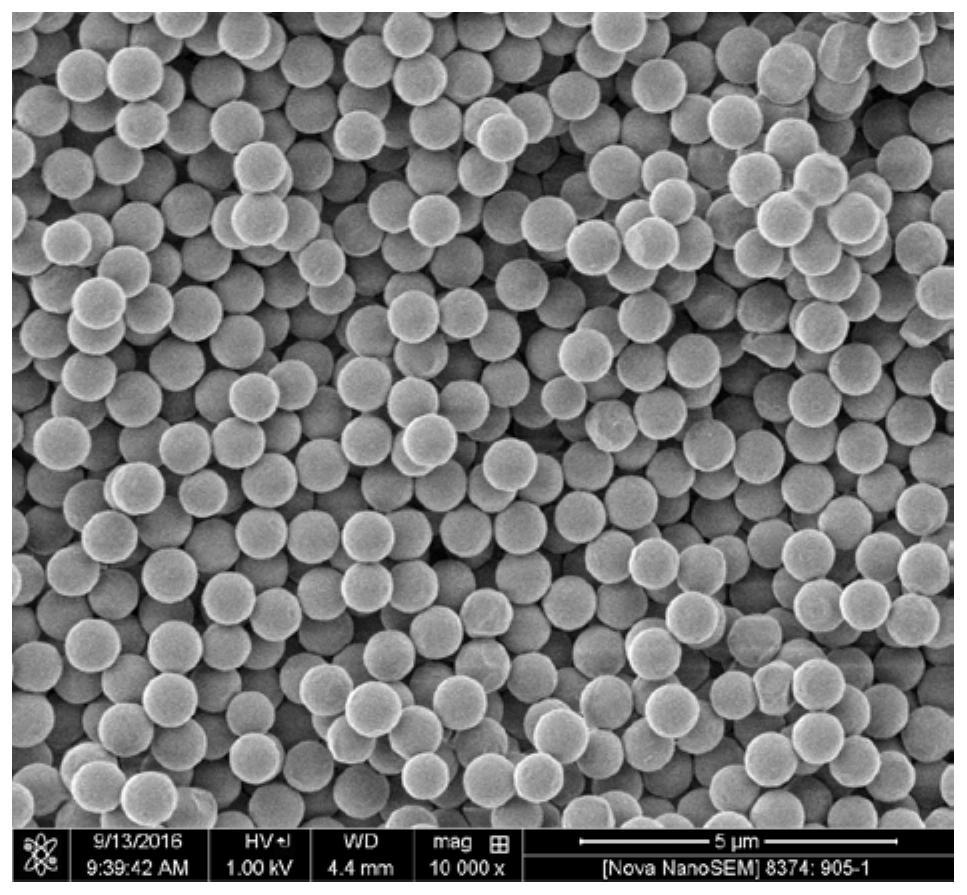

Multi-network monodisperse polyacrylamide polymer gel microspheres and preparation method thereof

A technology of polyacrylamide and gel microspheres, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of insufficient stability of polymer microspheres, achieve uniform particle size, long service life, good The effect of blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 30 parts of acrylamide, 15 parts of methacryloxyethyltrimethylammonium chloride, 15 parts of 2-acrylamido-dimethylpropanesulfonic acid, 5 parts of acrylic acid, 0.02 parts of disodium edetate , 1 part of polyvinyl alcohol, 0.2 part of polyvinyl grade pyrrolidone, 0.2 part of methylenebisacrylamide, 1 part of tert-butylacrylamide dissolved in a mixed solvent of 120 parts of water and 400 parts of ethanol and stirred evenly. The solution was added to the reaction kettle, the stirring rate was 100r / min, the inert gas was passed through, and the temperature of the water bath was 30°C. After continuous stirring for 30 min, the composite initiator system was added dropwise into the reaction kettle respectively. The reaction was continued for 1 hour.

[0050] Dissolve 2 parts of zirconium acetate in a mixed solvent prepared with 6 parts of water and 20 parts of ethanol, slowly drop it into the reaction kettle, adjust the pH value to 3-5 with hydrochloric acid, raise the tempe...

Embodiment 2

[0054] 30 parts of acrylamide, 5 parts of methacryloxyethyltrimethylammonium chloride, 5 parts of 2-acrylamido-dimethylpropanesulfonic acid, 5 parts of acrylic acid, 0.02 parts of disodium edetate , 1 part of polyvinyl alcohol, 0.2 part of polyvinyl grade pyrrolidone, 0.2 part of methylenebisacrylamide, 1 part of tert-butylacrylamide dissolved in a mixed solvent of 120 parts of water and 400 parts of ethanol and stirred evenly. The solution was added to the reaction kettle, the stirring rate was 100r / min, the inert gas was passed through, and the temperature of the water bath was 30°C. After continuous stirring for 30 min, the composite initiator system was added dropwise into the reaction kettle respectively. The reaction was continued for 1 hour.

[0055] Dissolve 2 parts of zirconium acetate in a mixed solvent prepared with 6 parts of water and 20 parts of ethanol, slowly drop it into the reaction kettle, adjust the pH value to 3-5 with hydrochloric acid, raise the tempera...

Embodiment 3

[0059] 30 parts of acrylamide, 15 parts of methacryloxyethyltrimethylammonium chloride, 15 parts of 2-acrylamido-dimethylpropanesulfonic acid, 5 parts of acrylic acid, 0.02 parts of disodium edetate , 1 part of polyvinyl alcohol, 0.2 part of polyvinyl grade pyrrolidone, 0.05 part of methylenebisacrylamide, and 1 part of tert-butylacrylamide were dissolved in a mixed solvent of 120 parts of water and 400 parts of ethanol and stirred evenly. The solution was added to the reaction kettle, the stirring rate was 100r / min, the inert gas was passed through, and the temperature of the water bath was 30°C. After continuous stirring for 30 min, the composite initiator system was added dropwise into the reaction kettle respectively. The reaction was continued for 1 hour.

[0060] Dissolve 2 parts of zirconium acetate in a mixed solvent prepared with 6 parts of water and 20 parts of ethanol, slowly drop it into the reaction kettle, adjust the pH value to 3-5 with hydrochloric acid, raise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| drag coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com