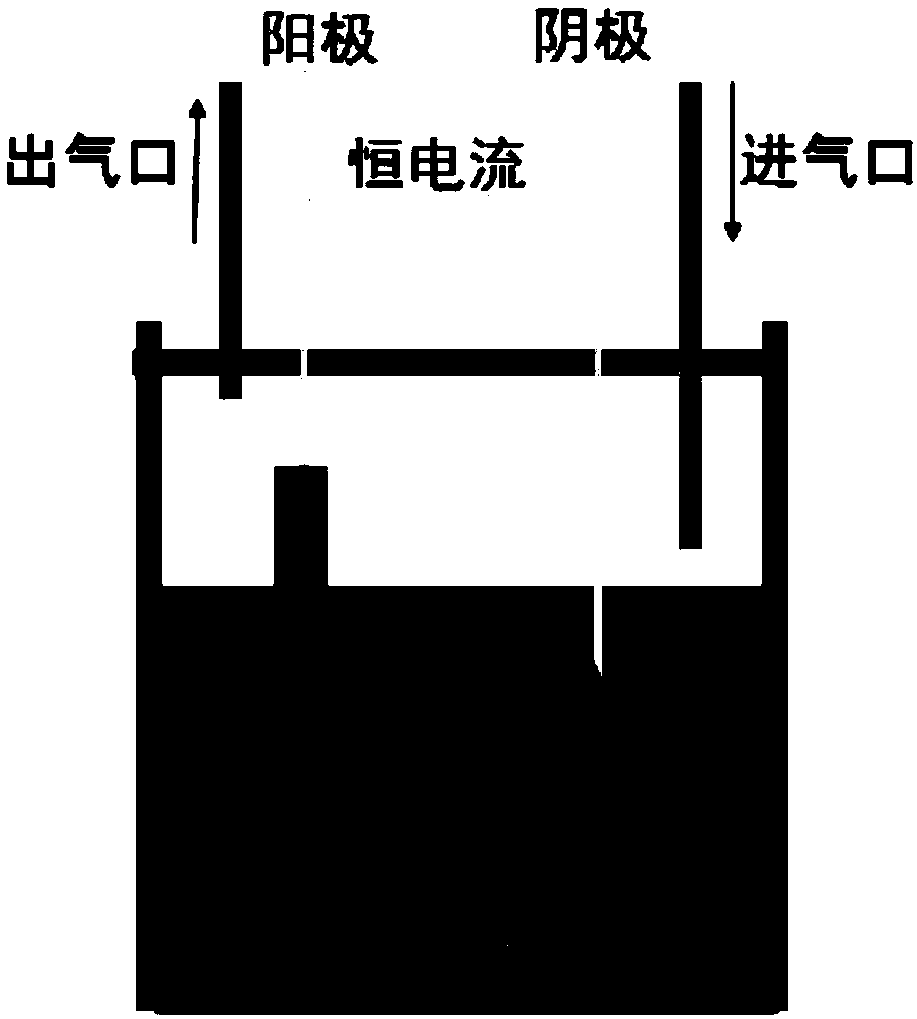

Image

Examples

Embodiment 1

[0056] Preparation of two-dimensional layered MoS by a molten salt electrochemical intercalation method 2 Material method, proceed as follows:

[0057] In this embodiment, the molten salt used is a chloride molten salt, specifically NaCl-CaCl 2 The mixture, by molar ratio, NaCl:CaCl 2 =0.479:0.521.

[0058] Step 1: Preparation

[0059] (1) NaCl and CaCl 2 salt pretreatment

[0060] Weigh NaCl and CaCl according to the distribution ratio of molten salt raw materials 2 , NaCl and CaCl 2 Grinding separately to obtain NaCl and CaCl with a particle size of 2mm 2 , poured into beakers after grinding, and placed in a muffle furnace to seal;

[0061] In a vacuum state, the muffle furnace was heated up to 200°C at a heating rate of 3°C / min, and the temperature was maintained for 12 hours for pretreatment to remove the water in the molten salt raw material, and then cooled to room temperature to take out the molten salt to obtain dehydrated NaCl and dehydrated CaCl 2 ;

[006...

Embodiment 2

[0078] Preparation of two-dimensional layered MoS by a molten salt electrochemical intercalation method 2 Material method, proceed as follows:

[0079] In this embodiment, the molten salt used is a chloride molten salt, specifically a mixture of LiCl-KCl, with a molar ratio of LiCl:KCl=0.592:0.408.

[0080] Step 1: Pretreatment of LiCl and KCl salts

[0081] Weigh LiCl and KCl according to the distribution ratio of molten salt raw materials, grind LiCl and KCl respectively to obtain LiCl and KCl with a particle size of 1.5 mm, pour them into beakers after grinding, and place them in a muffle furnace to seal;

[0082] In a vacuum state, the muffle furnace was heated up to 300°C at a heating rate of 4°C / min, and kept at a constant temperature for 12 hours for pretreatment to remove the water in the molten salt raw material, and then cooled to room temperature to take out the molten salt to obtain dehydrated LiCl and KCl after dehydration;

[0083] (2) Preparation of electrode...

Embodiment 3

[0096] Preparation of two-dimensional layered MoS by a molten salt electrochemical intercalation method 2 Material method, proceed as follows:

[0097] In this embodiment, the molten salt used is a chloride molten salt, specifically MgCl 2 -Mixture of NaCl-KCl, in molar ratio, MgCl 2 : NaCl: KCl = 0.454: 0.33: 0.216.

[0098] Step 1: Preparation

[0099] (1) MgCl 2 , NaCl and KCl salt pretreatment

[0100] With embodiment 1, difference is:

[0101] 1) In step 1, the MgCl 2 , NaCl and KCl grinding;

[0102] 2) In step 1, obtain dehydrated MgCl respectively 2 , NaCl after dehydration and KCl salt after dehydration.

[0103] (2) Preparation of electrodes

[0104] With embodiment 1;

[0105] Step 2: Assembly of the reaction system

[0106] With embodiment 1, difference is:

[0107] 1) In (2) of step 2, the MgCl after 275g dehydration 2 , 122.75g of dehydrated NaCl and 102.25g of dehydrated KCl were put into the corundum crucible.

[0108] 2) In (3) of step 2, keep t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com